Corrosion inhibitor for sour oil and gas fields

A corrosion inhibitor, oil and gas field technology, applied in the field of metal anti-corrosion, can solve the problems of corrosion inhibitor environmental protection, poor stability and adaptability, etc., achieve excellent slow-release effect, prevent oxidation, and reduce environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

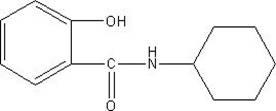

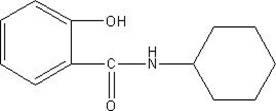

Image

Examples

Embodiment 1

[0039] For pipeline natural gas total pressure P=12MPa, P H2S =0.72MPa, P CO2 =0.93MPa, gas transmission capacity=300,000 cubic meters / day, condensate oil production=5.3t / day, water production=1.0t / day sour oil and gas field pipeline

[0040] Corrosion inhibitor formula:

[0041] Cyclohexamide Salicylate 20%

[0042] Pyridinium quaternary ammonium salt 10%

[0043] Sodium dodecylbenzenesulfonate 0.2%

[0044] Antioxidant BHT 0.2%

[0045] Descaler PAC 0.1%

[0046] Silicone oil defoamer 0.5%

[0047] Naphthenate 0.4%

[0048] Composite solvent 68.6%

[0049] Wherein the composite solvent is composed of the following components in mass percentage:

[0050] Ethanol 30%

[0051] Ethylene glycol 20%

[0052] water 50%

[0053] In accordance with the provisions of ASTM G170-06 "Standard Guide for Laboratory Evaluation and Verification of Corrosion Inhibitors in Oilfields and Refineries", the dynamic weight loss coupon test was carried out under simulated working conditi...

Embodiment 2

[0057] For pipeline natural gas total pressure P=14.5MPa, P H2S =0.55MPa, P CO2 =0.64MPa, gas transmission capacity=280,000 cubic meters / day, condensate oil production=0.3t / day, water production=2.1t / day sour oil and gas field pipeline

[0058] Corrosion inhibitor formula:

[0059] Cyclohexamide Salicylate 10%

[0060] Pyridinium quaternary ammonium salt 5%

[0061] Sodium dodecylbenzenesulfonate 0.1%

[0062] Antioxidant BHT 0.1%

[0063] Descaler PAC 0.2%

[0064] Silicone oil defoamer 0.3%

[0065] Naphthenate 0.3%

[0066] Composite solvent 84%

[0067] Wherein the composite solvent is composed of the following components in mass percentage:

[0068] Ethanol 50%

[0069] Ethylene glycol 30%

[0070] water 20%

[0071] In accordance with the provisions of ASTM G170-06 "Standard Guide for Laboratory Evaluation and Verification of Corrosion Inhibitors in Oilfields and Refineries", the dynamic weight loss coupon test was carried out under simulated working conditio...

Embodiment 3

[0075] It is used in sour oil and gas fields where the total pressure of pipeline natural gas is P=14.5MPa, PH2S=0.55MPa, PCO2=0.64MPa, gas transmission volume is 280,000 standard cubic meters per day, condensate oil production is 0.3t / day, and water production is 2.1t / day in the pipeline,

[0076] Corrosion inhibitor formula:

[0077] Cyclohexamide Salicylate 15%

[0078] Pyridinium quaternary ammonium salt 9%

[0079] Sodium dodecylbenzenesulfonate 0.1%

[0080] Antioxidant BHT 0.1%

[0081] Descaler PAC 0.1%

[0082] Silicone oil defoamer 0.3%

[0083] Naphthenate 0.4%

[0084] Composite solvent 75%

[0085] Wherein the composite solvent is composed of the following components in mass percentage:

[0086] Ethanol 40%

[0087] Ethylene glycol 20%

[0088] water 40%

[0089] In accordance with the provisions of ASTM G170-06 "Standard Guide for Laboratory Evaluation and Verification of Corrosion Inhibitors in Oilfields and Refineries", the dynamic weight loss coupon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com