Super capacitor

A supercapacitor and electrolyte technology, applied in capacitors, electrolytic capacitors, circuits, etc., can solve the problems of low capacity density of supercapacitors, and achieve the effects of excellent cycle performance, strong operability and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

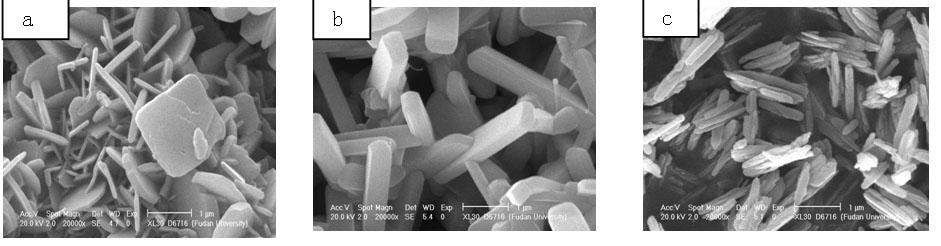

[0022] Weigh a certain amount of elemental molybdenum into a round-bottomed flask, add a certain amount of 30% hydrogen peroxide into the flask under ice-water bath conditions, stir and react to obtain a transparent yellow peroxomolybdic acid sol. Add a polystyrene template with a grain size of 200nm-250nm, adsorb for 1 hour, age overnight, put it into a crucible, and place it in a muffle furnace with 1 o C / min rate heating up to 450 o C, kept for half an hour, cooled to room temperature, and obtained nanosheet MoO 3 (SEM spectra are shown in the attached figure 1 a), The nanosheet size is 1 mm ′1 mm ′ 100 nm.

[0023] Molybdenum trioxide nanosheets were used as the active material of the negative electrode, mixed evenly with 10 wt.% (based on the negative electrode active material) of acetylene black (conductive agent) and 10 wt.% of polytetrafluoroethylene (binder), Pressed on the nickel mesh, as the negative electrode of the supercapacitor; use the nickel mesh as the co...

Embodiment 2

[0026] The polystyrene template is pretreated. The specific treatment method is: take a certain amount of polystyrene powder and disperse it in a PDDA (poly (diallyldimethyl-ammonium chloride) (molecular weight: 100,000, concentration: 2.0 wt.%) solution, soak 30 minutes, centrifuge and set aside.

[0027] Molybdenum trioxide is prepared according to the same method in Example 1, and the obtained molybdenum trioxide is a nanorod structure (scanning electron microscope collection is shown in the attached figure 1 b), the size of the nanostructure unit is 200 nm ′ 200 nm ′ 2 mm.

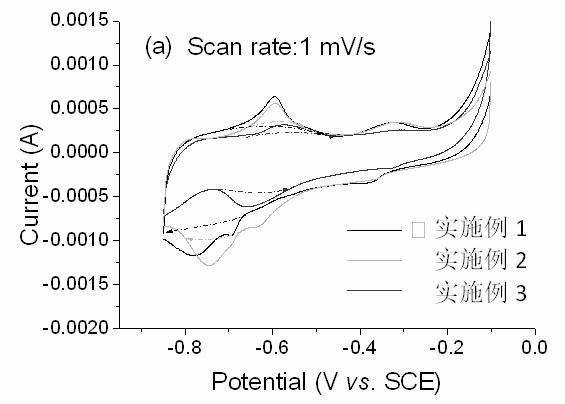

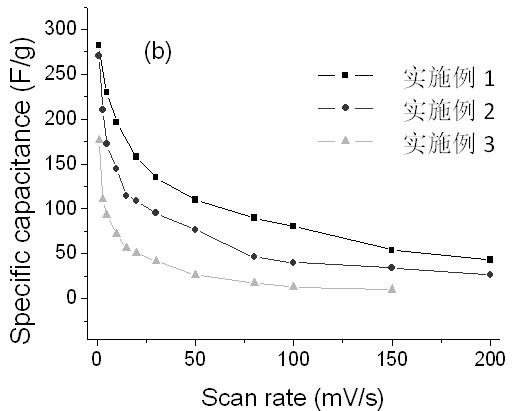

[0028] According to the same method in Example 1, the electrochemical performance test is carried out, and the cyclic voltammetry curve obtained under the scan rate of 1mV / s and the specific capacity under different scan rates are shown in the attached figure 2 and image 3 .

Embodiment 3

[0030] Weigh a certain amount of elemental molybdenum into a round-bottomed flask, add a certain amount of 30% hydrogen peroxide into the flask under ice-water bath conditions, stir and react to obtain a transparent yellow peroxomolybdic acid sol. Aging overnight, put into the crucible, as for the muffle furnace, with 1 o C / min rate heating up to 450 o C, kept for half an hour, cooled to room temperature, and obtained MoO with a spin-cone shape of 1 mm in size 3 (SEM spectra are shown in the attached figure 1 c). According to the same method in Example 1, the electrochemical performance test is carried out, and the obtained cyclic voltammetry curve and the specific capacity under different scanning speeds are also shown in the attached figure 2 and image 3 , test its energy density at different current densities, and calculate its power density, the results are shown in Figure 6 . The energy density was 31 Wh / kg at a power density of 421 W / kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com