Method for preparing graphene-loaded nano alloy catalyst

A nano-alloy and graphene technology, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, etc., can solve the problem of inhomogeneous nanoparticle composition and metal ion reduction rate Inconsistency and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] Step 1. Preparation of graphene oxide (GO):

[0022] Graphite adopts one of natural flake graphite or colloidal graphite, etc., using P 2 O 5 , KMnO 4 , K 2 S 2 O 8 , CrO 3 , HClO 4 , concentrated H 2 SO 4 One or several mixtures in the graphite are pre-oxidized to obtain expanded graphite, and then concentrated H 2 SO 4 and KMnO 4 Strong oxidation is carried out to obtain graphite oxide. For safe operation and proper oxidation degree, the oxidation temperature here is 20~80℃, and the time is 10~12h.

[0023] A large amount of ultrapure water was injected into the mixed solution after the reaction for dilution, an appropriate amount of hydrogen peroxide was added dropwise, and the impurity ions were removed by suction filtration and centrifugation. Under the assistance of ultrasound, the graphite oxide flakes were exfoliated to obtain a brown suspension. In order to achieve effective exfoliation of graphite oxide, the ultrasonic power was 200-300 W and the ...

Embodiment 1

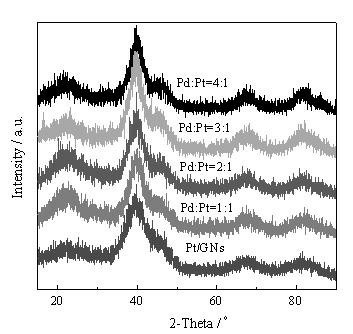

[0031] Embodiment 1. Preparation of graphene-supported Pd-Pt nano-alloy catalyst

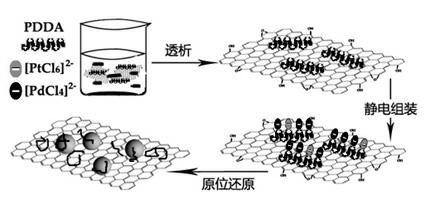

[0032] The synthetic route of graphene-supported Pd-Pt nanoalloy catalyst is as follows figure 1 shown.

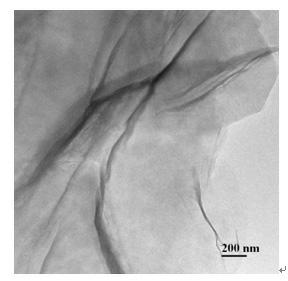

[0033] First, the graphene oxide (GO) aqueous solution was obtained by oxidative exfoliation of flake graphite by a modified Hummers method (W. S. Hummers, R. E. Offeman, J. Am. Chem. Soc. , 1958, 80, 1339.), see appendix figure 2 . The specific operation route is as follows: 1) 80mL concentrated H 2 SO 4 , 11g K 2 S 2 O 8 , 18g P 2 O 5 The mixture was placed in a three-necked flask, heated to 80 °C, and 10 g of dried natural graphite was added. When the reactant completely turned blue-black, the heating was stopped, and the mixture was cooled to room temperature for 6 h. Rinse thoroughly with water, filter the reactant until the filtrate is neutral, and then dry at room temperature to obtain expanded graphite. 2) Under the condition of ice bath, add concentrated H to the ab...

Embodiment 2

[0038] Example 2. Preparation of graphene-supported Pt-Au (3:1) nano-alloy catalyst

[0039] Following the same approach as Example 1, the flake graphite was oxidized and exfoliated to obtain a 10 mg / mL graphene oxide (GO) aqueous solution. To 10 mL of GO aqueous solution, 50 mg of PDDA (MW ≈ 8500) aqueous solution with a concentration of 40% was slowly added dropwise, and the mixed solution was stirred for more than 12 h. The PDDA molecules were electrostatically adsorbed to the GO surface, realizing the functionalization of GO. Then, dialysis (about 48h) was performed, and the ultrapure water was continuously replaced during the dialysis process, and finally a PDDA-GO aqueous solution with a content of about 10 mg / mL was obtained. Measure 5 mL of PDDA-GO aqueous solution and place it in a three-necked flask, and add 20 mL of Na with a total metal mass concentration of 10 mg / mL. 2 PtCl 6 and HAuCl 4 (molar ratio of 3:1) mixed solution. After stirring overnight, the neg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com