Method for processing beancurd by using cucumber fermentation liquor and transglutaminase composite coagulating agent

A technology of transglutaminase and fermented liquid, which is applied in the field of tofu production, can solve the problems of unstudied mechanism and conditions, unstable quality of finished products, unsuitable for frying, etc., so as to improve technological content, quality and safety sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The preparation of cucumber fermented liquid: select the cucumber that does not have damage by disease and insect color and luster to clean, remove inedible part, cucumber and water are beaten by the ratio of cucumber: water = 1: 1, filter with filter cloth (200 mesh) to remove slag, sterilize (sterilize) The condition is 95°C, 10 minutes), the sterilized cucumber juice is divided into conical flasks, and 10g / L cucumber juice skimmed milk powder and 10g / L cucumber juice glucose are added as culture medium, and lactic acid mixed live bacteria powder is inoculated , the mixed bacteria powder includes five strains of Bifidobacterium, Lactobacillus bulgaricus, Streptococcus thermophilus, Lactobacillus acidophilus, and Lactobacillus casei (place of origin: Denmark, distributed by Beijing Chuanxiu Technology Co., Ltd.), and the inoculum size is 5g / L cucumber juice, inoculate the mixed bacteria powder into cucumber juice, seal it, and incubate at 30°C for 18 hours to obtain a s...

Embodiment 2

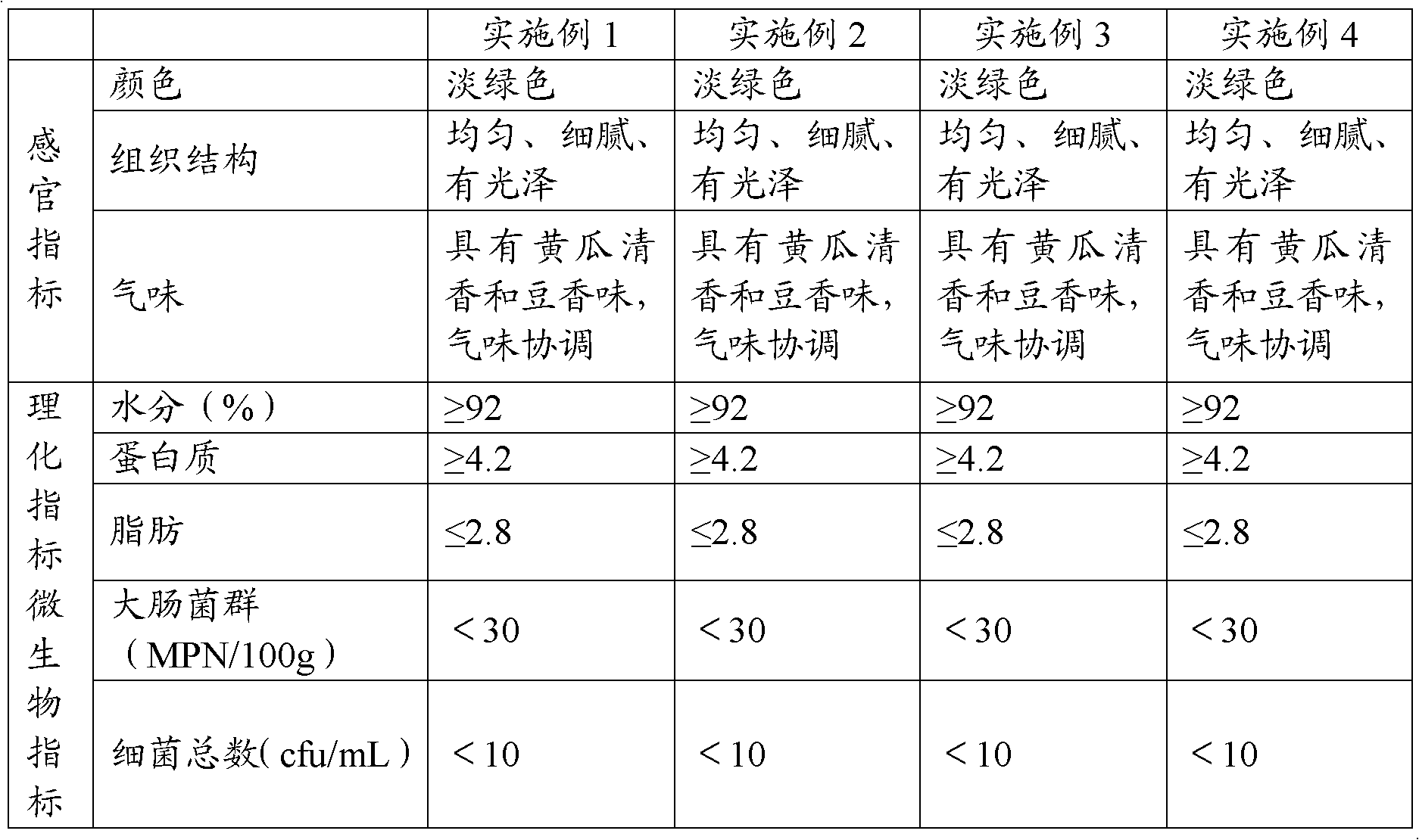

[0022] Dry beans (northeast soybeans) are cleaned, soaked in water at a mass ratio of dry beans: water of 1:3, soaked at a temperature of 30°C, soaked for 8 hours, beaten, filtered with a 120-mesh filter cloth, boiled, and the soybean milk is boiled according to the weight of dry beans Add 0.1% food defoamer (ingredients: glyceryl monostearate, light calcium carbonate, phospholipid), stir to defoam, continue to boil and keep boiling for 5 minutes, filter with 120 mesh filter cloth, cool to 15°C, Stir with a mixer at a stirring speed of 250 rev / min, add the cucumber fermented liquid (preparation method is the same as in Example 1) into the soy milk according to the ratio of cucumber fermented liquid to soy milk 16:100 (volume ratio v / v), mix well and mix with 0.8 Adding amount of g / L soy milk Add transglutaminase into soy milk, subpackage, seal, pack, put in 50°C water bath for 60 minutes, take it out, and cool to shape. The tofu finished product is obtained, and the product qu...

Embodiment 3

[0024] Dry beans (northeast soybeans) are cleaned, soaked according to the mass ratio of dry beans: water 1:3, soaked at 20°C, soaked for 10 hours, beaten, filtered with a 120-mesh filter cloth, boiled, and the soybean milk is boiled according to the weight of 0.1 of the dry beans. % Add food defoamer (ingredients: glyceryl monostearate, light calcium carbonate, phospholipid), stir to defoam, continue to boil and keep boiling for 5 minutes, filter with 120 mesh filter cloth, cool to 15°C, use With the mixer stirring at a stirring speed of 250 rev / min, add the cucumber fermented liquid (preparation method is the same as in Example 1) to the soy milk according to the ratio of cucumber fermented liquid and soybean milk of 16:100 (volume ratio v / v), and mix with 0.8 g Adding amount of / L soy milk Add transglutaminase into soy milk, subpackage, seal, pack, put in 50°C water bath for 60 minutes, take it out, cool and shape. The tofu finished product is obtained, and the product qual...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com