Method for continuously producing unsaturated aldehyde compound

An aldehyde compound and unsaturated technology, which is applied in the field of continuous production of unsaturated aldehyde compounds, can solve the problems of reducing product yield and increasing process complexity, and achieves the effects of improving product yield, improving raw material utilization rate and reducing side reactions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A 2% NaOH aqueous solution is used as a catalyst in a tank-type stirred reactor. The condensation reaction temperature is 120°C, and the reaction pressure is 0.4MPa. The process flow is attached Figure 4 Shown: the raw material n-butyraldehyde enters the tank-type stirred reactor A through the pipeline b, and undergoes condensation reaction with the alkali catalyst (2% NaOH) solution at a ratio of 1.5:1. Then the reaction mixture is cooled down to 40°C, and enters the chromatograph B through the pipeline c for static separation. The upper organic phase is octenal containing saturated water and a small amount of unreacted n-butyraldehyde material, and the lower water phase is an aqueous solution containing NaOH catalyst. Part of the water phase is discharged to the wastewater treatment system through the pipeline f, and the remaining water phase is circulated back to the tank-type stirred reactor 1 through the pipeline e for recycling. Concentration is 10% fresh NaOH...

Embodiment 2

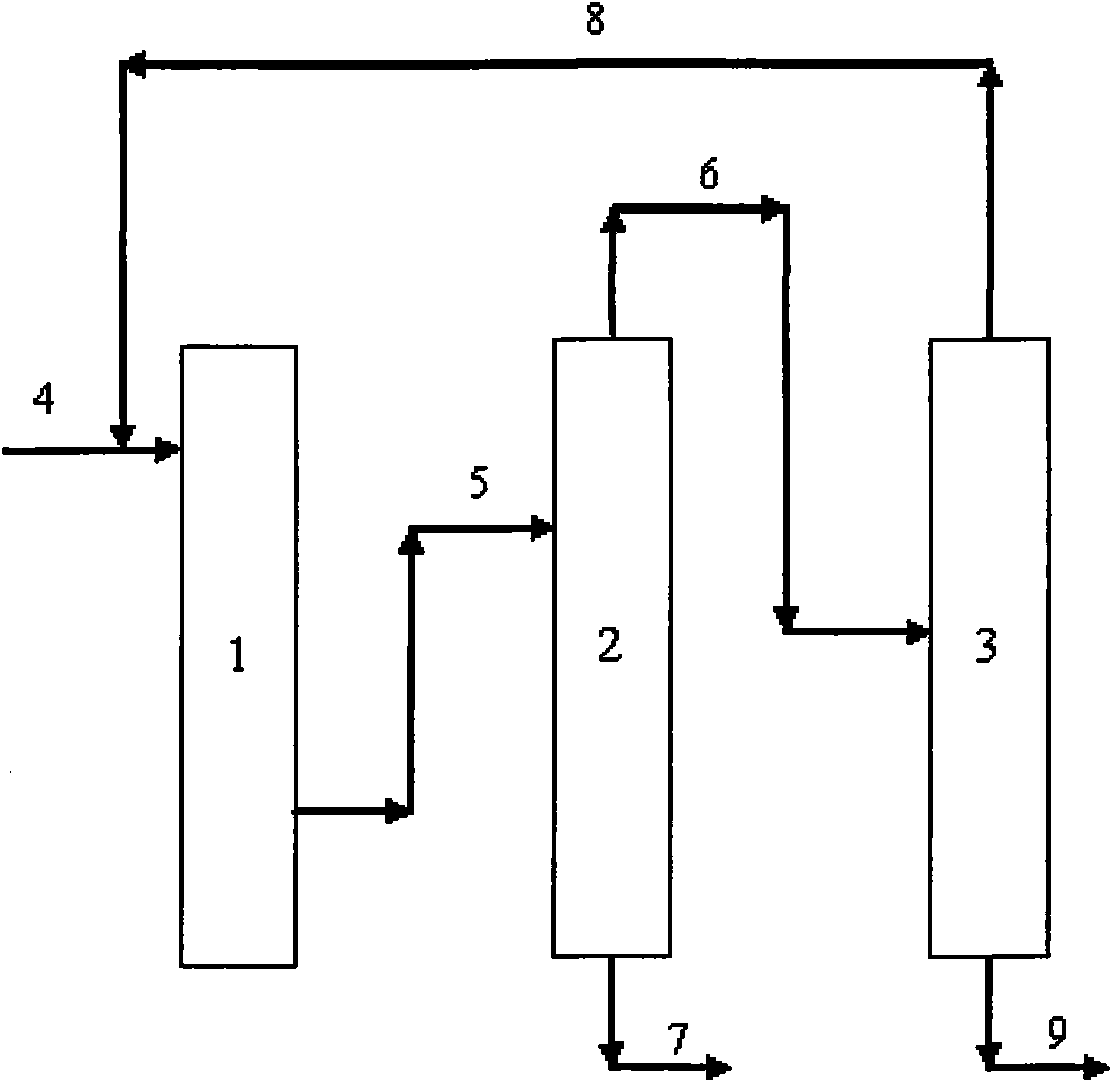

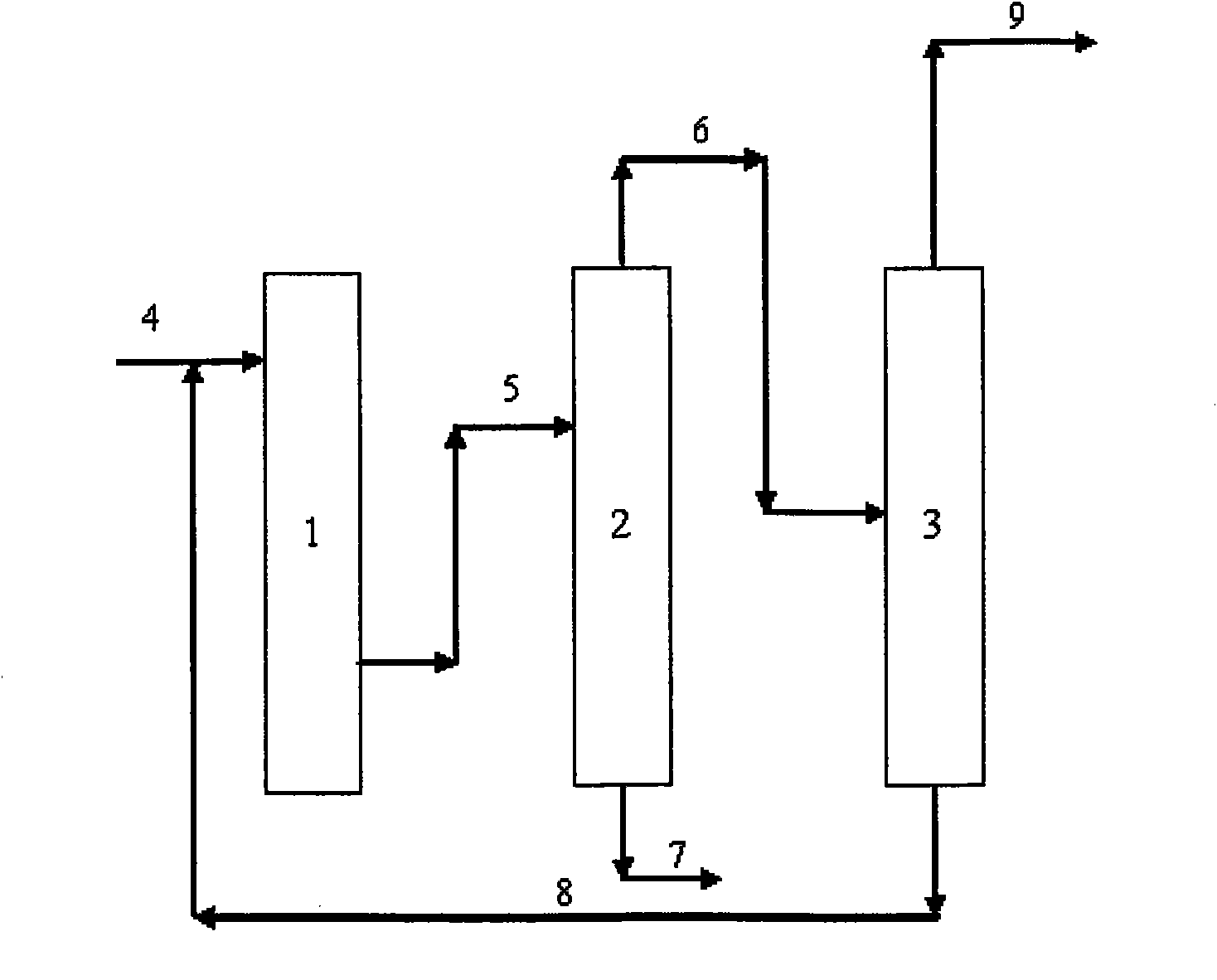

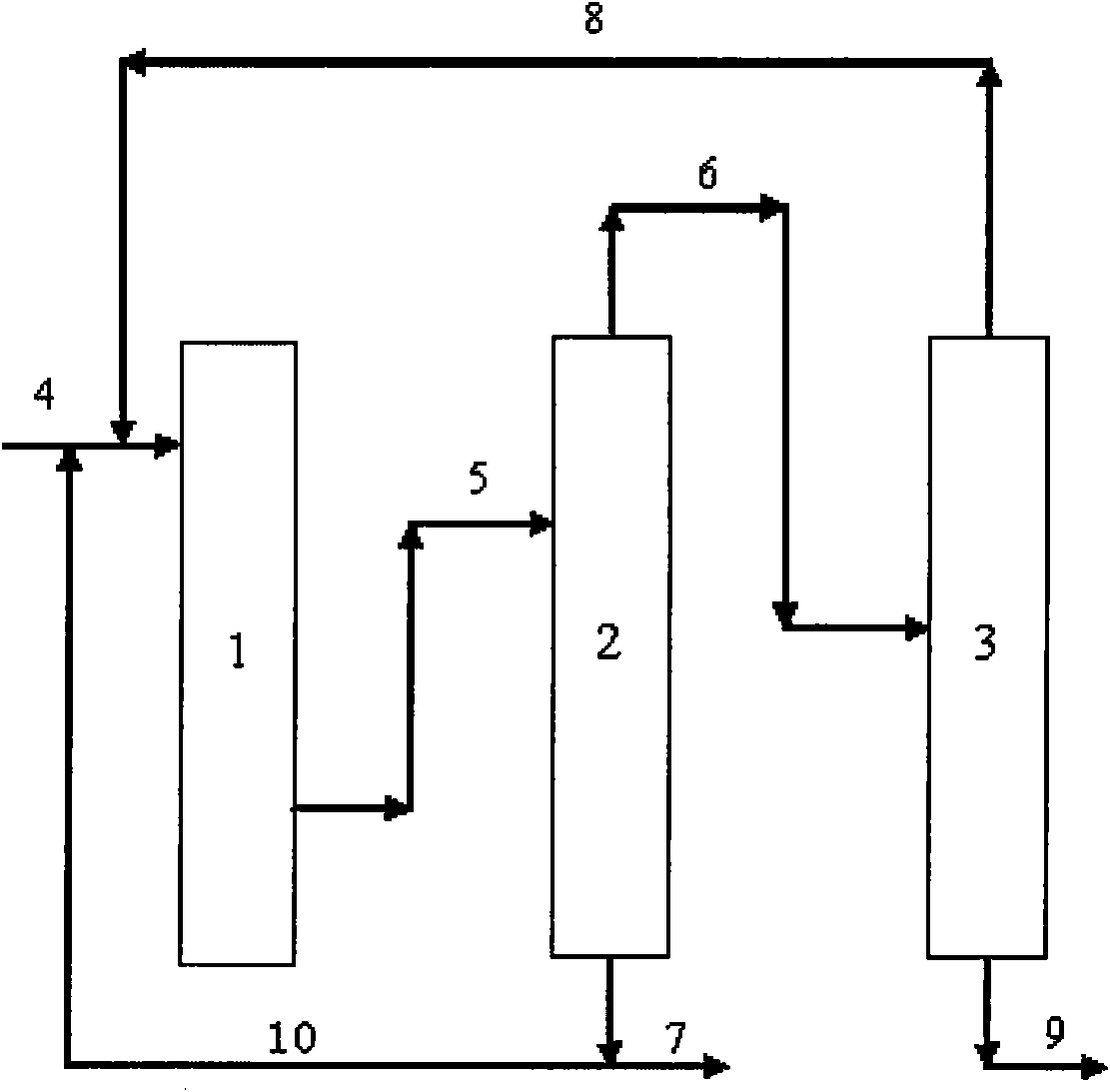

[0045] Embodiment 2 technological process sees figure 1 : N-butyraldehyde enters the fixed bed aldehyde condensation reactor 1 at a flow rate of 5000Kg / h for adiabatic condensation reaction, the reaction temperature at the inlet of the reactor is 150°C, the reaction pressure is 0.7MPa, the catalyst is acidic strip hydrogen ZSM-5 zeolite, alumina As a carrier (95% of ZSM-5 zeolite and 5% of alumina in the catalyst), the liquid hourly space velocity is 1h -1 . The reaction liquid enters the unsaturated aldehyde distillation tower 2 from the tower kettle. The unsaturated aldehyde distillation column is a packed column with Pall ring packing and 10 equivalent trays. The operating pressure at the top of the tower is 0.1Mpa, the operating temperature at the top of the tower is 99°C, and the discharge temperature at the bottom of the unsaturated aldehyde distillation tower is 164°C. The top material of the unsaturated aldehyde distillation tower 2 enters the aldehyde recovery towe...

Embodiment 3

[0049] Reaction solution hourly space velocity 1.4h -1 , unsaturated aldehyde distillation tower 2 tower top operating pressure 0.12MPa, tower top operating temperature 96 ℃, tower bottom discharge temperature 172 ℃, other process conditions are the same as embodiment 2. The main logistics flow and composition are shown in Table 3.

[0050] Table 3. Main material flow table of solid catalyst catalyzed aldehyde condensation process

[0051]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com