Preparation method of micro-nanometer powder, reinforced micro-reaction device and micro-reaction system

A micro-reaction device, micro-nano technology, applied in the direction of microsphere preparation, microcapsule preparation, chemical/physical/physicochemical process of energy application, etc., can solve the difficulty in the application of microreactors and the difficulty in achieving large throughput , difficult to continue and other problems, to achieve the effect of good product quality stability, uniform appearance, and prevent clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

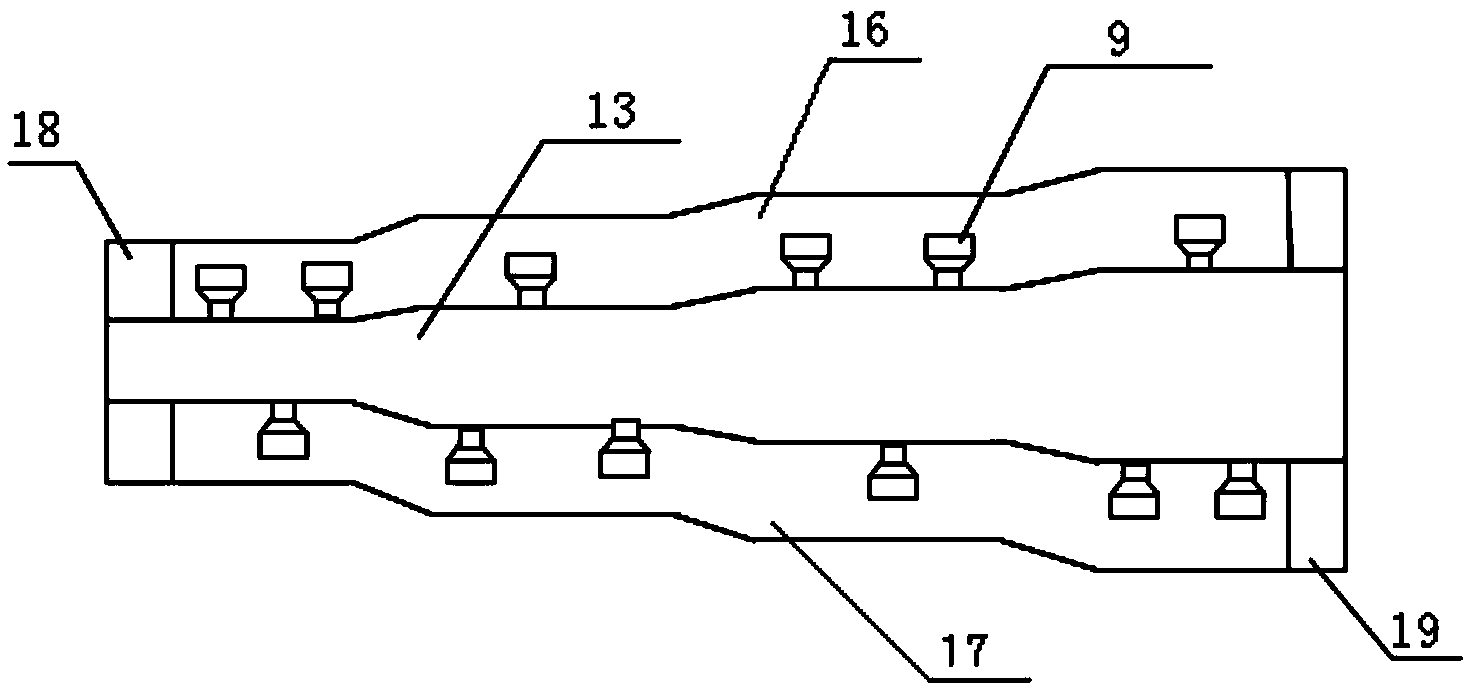

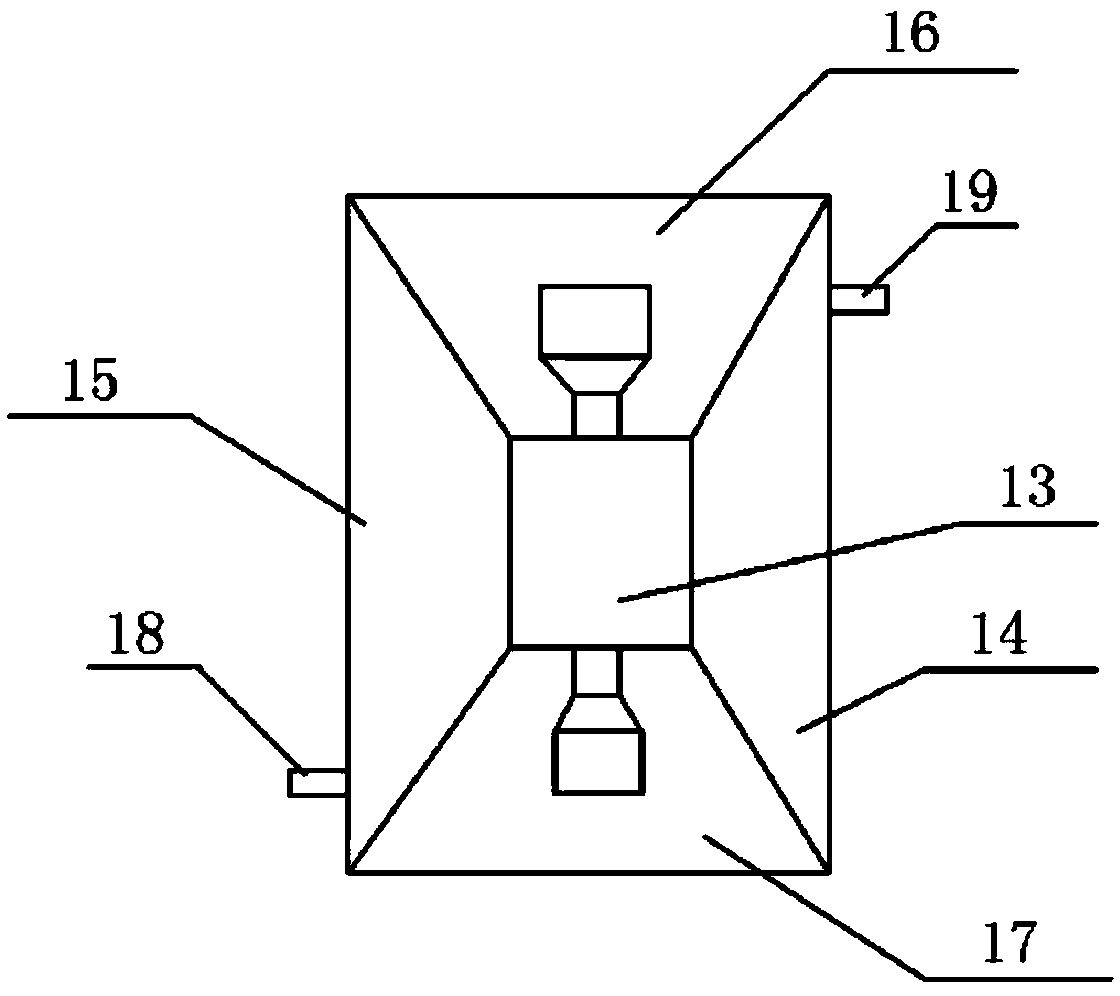

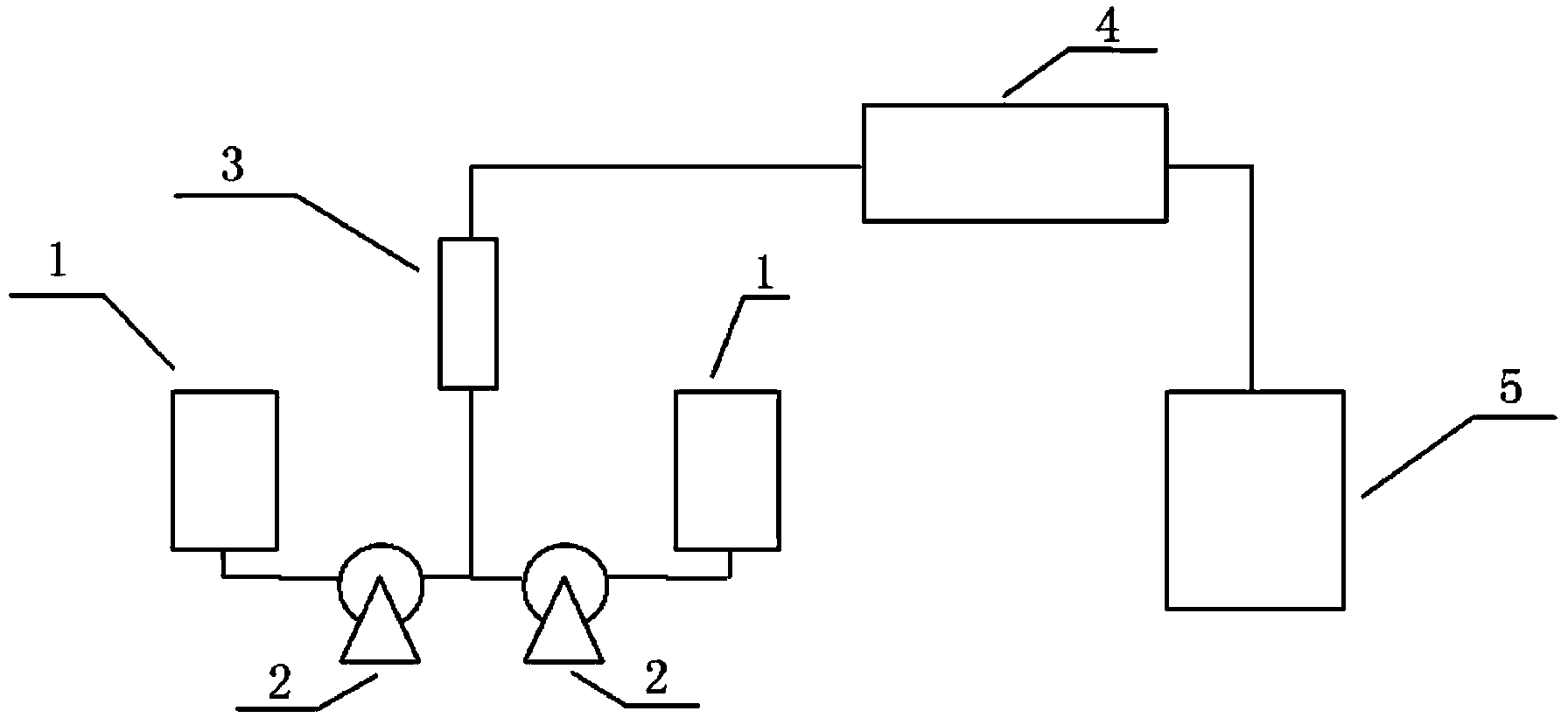

[0037] This example provides an enhanced micro-reaction device for preparing micro-nano powder, which is composed of a pipeline and an ultrasonic generator 9, the pipeline has a central channel 13 with a gradually enlarged size, and the ultrasonic generator 9 is arranged in the central channel 13 external. Further, the pipeline is also provided with a circulating fluid channel, which is located outside the central channel and is provided with a water inlet 18 and a water outlet 19 . The circulating fluid channel is divided into two parts 14 and 15, which are connected to each other and arranged symmetrically outside the central channel for the circulating fluid to pass through. The circulating fluid is water to control the reaction temperature. Furthermore, the pipeline is also provided with a sonotrode installation cavity, and the sonotrode installation cavity is located outside the central channel 13; the sonotrode 9 is installed in the sonotrode installation cavity. The s...

Embodiment 2

[0047] Prepare SiO using the micro-reaction system and method provided in Example 1 2 Microspheres: a. Dissolve the tetraethyl orthosilicate processed through secondary vacuum distillation in absolute ethanol, and configure a solution A with a molar concentration of 0.8mol / L and place it in the storage tank of the feeding device; Yes, dissolve twice-distilled water and analytically pure ammonia water in absolute ethanol to form a solution B with a molar concentration of water of 8 mol / L and a molar concentration of ammonia of 1.6 mol / L and place it in another storage tank of the feeding device Middle; b. Turn on the circulating water system, and pass circulating water at 30°C and 35°C into the micro-mixing device and the enhanced micro-reaction device respectively; at the same time, first turn on the ultrasonic wave of the micro-mixing device, adjust the ultrasonic frequency at 28KHz, and the ultrasonic power at 200W; c. Turn on the two constant flow pumps, pump the equal volu...

Embodiment 3

[0049] Adopt the micro reaction system and method that embodiment one provides to prepare nanometer Fe 3 o 4 : a. Dissolve ferrous iron salt and ferric iron salt in distilled water respectively, and configure Fe 2+ Fe with a molar concentration of 0.3mol / L and 3+ Solution A with a molar concentration of 0.55mol / L is placed in the storage tank of the feeding device; similarly, solution B with a molar concentration of ammonia of 3.0mol / L is placed in the feeding device by dissolving analytically pure ammonia water in distilled water b. Turn on the circulating water system, and pass circulating water at 50°C and 60°C into the micro-mixing device and the enhanced micro-reaction device respectively; at the same time, first turn on the ultrasonic wave of the micro-mixing device and adjust the ultrasonic frequency At 40KHz, the ultrasonic power is 250W; c. Turn on the two constant flow pumps, pump the equal volumes of solutions A and B into the micro-mixing device at the same time,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com