Palladium tin carbon catalyst for meropenem synthesis and preparation method

A technology of carbon catalyst and meropenem, which is applied in the direction of chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc. Activity is not easy to control and other problems, to achieve the effect of inhibiting migration growth, maintaining stability, and improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

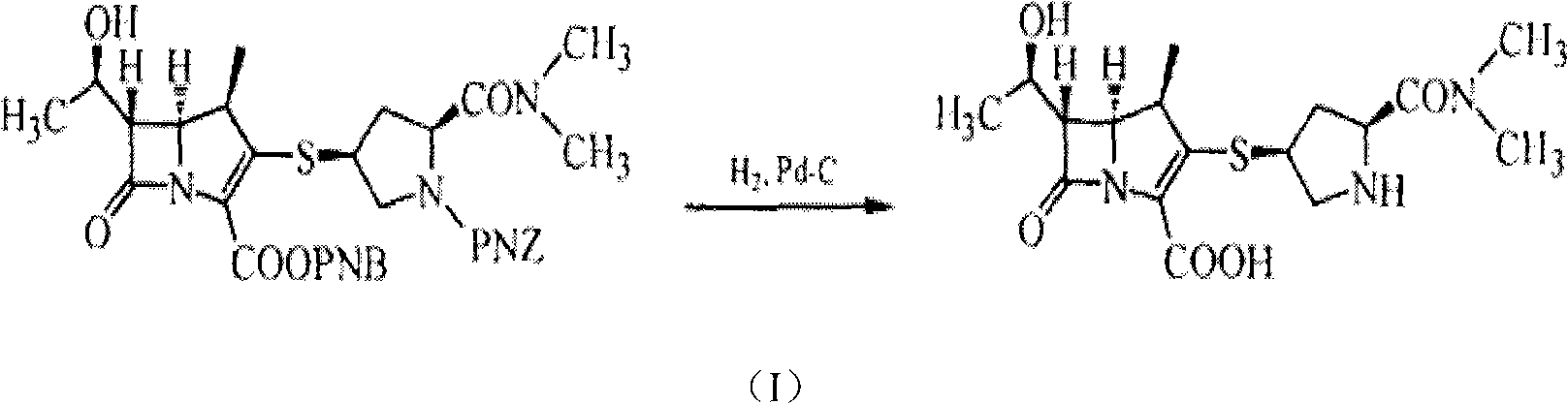

Image

Examples

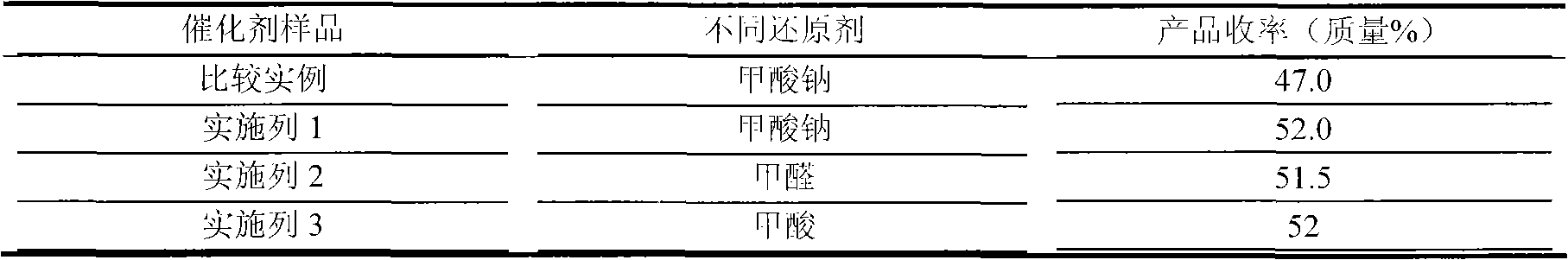

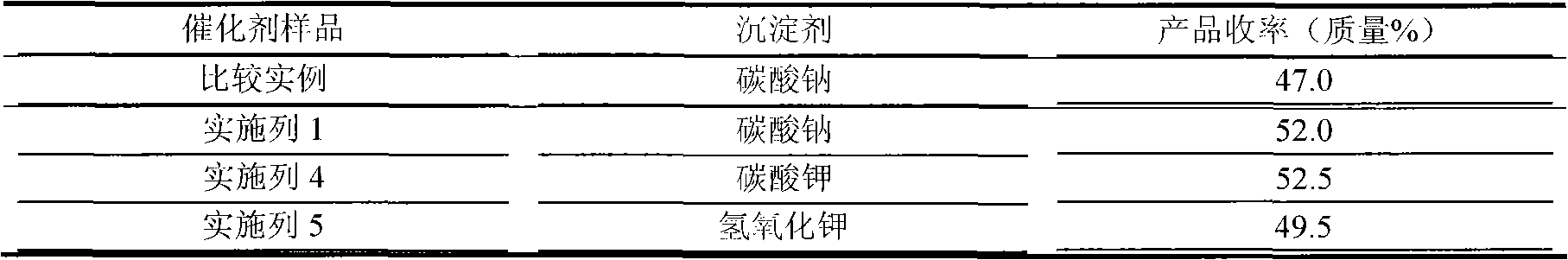

Embodiment 1

[0030] Example 1 (5% Pd / C)

[0031] 1) Accurately weigh 19g of coconut shell charcoal with a particle size of 200-300 mesh. Reflux with 8% boiling phosphoric acid aqueous solution for 2 hours, wash with pure water to pH = 6, then treat with 8% sodium hypochlorite aqueous solution at 30-35°C for 2 hours, and finally wash with pure water until silver nitrate detects that there is no chlorine ion for later use ;

[0032] 2) Accurately weigh 3.13g of potassium chloropalladate, dissolve it in pure water, dilute to 60mL in an ice bath and cool down to 0-5°C, weigh 0.16g of stannous chloride, dissolve in 0.5mL of concentrated hydrochloric acid and dilute to 60mL in an ice bath Cool down to 0-5°C, and quickly pour the stannous chloride solution into the palladium acid solution under stirring conditions;

[0033] 3) 19g of weighed activated carbon is beaten with 300mL of 10% sodium carbonate solution, heated to 55-60°C under stirring conditions and stabilized for 1h;

[0034] 4) Pou...

Embodiment 2

[0036] Example 2 (5% Pd / C)

[0037] 1) Accurately weigh 19g of coconut shell charcoal with a particle size of 200-300 mesh, reflux treatment with 8% boiling phosphoric acid aqueous solution for 2h, wash with pure water to pH=6, and then use 8% sodium hypochlorite aqueous solution at 30-35°C Treat for 2 hours, and finally wash with pure water until there is no chloride ion detected by silver nitrate for later use;

[0038] 2) Accurately weigh 3.13g of potassium chloropalladate, dissolve it in pure water, dilute to 60mL in an ice bath and cool down to 0-5°C, weigh 0.16g of stannous chloride, dissolve in 0.5mL of concentrated hydrochloric acid and dilute to 60mL in an ice bath Cool down to 0-5°C, and quickly pour the stannous chloride solution into the palladium acid solution under stirring conditions;

[0039] 3) 19g of weighed activated carbon is beaten with 300mL of 10% sodium carbonate solution, heated to 55-60°C under stirring conditions and stabilized for 1h;

[0040] 4) Po...

Embodiment 3

[0042] Embodiment 3 (5%Pd / C)

[0043] 1) Accurately weigh 19g of coconut shell charcoal with a particle size of 200-300 mesh. Reflux with 8% boiling phosphoric acid aqueous solution for 2 hours, wash with pure water to pH = 6, then treat with 8% sodium hypochlorite aqueous solution at 30-35°C for 2 hours, and finally wash with pure water until silver nitrate detects that there is no chlorine ion for later use ;

[0044] 2) Accurately weigh 3.13g of potassium chloropalladate, dissolve it in pure water, dilute to 60mL in an ice bath and cool down to 0-5°C, weigh 0.16g of stannous chloride, dissolve in 0.5mL of concentrated hydrochloric acid and dilute to 60mL in an ice bath Cool down to 0-5°C, and quickly pour the stannous chloride solution into the palladium acid solution under stirring conditions;

[0045] 3) 19g of weighed activated carbon is beaten with 300mL of 10% sodium carbonate solution, heated to 55-60°C under stirring conditions and stabilized for 1h;

[0046] 4) P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com