Method for preparing magnetic thin film

A magnetic film and magnetic technology, applied in the direction of magnetic film, the application of magnetic film to substrate, magnetic objects, etc., can solve the problems of limited application of characteristics, and achieve the effect of increasing controllability and rich film forming methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1: According to the patent (200410051573.3), lipophilic magnetic nanoparticles modified with oleic acid were prepared.

[0030] 0.2mol / LFeCl 2 and 0.4mol / LFeCl 3 Mix with concentrated ammonia water, react for 1 hour, add 200 times the amount of water at 10°C, and stir at 10,000 rpm for 2.5 hours; separate the prepared Fe 3 o 4 Nanoparticles, washed twice with pure water, adding pH8.4 aqueous solution under stirring at 40000rpm, then mixing with 2.5 times the calculated amount of sodium oleate under stirring at 40000rpm, heating and reacting at 85°C for 20 minutes, cooling to 25°C, Adjust the pH to 5.2, separate the precipitated magnetic nanoparticles by magnet adsorption method, wash the precipitate once with acidic water with pH 4.2, wash with pure water three times, and then dry to obtain oleic acid-modified lipophilic magnetic nanoparticles.

Embodiment 2

[0031] Example 2: Silica-coated core-shell magnetic nanoparticles were prepared according to the patented technology (200810034073.7).

[0032] 0.2mol / L FeCl 2 and 0.4mol / L FeCl 3 Mix with 2mol / L NaOH, react for 25 minutes, add 100 times the amount of water at 15°C, stir at 10000rpm for 1 hour, the crystallization reaction of the particles is completed; separate the crystal particles by applying a magnetic field through the magnetic adsorption method, and wash with distilled water After cleaning, Fe with a particle size of 2-12nm can be obtained 3 o 4 Nanoparticles. Take 3.5 grams of Fe 3 o 4 Nanoparticles are dispersed in a mixed solvent consisting of 1000ml of isopropanol, 20ml of water, and 40ml of concentrated ammonia water with a concentration of 25% to 28% by mass. At room temperature, 0.6mol / L ethyl orthosilicate is added dropwise at a stirring speed of 800rpm. The ester was reacted for 20 hours, and the black solid was separated with a 0.1T permanent magnet, and th...

Embodiment 3

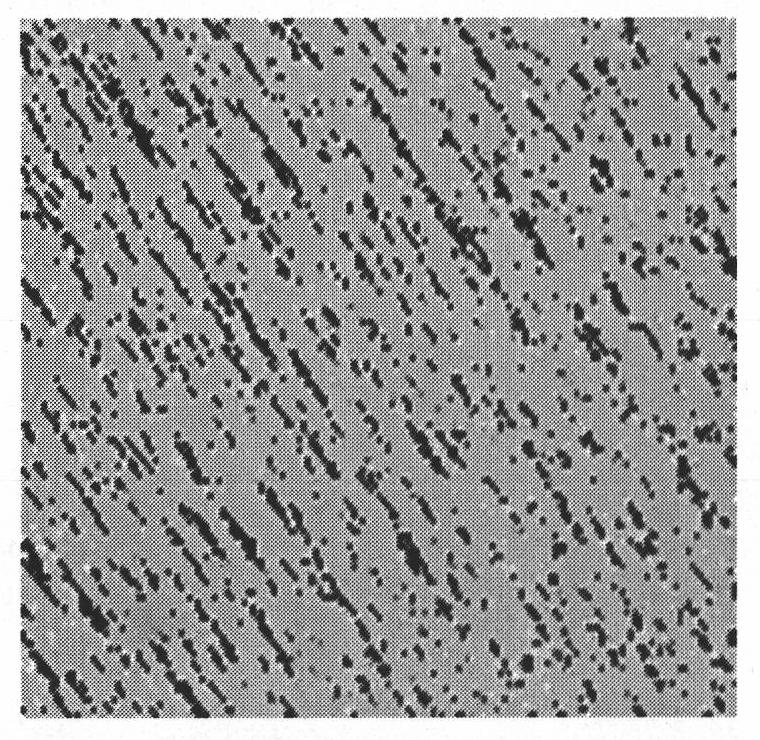

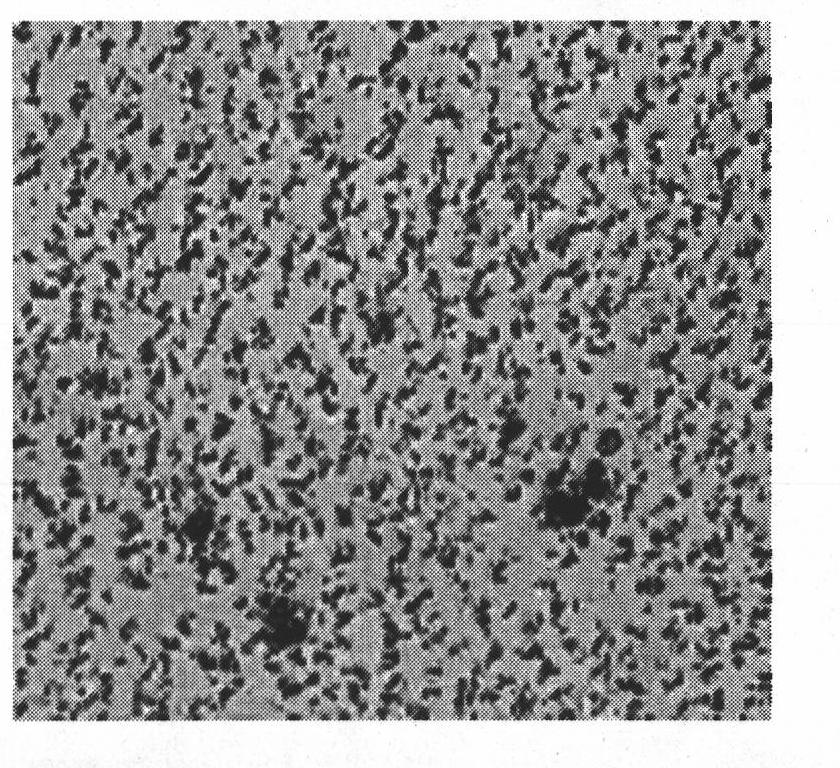

[0033] Embodiment 3: the preparation of magnetic film

[0034] According to the patent (200410051573.3), the lipophilic magnetic nanoparticles modified by oleic acid were obtained (see Example 1)

[0035] Weigh 1g of oleic acid-modified magnetic nanoparticles and disperse them in 10ml of benzene, sonicate for 15min to obtain a benzene dispersion (dispersion A) of 1% (w / v) magnetic nanoparticles; weigh 5g of polystyrene and dissolve in benzene solution In 25ml, 20% (w / v) polystyrene benzene dispersion (dispersion B) was obtained; dispersion A and dispersion B were stirred and mixed to obtain a film-forming precursor, and the film-forming precursor was dropped into a film mold , seal the mold feeding port, place the mold after feeding in the magnetic field of an EM5 electromagnet, the magnetic field air gap is 50mm, the input current is 15A, and the magnetic field induction intensity at the center of the mold is measured to be 0.1T (Tesla); Under the environment, with the volat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic field strength | aaaaa | aaaaa |

| Magnetic field strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com