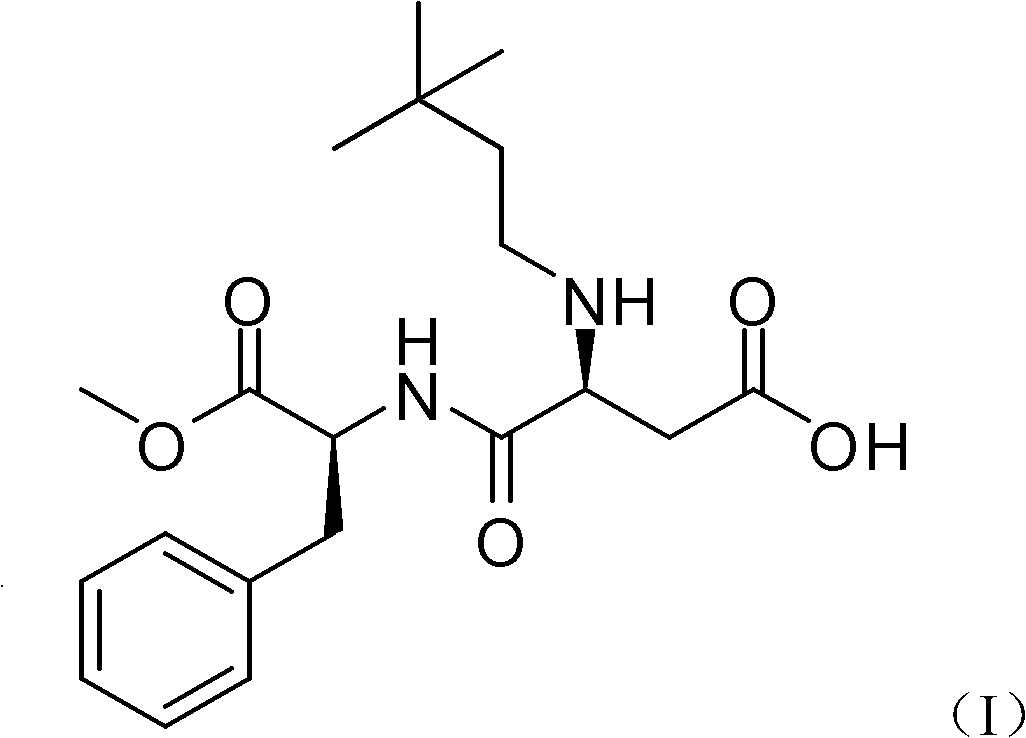

Method for preparing neotame

A neotame and solvent technology, applied in the field of chemistry, can solve problems such as unfavorable industrialized production, complex process operation, low yield and the like, and achieve the effects of being beneficial to environmental protection, reducing environmental pollution and high economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

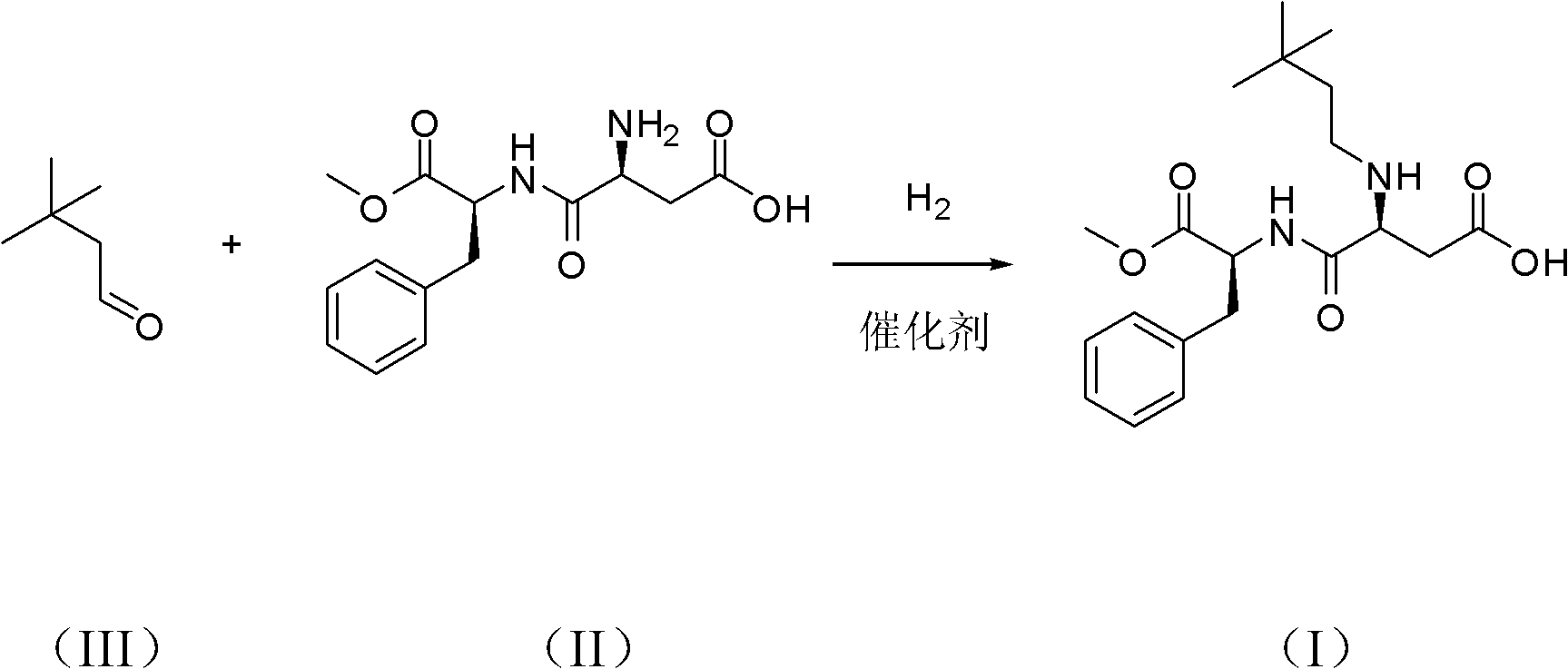

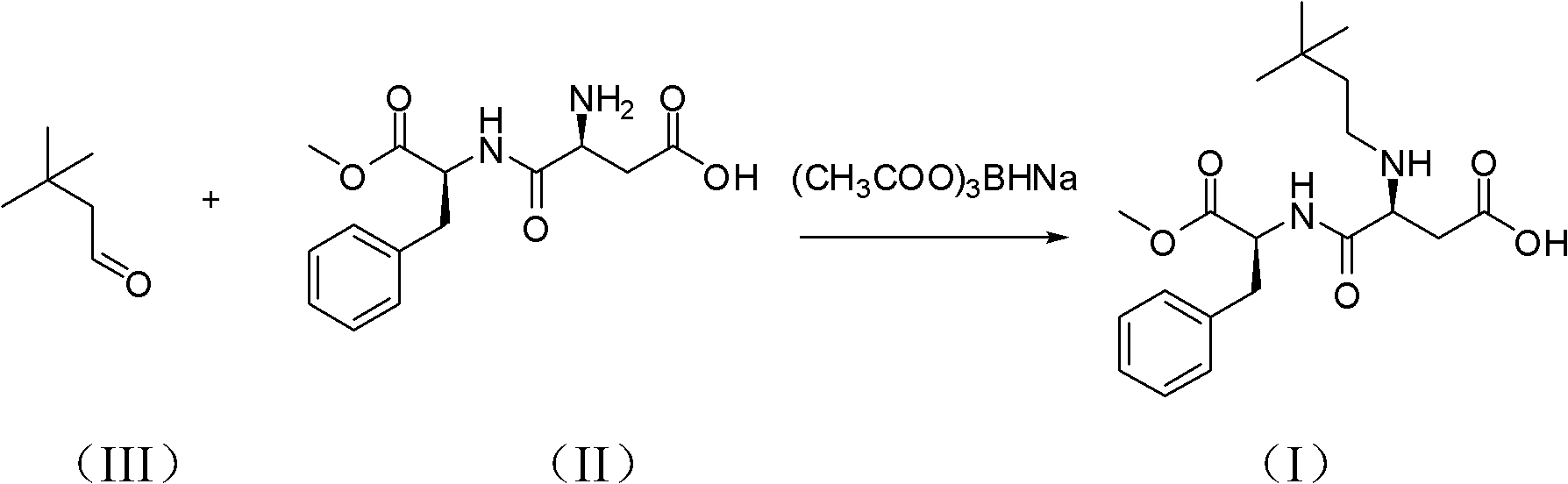

Method used

Image

Examples

Embodiment 1

[0030] Embodiment one kind of preparation method of neotame, contains following preparation steps:

[0031] (1). Add 10g of aspartame to 100ml of methanol, add 3,3-dimethylbutyraldehyde, and react at a temperature of 50°C for 3 hours;

[0032] (2). Add sodium acetate borohydride to the above reaction solution, and react at a temperature of 50°C for 2 hours;

[0033] (3). The above reaction solution was extracted with water and ethyl acetate at a volume ratio of 4:6, and the organic layer was dried;

[0034] (4). The dried product obtained above was crystallized with water and ethanol at a volume ratio of 3:7 to obtain 11.3 g of neotame.

[0035] In this example, neotame yield was 88%.

[0036] The neotame prepared in this example has a purity of 98.9% as measured by high performance liquid chromatography (HPLC) according to the US Pharmacopoeia 33rd edition.

Embodiment 2

[0037] Embodiment two a kind of preparation method of neotame, contains following preparation steps:

[0038] (1). Add 15g of aspartame to 100ml of tetrahydrofuran, add 3,3-dimethylbutyraldehyde, and react at 30°C for 2 hours;

[0039] (2). Add sodium acetate borohydride to the above reaction solution, and react at a temperature of 30°C for 3 hours;

[0040] (3). The above reaction solution was extracted with water and dichloromethane at a volume ratio of 5:5, and the organic layer was dried;

[0041] (4). The dried product obtained above was crystallized with water and acetone at a volume ratio of 5:5 to obtain 17.2 g of neotame.

[0042] In this example, the yield of neotame was 89%, and the purity by HPLC was 98.5%.

Embodiment 3

[0043] Embodiment three a kind of preparation method of neotame, contains following preparation steps:

[0044] (1). Add 12g of aspartame to 100ml of tetrahydrofuran, add 3,3-dimethylbutyraldehyde, and react at 60°C for 2 hours;

[0045] (2). Add sodium acetate borohydride to the above reaction solution, and react at 60°C for 1 hour;

[0046] (3). The above reaction solution was extracted with water and dichloromethane at a volume ratio of 5:5, and the organic layer was dried;

[0047] (4). The dried product obtained above was crystallized with water and acetone at a volume ratio of 4:6 to obtain 13.4 g of neotame.

[0048] In this example, the yield of neotame was 87%, and the purity by HPLC was 99.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com