Method for preparing efficient nano ferric oxide drinking water type flocculants

A nano iron oxide and flocculant technology, applied in iron oxide/iron hydroxide, nanotechnology and other directions, can solve the problems of easy residual iron ions, high aluminum ion content, secondary pollution of water bodies, etc. The effect of good particle dispersibility and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

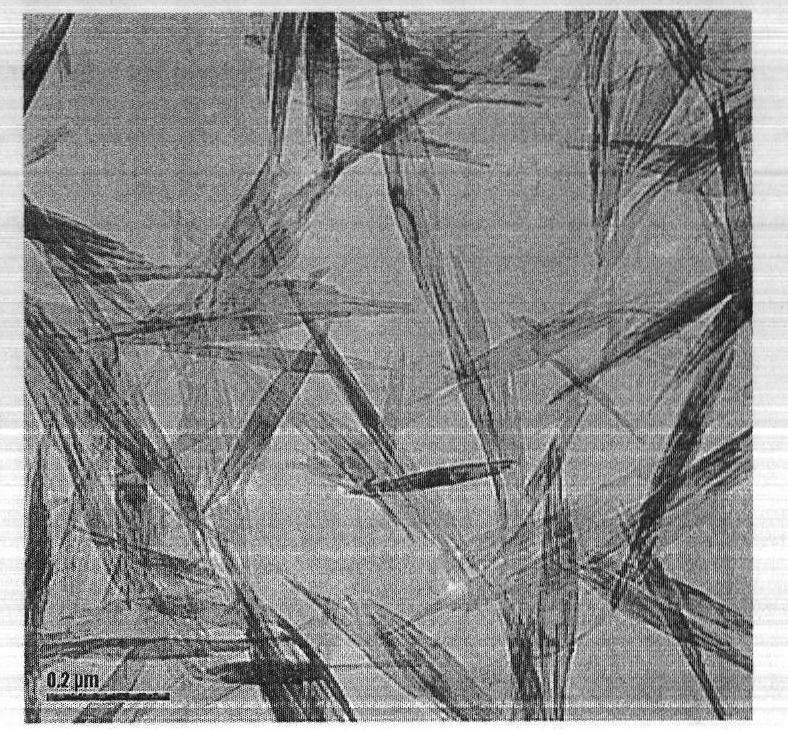

[0027] Take 200ml of FeSO with a concentration of 0.05mol / L 4 The solution was placed in a constant temperature water bath in a four-neck flask at 25°C, and N 2 After driving away the air in the bottle, add 200mL Na with a concentration of 0.05mol / L 2 CO 3 solution, the addition speed is 10mL / min, stir to make it fully mixed, the stirring speed is 3600r / min, and N 2 Switch to air, and the air flow rate is 2L / min to prepare nano-α-FeOOH. The initial stage of the reaction is a nucleation process, during which the pH of the solution is automatically maintained at a constant value of 6-7. When the pH of the system begins to drop, the nucleation process is over and the color of the mixed solution is yellow. After aging the solution containing α-FeOOH seed crystals for 2 h, the crystal growth continued. by dropping Na 2 CO 3 The pH of the solution control system is 4-5. After the reaction is completed, the resulting precipitate is repeatedly washed, heated and dried, and groun...

Embodiment 2

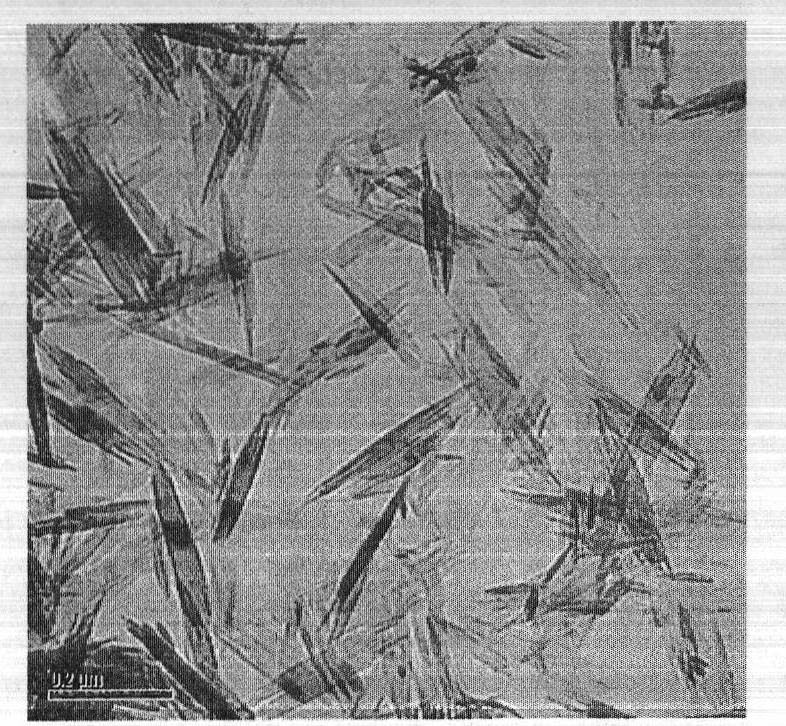

[0029] Take 200ml of FeSO with a concentration of 0.05mol / L 4 The solution was placed in a constant temperature water bath in a four-neck flask at a temperature of 35°C, and N 2 After driving away the air in the bottle, add 200mL Na with a concentration of 0.05mol / L 2 CO 3 solution, the addition speed is 10mL / min, stir to make it fully mixed, the stirring speed is 3600r / min, and N 2Switch to air, and the air flow rate is 2L / min to prepare nano-α-FeOOH. The initial stage of the reaction is a nucleation process, during which the pH of the solution is automatically maintained at a constant value of 6-7. When the pH of the system begins to drop, the nucleation process is over and the color of the mixed solution is yellow. After aging the solution containing α-FeOOH species for 2 hours, the crystal growth continued. by dropping Na 2 CO 3 The pH of the solution control system is 4-5. After the reaction is completed, the resulting precipitate is repeatedly washed, heated and dr...

Embodiment 3

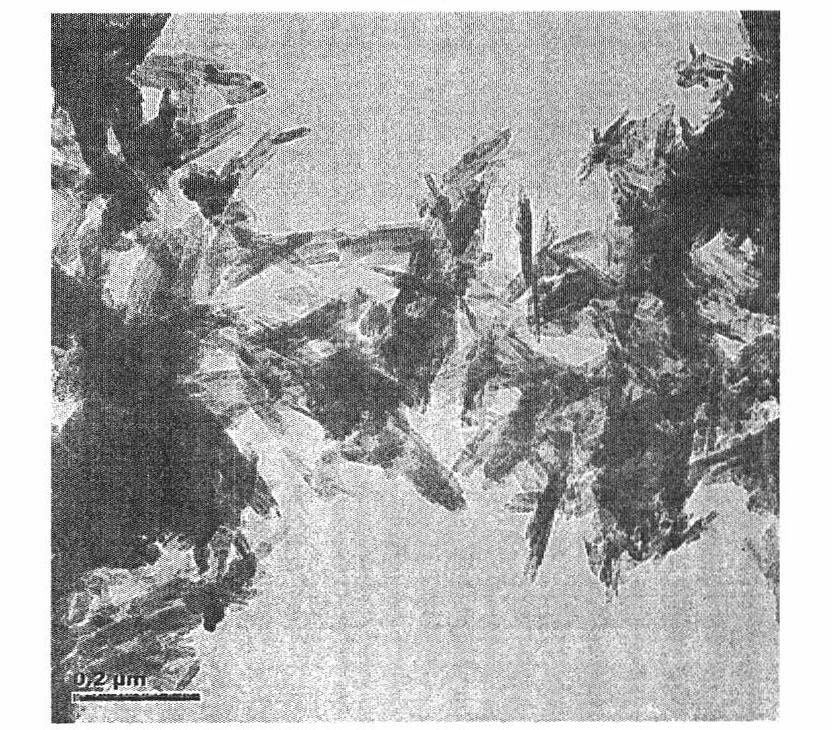

[0031] Take 200ml concentration of 0.05mol / L FeSO 4 solution and Al 2 (SO 4 ) 3 18H 2 O solution, the mixed solution of Al / Fe-0.15 was placed in a constant temperature water bath in a four-necked flask, the temperature was at 35 °C, and N 2 After driving away the air in the bottle, add 200mL Na with a concentration of 0.05mol / L 2 CO 3 Aqueous solution, the addition speed is 10mL / min, stir to make it fully mixed, the stirring speed is 3600r / min, the N 2 Switch to air, and the air flow rate is 2L / min to prepare nano-α-FeOOH. The initial stage of the reaction is a nucleation process, during which the pH of the solution is automatically maintained at a constant value of 6-7. When the pH of the system begins to drop, the nucleation process is over and the color of the mixed solution is yellow. After aging the solution containing α-FeOOH seed crystals for 2 h, the crystal growth continued. by dropping Na 2 CO 3 The pH of the solution control system is 4-5. After the reacti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com