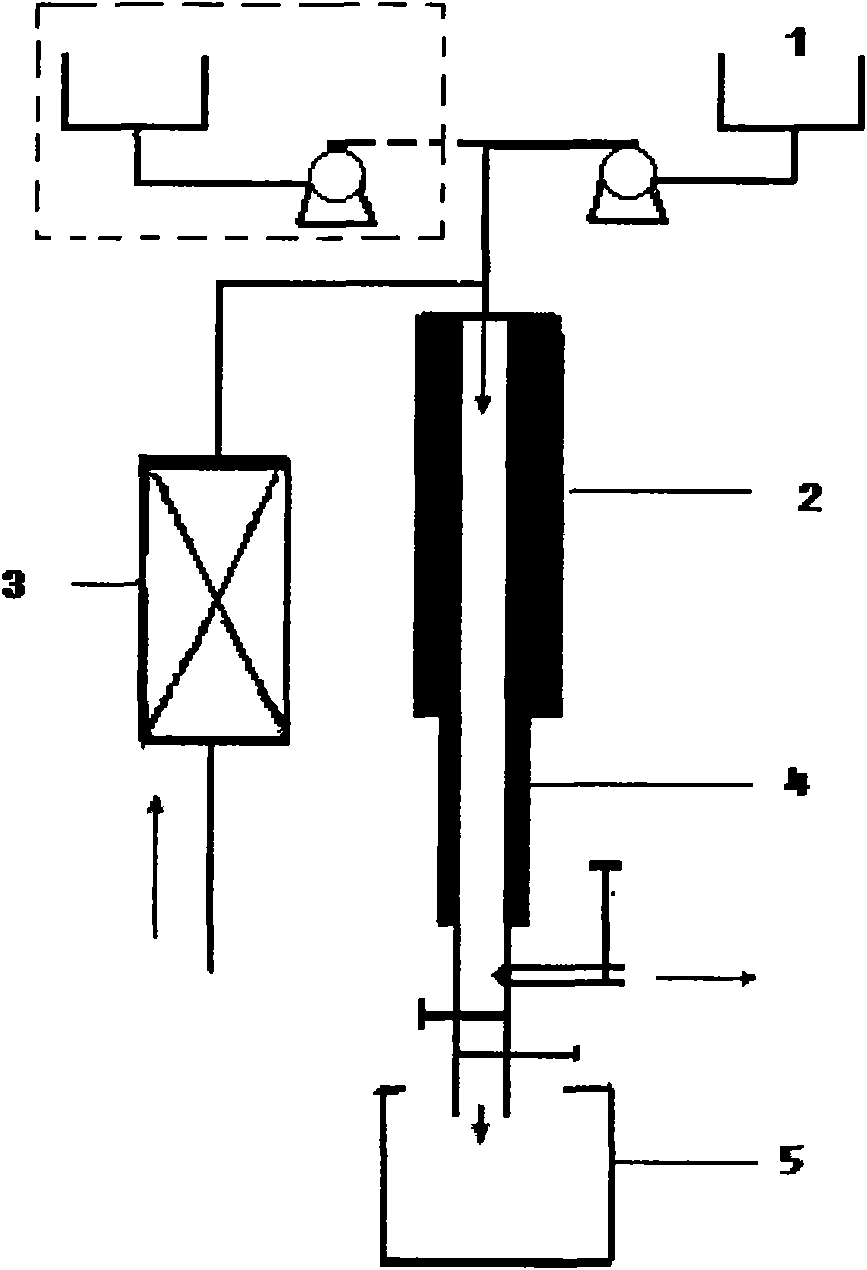

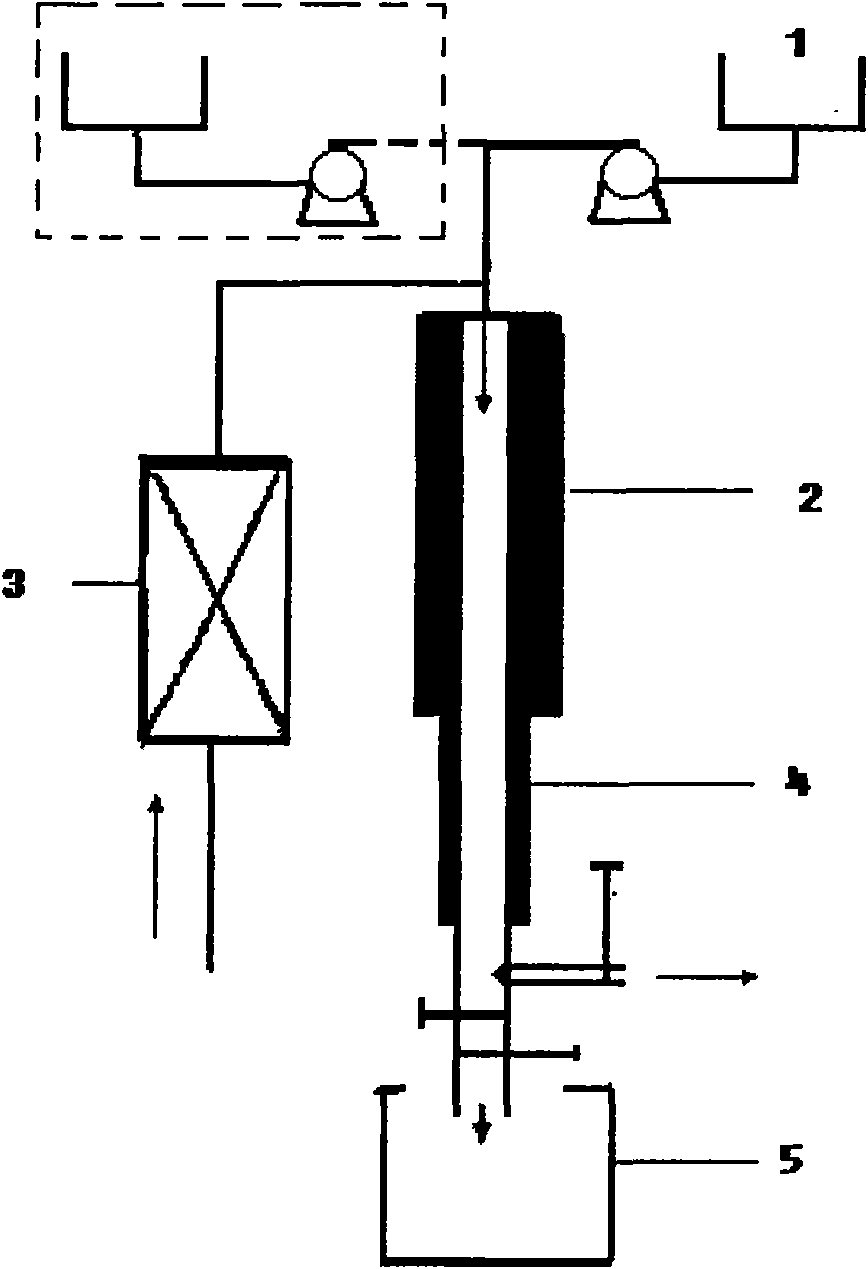

Continuous degradation reaction device for industrial waste water

A degradation reaction and industrial wastewater technology, applied in the direction of heating water/sewage treatment, oxidized water/sewage treatment, etc., can solve the problems of many intermediate links, time-consuming, high treatment costs, etc., and achieve the effect of continuous degradation reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0010] Example 1: Pesticide Paraquat Wastewater Treatment

[0011] The main characteristic pollutants in pesticide paraquat wastewater are: sodium cyanide, sodium chloride, ammonia, ammonium chloride, chloromethylpyridine, pyridine, paraquat cation, synthetic by-products, etc. After pretreatment, influent COD: 20000mg / L. Technological process: Waste water is pumped into the reactor by a high-pressure plunger pump and mixed with high-temperature steam. The reaction temperature is controlled at 560°C, the pressure is 25MPa, the reaction time is 30s, the effluent COD: 68ml / L, and the waste residue is collected in the solid depositor and removed.

example 2

[0012] Example 2: Biochemical pharmaceutical wastewater

[0013] The biochemical drug penicillin fermentation broth is press-filtered and the filtrate is used to extract medicinal ingredients by chemical means, resulting in two types of wastewater: fermentation wastewater and extraction wastewater. Fermentation wastewater contains fermentation residues and microorganisms, etc., and the content of suspended solids is high. Extraction wastewater is the wastewater after the filtrate is extracted with chemical methods. The influent COD: 30000mg / L. This type of wastewater treatment process: the wastewater The high-pressure plunger pump is pumped into the reactor to mix with high-temperature steam, the reaction temperature is controlled at 540°C, the pressure is 23MPa, the reaction time is 1min, the effluent COD: 100ml / L, and the waste residue is collected in the solid depositor and removed.

example 3

[0014] Example 3: Printing and dyeing wastewater

[0015] Dyeing wastewater contains slurry, dyes, auxiliary agents, surfactants, etc., COD=26400mg / L. Technological process: Waste water is pumped into the reactor by a high-pressure plunger pump and mixed with high-temperature steam. The reaction temperature is controlled at 580°C, the pressure is 25MPa, the reaction time is 2min, and the effluent COD: 18ml / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com