Method for preparing organic wastewater treating agent

A technology for organic wastewater treatment and organic solvents, applied in the direction of adsorption water/sewage treatment, chemical instruments and methods, and other chemical processes, which can solve the problems of low activity of hexamethylene diisocyanate and long gel reaction time , to achieve the effect of being beneficial to industrial application, using a short time, and having a good catalytic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

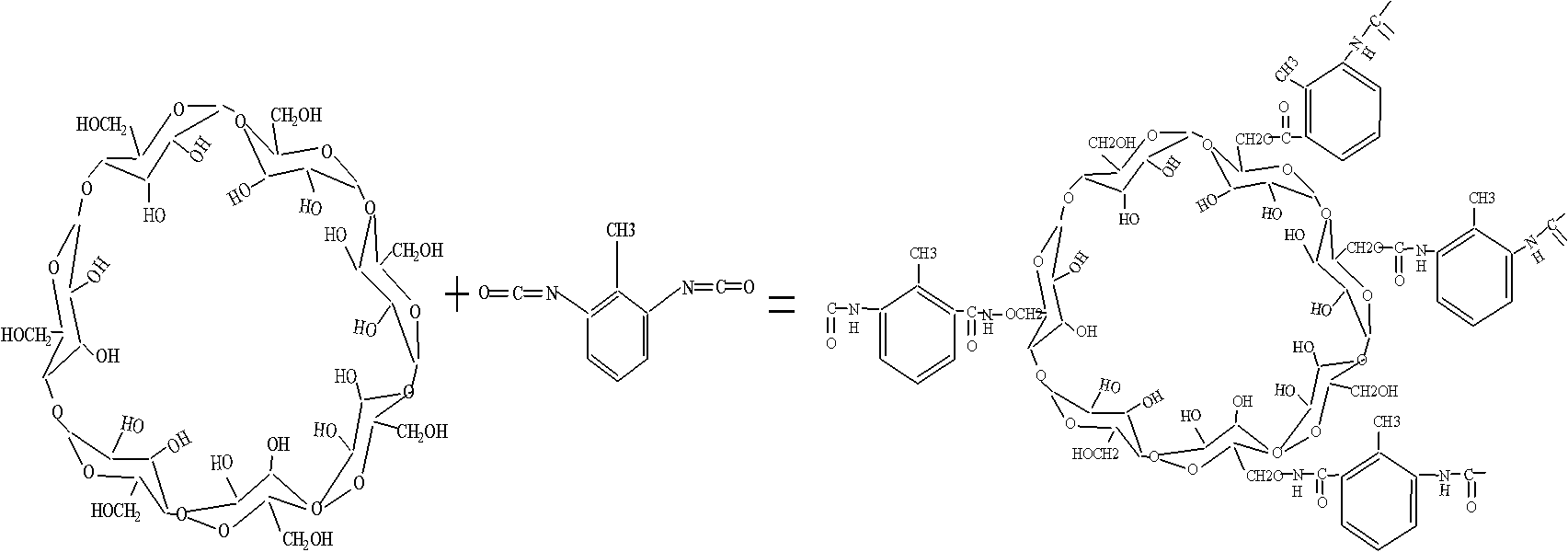

Method used

Image

Examples

Embodiment 1

[0031] Preparation method of adsorbent-cyclodextrin polymer material for treating organic wastewater

[0032] Prepared with nitrogen (N 2 ) tube, condensing tube, stirrer and a four-necked flask with a thermometer, before the test, feed N into the flask. 2 , add the DMF solvent of 15ml after driving the air in the bottle, and drop into 0.04g composite catalyst (dibutyltin dilaurate and triethylenediamine molar ratio is 5). Add 2.69g of β-CD while stirring, add 8ml of DMF solution (containing 2.38g of MDI) dissolved in MDI dropwise at a rate of 1ml / min, react for 40 minutes, and the reaction temperature is 55°C. The response was thorough. Finally, 10 ml of chloroform was added and stirred for 8 hours. The reaction product was washed with a large amount of water (hot water was used to remove β-CD), and dried in vacuum for 24 hours to obtain 4.34 g of the cross-linked product. The primary removal rate of phenolic substances in wastewater is 89%.

Embodiment 2

[0034] Preparation method of adsorbent-cyclodextrin polymer material for treating organic wastewater

[0035] Prepared with nitrogen (N 2 ) tube, condensing tube, stirrer and a four-necked flask with a thermometer, before the test, feed N into the flask. 2 , Add 20ml of DMF solvent after the air in the bottle is driven away, and drop 0.08g of composite catalyst (dibutyltin dilaurate and tributylamine mol ratio is 8). Add 3.89g of β-CD while stirring, add 15ml of DMF solution (7.72gMDI) dissolved in MDI at 0.5ml / min, react for 8 hours, the reaction temperature is 60°C, the purpose is to make the crosslinking reaction complete. Finally, 15 ml of chloroform was added and stirred for 12 hours. The reaction product was washed with a large amount of water (using hot water to remove β-CD), and dried in vacuum for 20 hours to obtain a cross-linked product of 9.88 g. The primary removal rate of phenolic substances in wastewater is 90%.

Embodiment 3

[0037] Preparation method of adsorbent-cyclodextrin polymer material for treating organic wastewater

[0038] Prepared with nitrogen (N 2) tube, condensing tube, stirrer and a four-necked flask with a thermometer, before the test, feed N into the flask. 2 , add the DMF solvent of 27ml after driving the air in the bottle clean, and drop into 0.2g composite catalyst (dibutyltin oxide and triethylamine mol ratio is 8). Add 5.69g of γ-CD while stirring, slowly add 25ml of HDI-dissolved DMF solution (10.33gHDI) at 1.5ml / min, react for 18 hours, and the reaction temperature is 70°C, the purpose is to make the crosslinking reaction complete. Finally, 15 ml of chloroform was added and stirred for 20 h. The reaction product was washed with a large amount of water (using hot water to remove γ-CD), and dried in vacuum for 30 h to obtain 13.68 g of the cross-linked product. The primary removal rate of phenolic substances in wastewater is 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com