Method for producing biological fermentation compound fertilizer by fermenting organic waste water with glutamic acid

A technology for biological fermentation and organic wastewater, applied in organic fertilizers, sewage/sludge fertilizers, fertilization devices, etc., can solve the problems of difficult organic waste gas treatment, difficulty in decomposing soil microorganisms, and increased economic burden on enterprises. The benefits and environmental benefits are obvious, the social and environmental benefits are significant, and the effect of solving the secondary pollution phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

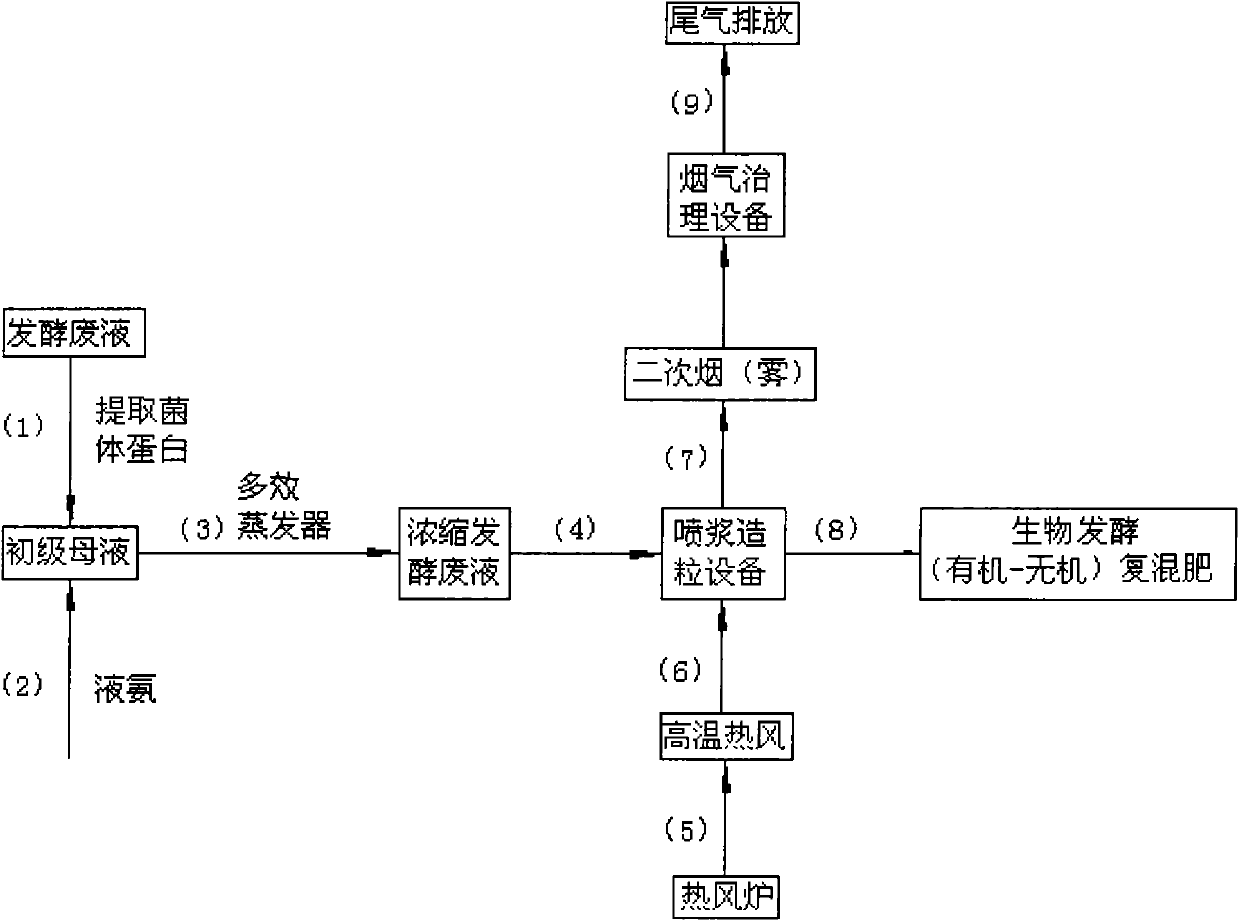

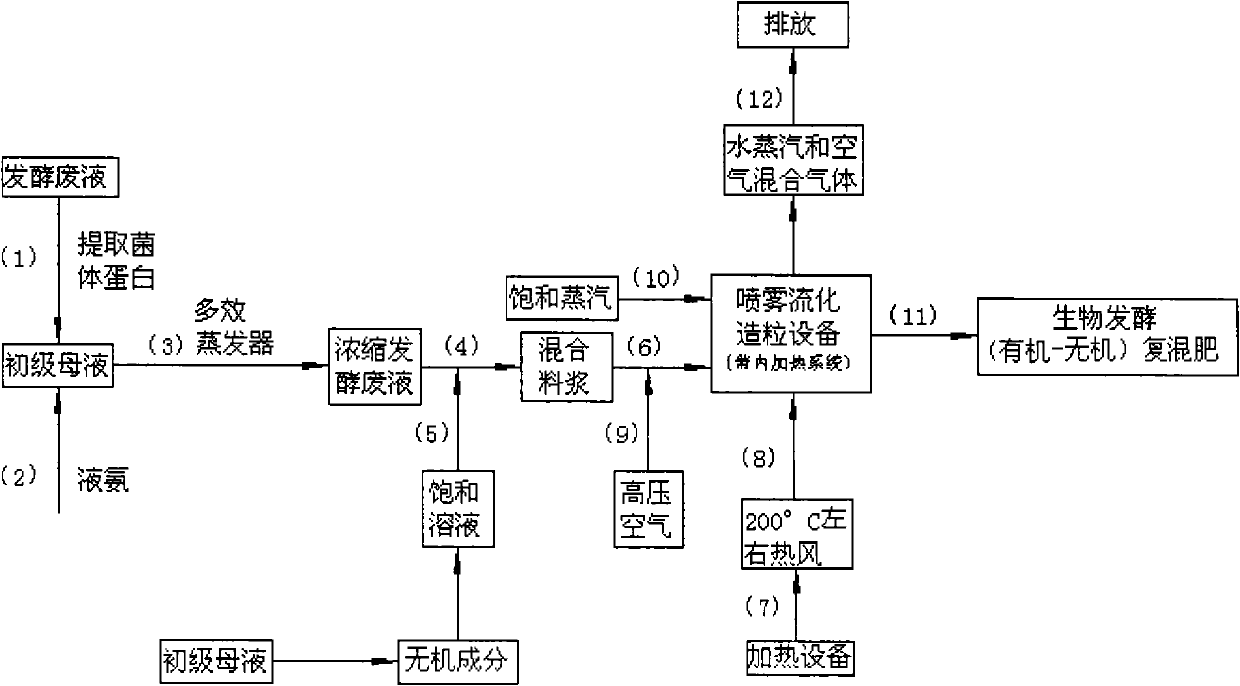

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1, production biological fermentation nitrogen and potassium compound fertilizer (N15-K5)

[0041] Concentrate the glutamic acid fermentation waste liquid after extracting bacterial protein to more than 27 Baume with four-effect evaporation concentration equipment, and the solid content is about 40%. Dissolve 48kg of potassium chloride in 107kg of unconcentrated extracted bacterial protein A saturated solution was prepared from glutamic acid fermentation waste liquid, and the saturated solution was mixed with 1000 kg of concentrated fermentation waste liquid to obtain a mixed solution. The solution is sprayed into the spray fluidized granulation equipment through high-pressure air and a spray gun installed in an appropriate position. The air inlet temperature of the main machine of the granulation equipment is 175°C, the temperature of the fluidized bed material layer is 94°C~98°C, and the pressure of the spray gun is 0.22MPa. By adjusting the frequency of th...

Embodiment 2

[0042] Embodiment 2, production biological fermentation nitrogen and phosphorus compound fertilizer (N15-P5)

[0043] Concentrate the glutamic acid fermentation waste liquid after extracting bacterial protein to more than 27 Baume with four-effect evaporation concentration equipment, and the solid content is about 40%. Dissolve 70kg of monoammonium phosphate in 190kg of unconcentrated extracted bacterial protein A saturated solution was prepared from glutamic acid fermentation waste liquid, and the saturated solution was mixed with 1000 kg of concentrated fermentation waste liquid to obtain a mixed solution. The mixed solution is sprayed into the spray fluidized granulation equipment by high-pressure air and a spray gun installed in an appropriate position. The air inlet temperature of the main machine of the granulation equipment is 175°C, the temperature of the fluidized bed material layer is 94°C~98°C, and the pressure of the spray gun is 0.22MPa. By adjusting the frequency...

Embodiment 3

[0044] Embodiment 3, production biological fermentation NPK compound fertilizer (N15-P5-K5)

[0045] Concentrate the glutamic acid fermentation waste liquid after extracting bacterial protein to more than 27 Baume with four-effect evaporation and concentration equipment, and the solid content is about 40%. Dissolve 80kg of monoammonium phosphate and 33kg of potassium chloride in 220kg of unconcentrated extraction A saturated solution was prepared from the glutamic acid fermentation waste liquid after bacterial protein, and the solution was mixed with 1000 kg of concentrated fermentation waste liquid to obtain a mixed solution. The mixed solution is sprayed into the spray fluidized granulation equipment by high-pressure air and a spray gun installed in an appropriate position. The air inlet temperature of the main machine of the granulation equipment is 175°C, the temperature of the fluidized bed material layer is 94°C~98°C, and the pressure of the spray gun is 0.22MPa. By adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com