High-activity silver chloride convex crystal and preparation method thereof

A silver chloride, high-activity technology, applied in chemical instruments and methods, silver halide, chemical/physical processes, etc., can solve the problems of complex preparation methods of silver chloride, achieve simple synthesis methods and experimental steps, strong absorption, The effect of producing high yields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

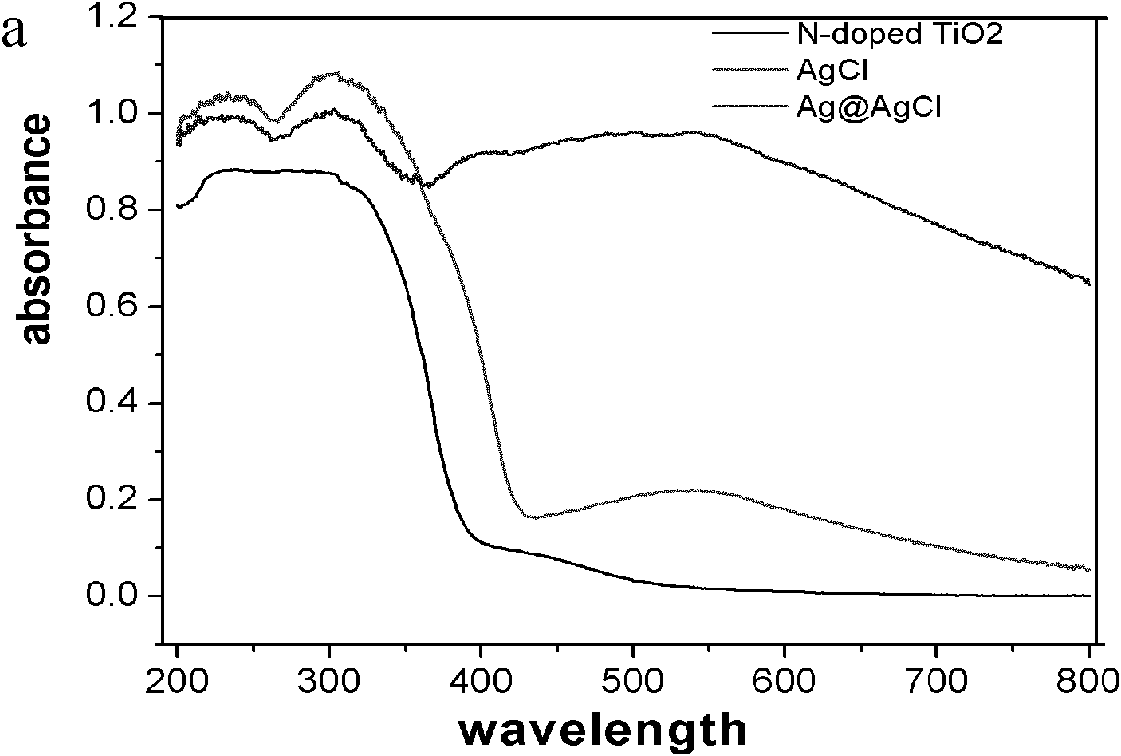

[0029] Measure 90ml deionized water and add it to the beaker, weigh 0.4g ionic liquid (C 16 MimCl) was added to the above-mentioned solution, and the ionic liquid was fully dissolved in water by constant stirring to form a homogeneous solution, and then 10ml of the solution containing 0.4g silver nitrate was quickly injected into the above-mentioned solution, and the constant stirring was used to make the uniform milky white solution. Put the mixture into a 120ml autoclave with a polytetrafluoroethylene liner, react at 160°C for 4 hours, cool to room temperature naturally, separate the sample by centrifugation, and wash the sample with deionized water and absolute ethanol respectively 3 After drying for 24 hours, the product silver chloride convex crystals were obtained. Take 0.2g of silver chloride curved surface crystal and put it into 100ml of deionized water, stir continuously for 1h under the irradiation of 500W xenon lamp, then filter, wash and dry in a vacuum box to for...

Embodiment 2

[0033] Measure 50ml of deionized water into the beaker, weigh 1g of ionic liquid (C 16 MimCl) was added to the above solution, stirring continuously to fully dissolve the ionic liquid, then measuring 10 ml of a solution containing 0.4 silver nitrate and injecting it into the above solution rapidly, stirring continuously to make the solution uniform. The mixture was put into a 100ml autoclave with a polytetrafluoroethylene liner, reacted at 160°C for 4 hours, cooled naturally to room temperature, centrifuged to separate the sample, and washed the sample 3 times with deionized water and absolute ethanol respectively, Vacuum dry for 24 hours.

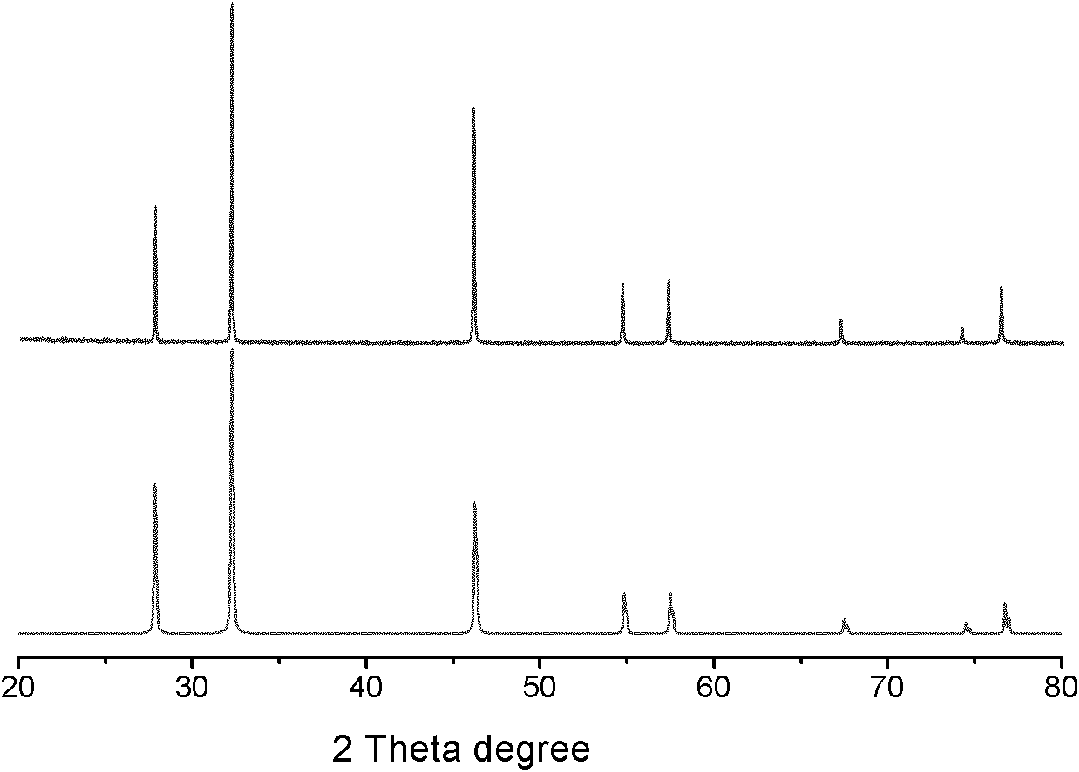

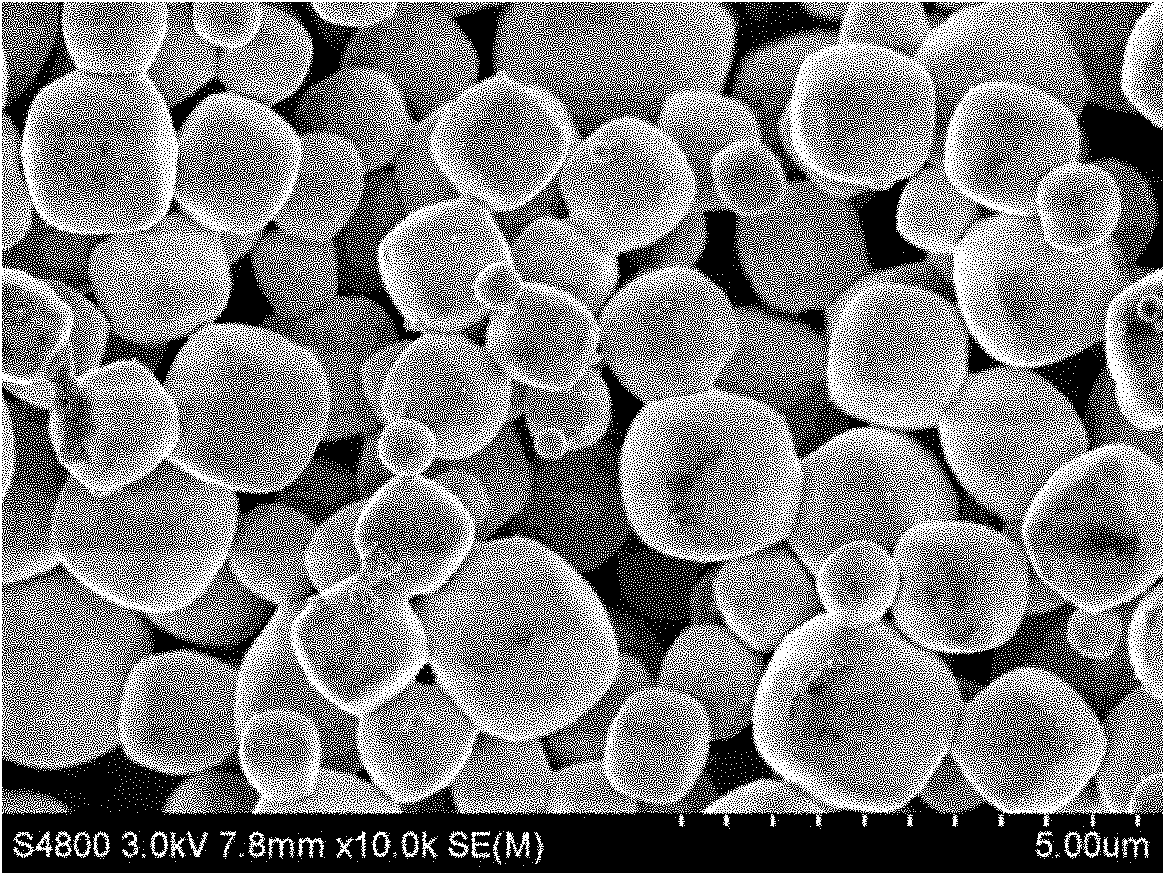

[0034] attached Figure 4 It is the X-ray diffraction figure of this implementation gained product, know by figure, this product is the silver chloride crystal of pure cubic phase. attached Figure 5 Be the SEM picture of the product of this embodiment, by Figure 5 It can be seen that the size of said convex crystals of silver chlorid...

Embodiment 3

[0036] Measure 100ml deionized water into the beaker, weigh 0.4g ionic liquid (C 16 MimCl) was added to the above solution, stirring constantly to fully dissolve the ionic liquid, then weighing 0.4g of silver nitrate to dissolve in the above solution, stirring constantly to make the solution uniform. Put the mixture into a 120ml autoclave with a polytetrafluoroethylene liner, react at 140°C for 8h, cool down to room temperature naturally, separate the sample by centrifugation, and wash the sample 3 times with deionized water and absolute ethanol respectively , vacuum dried for 24h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com