Preparation method for wide-side 808nm divided mode semiconductor laser structure

A technology of semiconductors and lasers, which is applied in the field of preparation of discrete-mode semiconductor laser structures, and can solve problems such as complex manufacturing processes, poor stability, and high sensitivity of collimated beams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

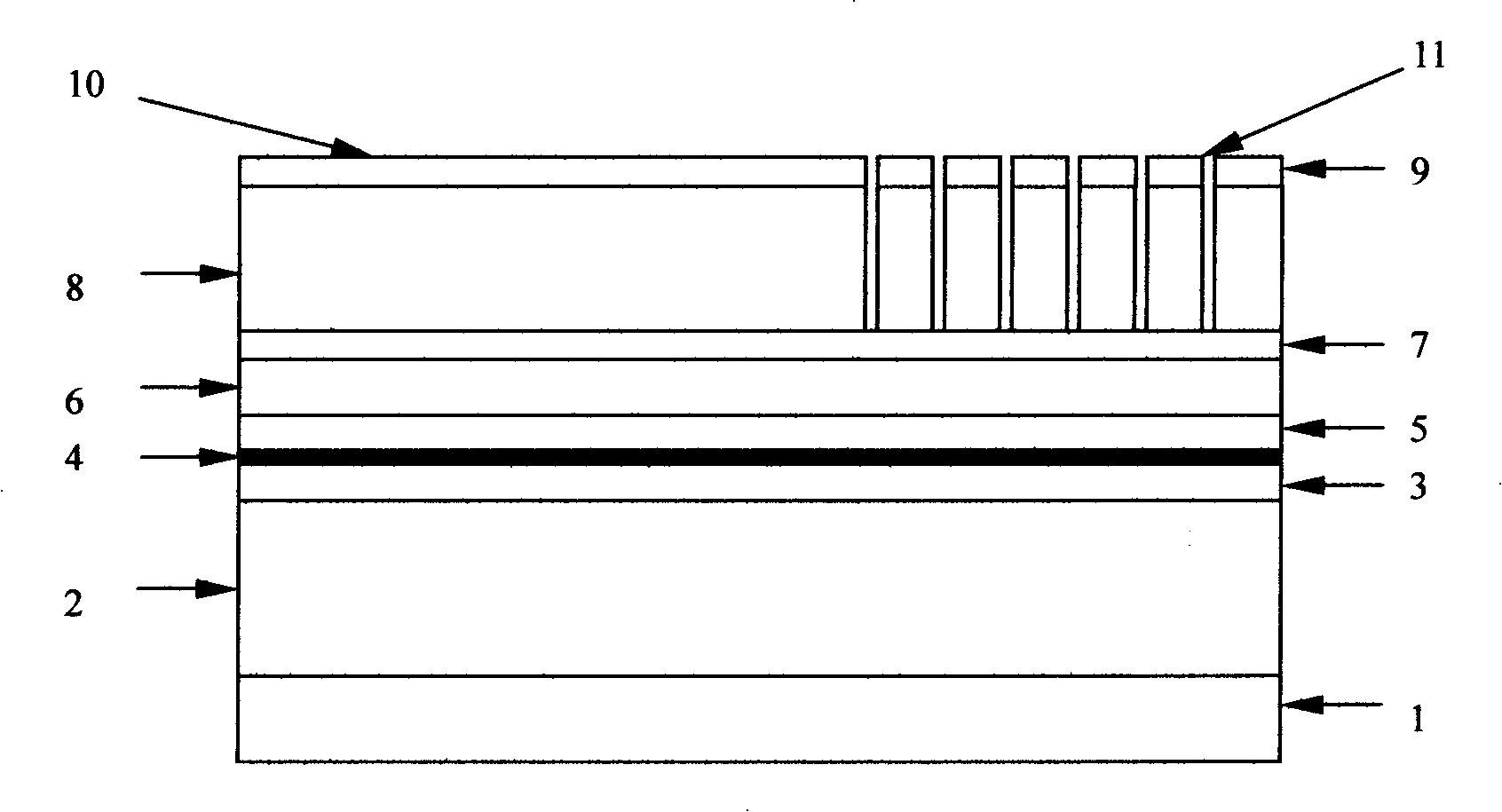

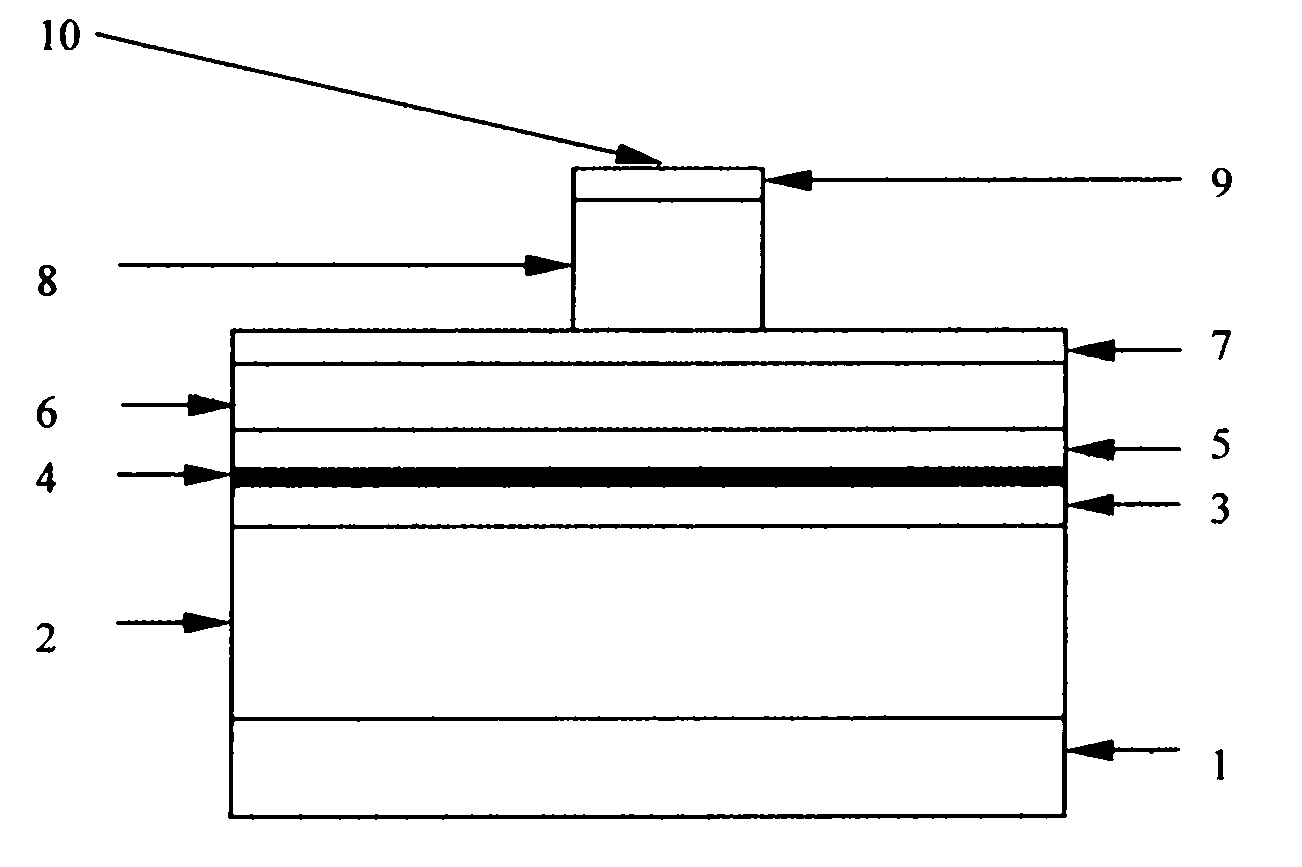

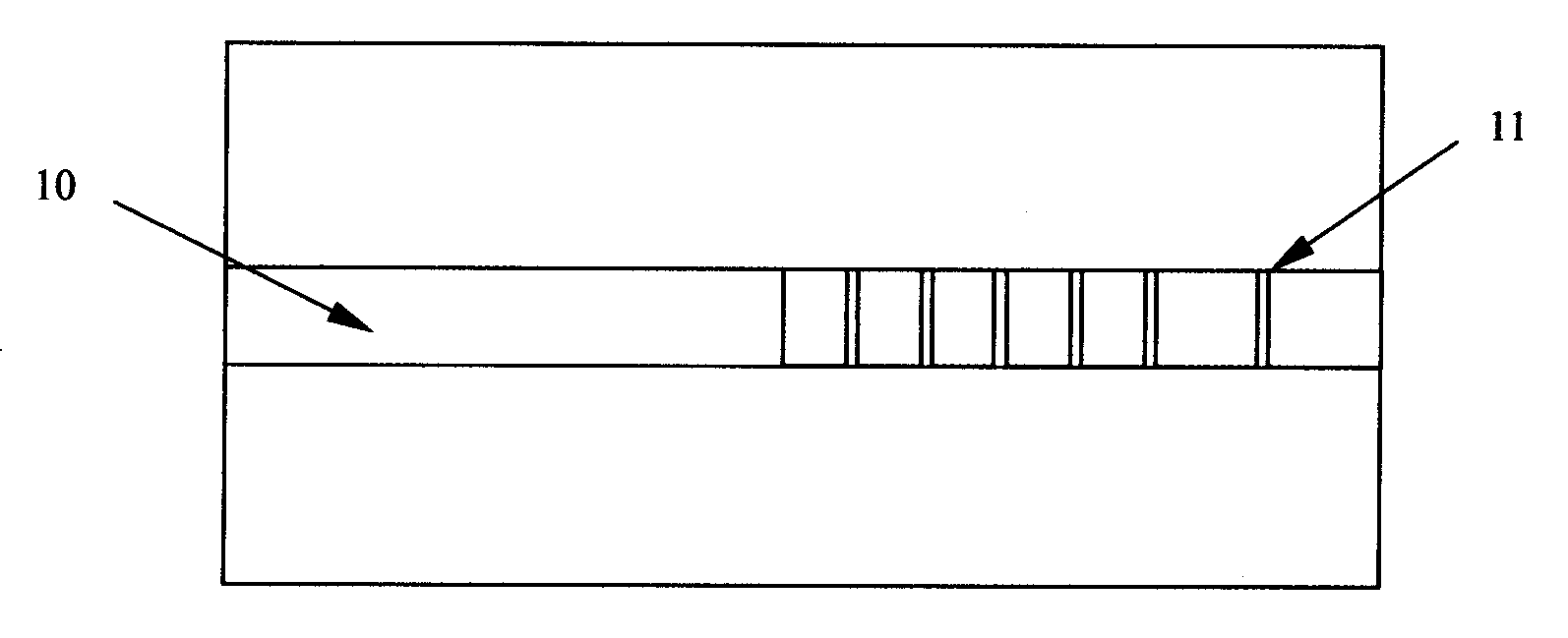

[0025] see figure 1 , figure 2 and image 3 , the invention provides a kind of preparation method of wide-face 808nm discrete mode semiconductor laser, comprises the steps:

[0026] Step 1: Take a GaAs substrate 1;

[0027] Step 2: Prepare N-type AlGaAs lower confinement layer 2, lower waveguide layer 3, quantum well layer 4, upper waveguide layer 5, first P-type upper confinement layer 6, etch cut-off layer on GaAs substrate 1 in sequence 7. The second P-type upper confinement layer 8 and P-type cap layer 9; wherein the lower confinement layer 2 is a highly doped N-type aluminum gallium arsenic material (Al 0.53-0.55 Ga 0.45-0.47 As), the Si doping concentration is 1×10 18 cm -3 , with a thickness of 1.5 μm, the purpose is to limit the diffusion of carriers in the active region, so as to reduce the threshold current and improve efficiency; the lower waveguide layer 3 is made of non-doped aluminum gallium arsenic material (Al 0.33-0.35 Ga 0.65-0.67 As) with a thicknes...

Embodiment

[0031] see again figure 1 , figure 2 and image 3 Shown, the present invention the present invention provides a kind of preparation method of wide-face 808nm discrete mode semiconductor laser, comprises the steps:

[0032] Step 1: Take a GaAs substrate 1;

[0033] Step 2: Prepare N-type AlGaAs lower confinement layer 2, lower waveguide layer 3, quantum well layer 4, upper waveguide layer 5, first P-type upper confinement layer 6, etch cut-off layer on GaAs substrate 1 in sequence 7. The second P-type upper confinement layer 8 and P-type cap layer 9; wherein the lower waveguide layer 3 is made of undoped AlGaAs material, wherein the quantum well layer 4 is made of undoped AlGaInAs material, wherein the upper The waveguide layer 5 is made of non-doped AlGaAs material, wherein the first P-type upper confinement layer 6 is made of highly doped AlGaAs material with a thickness of 0.2 μm, and the etching cut-off layer 7 is highly doped P-type Indium gallium phosphide material w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com