Magnetic nano-particle immobilized basic protease and preparation method and application thereof

A magnetic nanoparticle, nanoparticle technology, applied in the direction of being fixed on or in an inorganic carrier, chemical industry, climate sustainability, etc., can solve the problems of poor stability, easy leakage of enzymes, inactivation, etc. Fast recycling, good stability, not easy to leak

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The implementation of the preparation of alkaline protease immobilized on magnetic nanoparticles in the present invention will be specifically described below by taking 1 ml of alkaline protease (0.6 U / μl) immobilized on 1 ml of magnetic nanoparticles (3.6 mg / ml) as an example.

[0022] (1) Preparation of FeSO 4 (0.06M) and FeCl 3 (0.1M) mixed solution, adjust the pH value to 1.5 with hydrochloric acid, under argon protection, add 25% ammonia water drop by drop and stir vigorously until the pH rises to 9, continue to feed argon, stir for 0.5h, and then use Magnetic separation of Fe 3 o 4 The granules were washed 5 times with water and 2 times with ethanol, and the finally obtained granules were dispersed in absolute ethanol with a particle concentration of about 3.45mg / ml (0.015M).

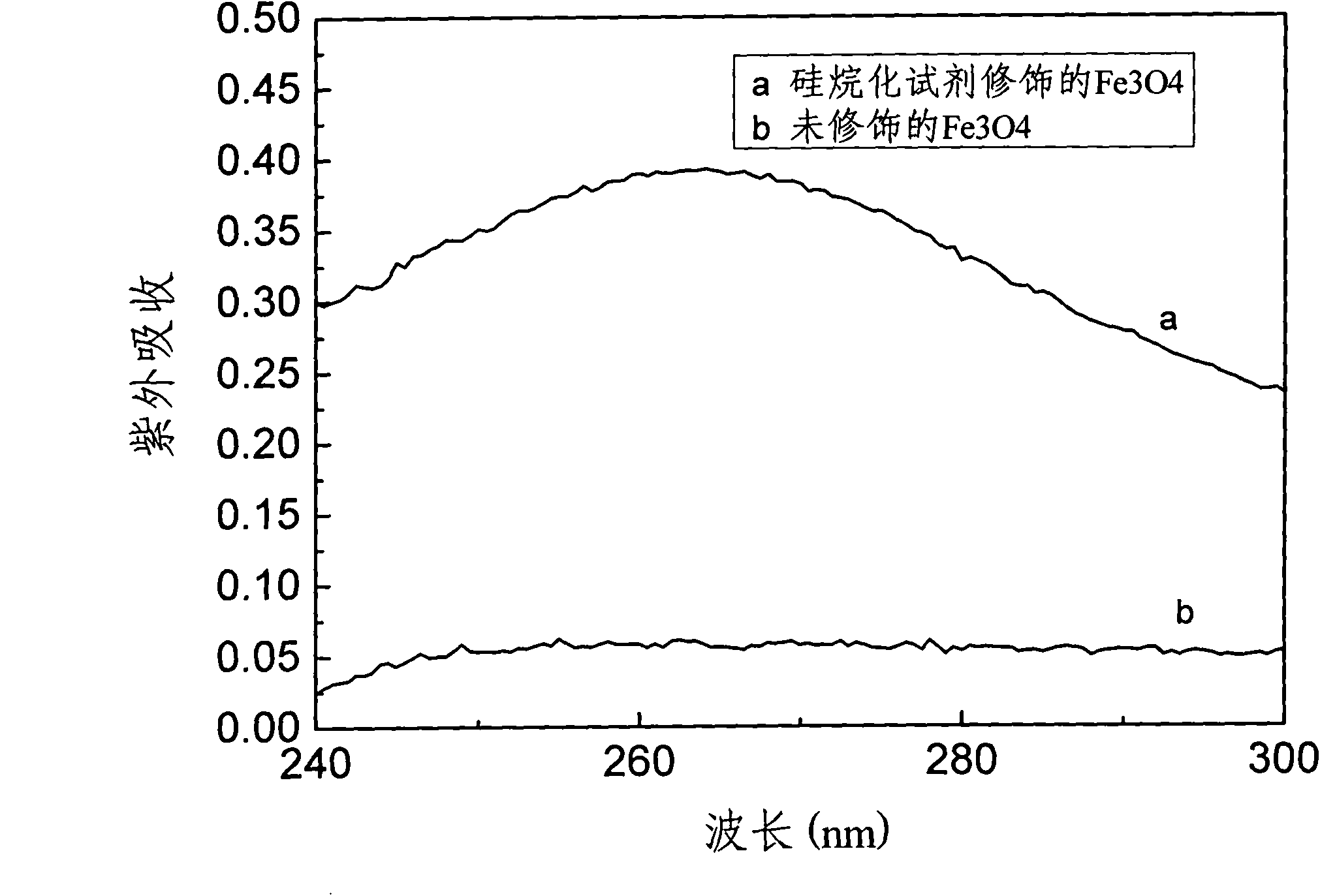

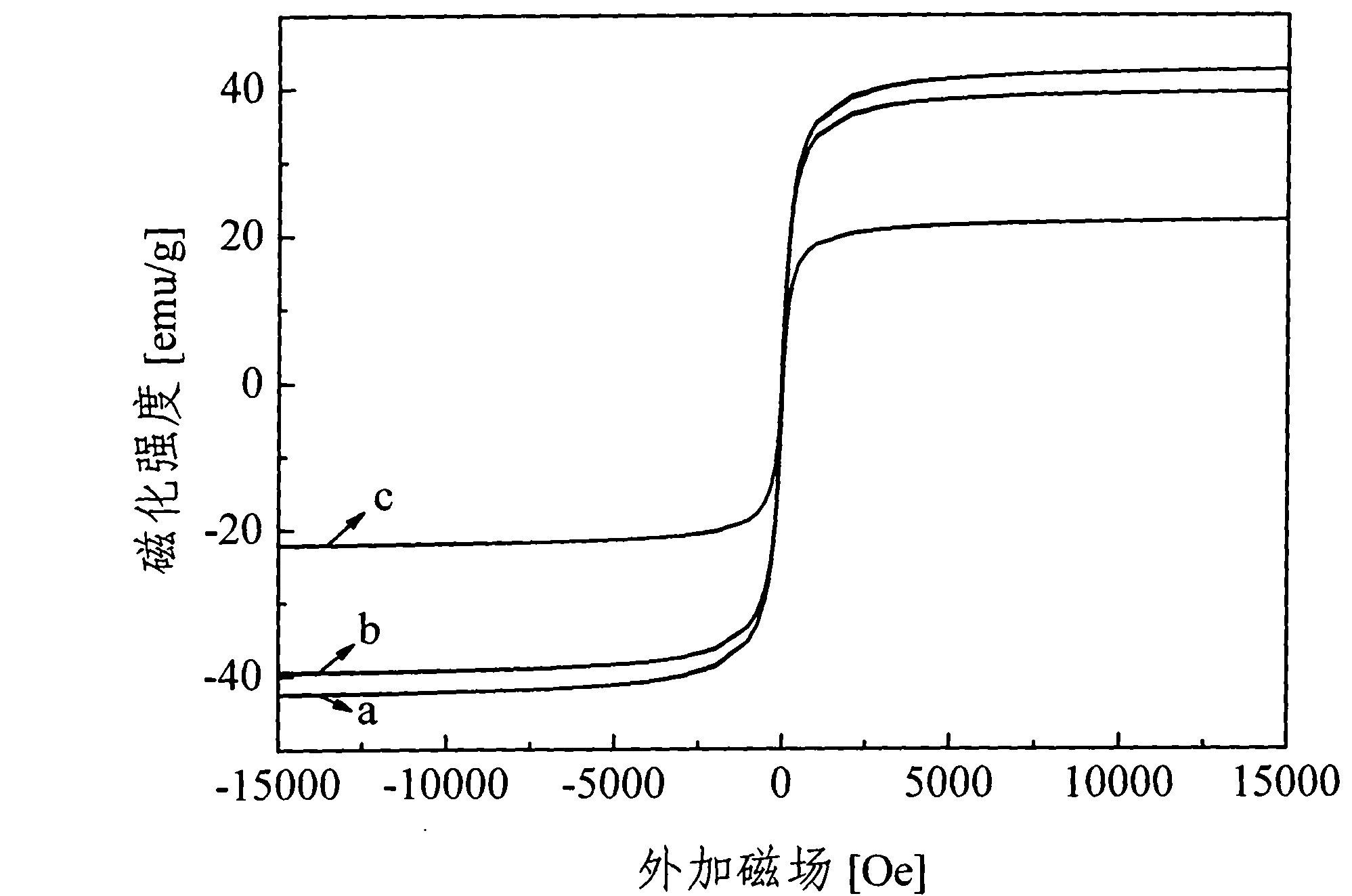

[0023] (2) Take out 25ml of the above-mentioned Fe 3 o 4 Disperse in 50ml of ethanol and 75ml of water, pass through argon to exclude the air, then sonicate for 0.5h, add an appropriat...

Embodiment 2

[0026] The implementation of the application of the magnetic nanoparticle-immobilized alkaline protease in biomass green conversion will be specifically described below by taking the hydrolysis of casein and rapeseed meal catalyzed by the magnetic nanoparticle-immobilized alkaline protease of the present invention as an example.

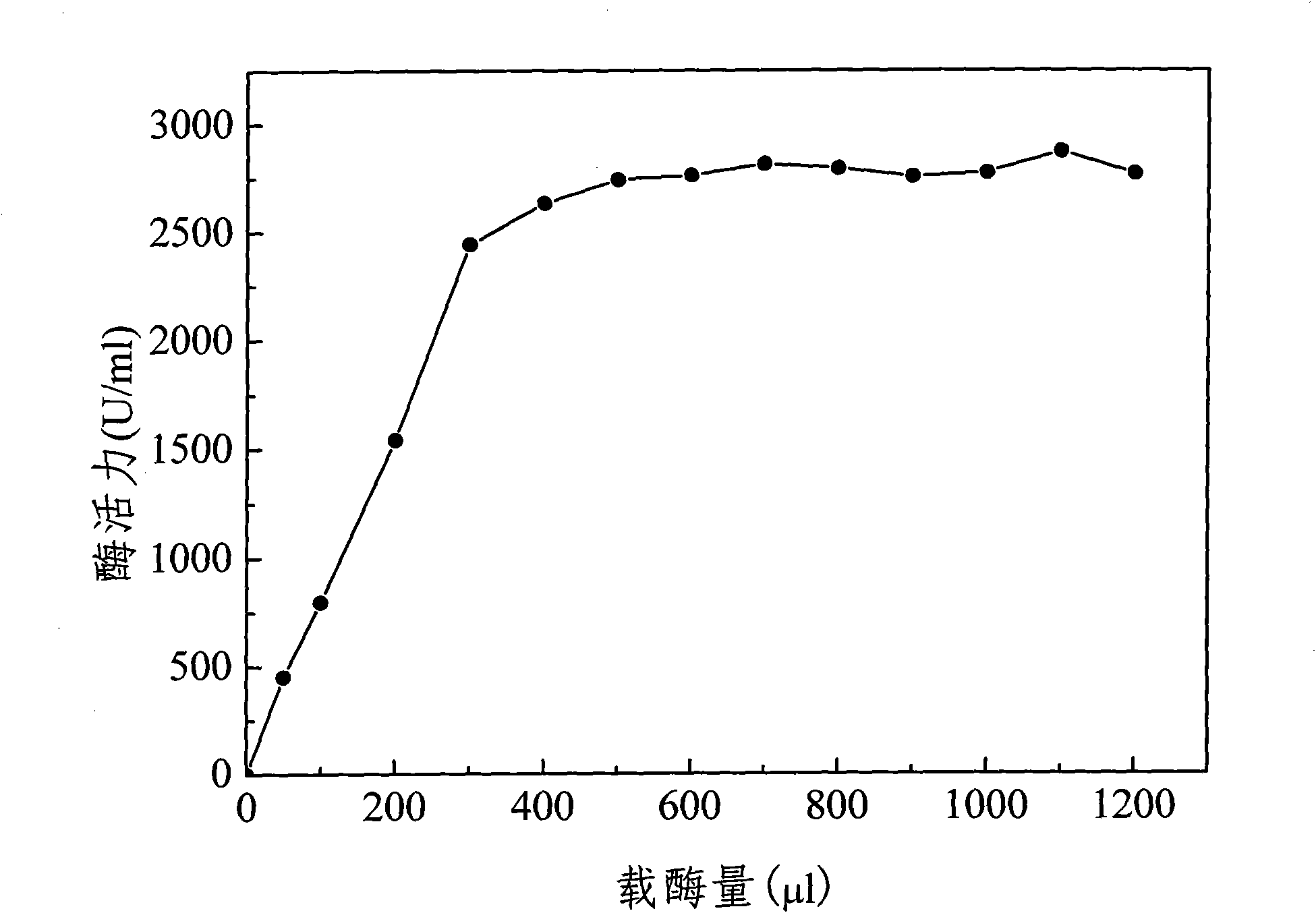

[0027] (1) Detection of the catalytic activity of alkaline protease immobilized on magnetic nanoparticles to casein

[0028] The catalytic activity of alkaline protease immobilized on magnetic nanoparticles was detected by Folin reagent chromogenic method. Take out 1ml of alkaline protease solution immobilized with magnetic nanoparticles, preheat at 40°C for 2min, add 1ml of casein (10mg / ml), react in water bath at 40°C for 10min, add 2ml of trichloroacetic acid (0.4mol / L), mix well, 5000rad Centrifuge for 10min, take out 1ml supernatant, add 5ml Na 2 CO 3solution (0.4mol / L), then add 1ml of Folin’s reagent (diluted twice), develop color in a water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com