Steel core wire free cutting line and manufacture method thereof

A steel wire core and cutting wire technology, which is applied in the manufacture of tools, stone processing equipment, cable/conductor manufacturing, etc., to achieve good wear resistance, improve cutting efficiency, and strong ability to carry sand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

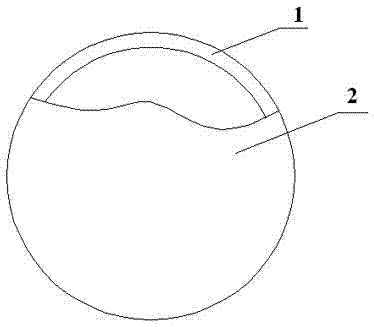

Image

Examples

Embodiment 1

[0022] A steel core wire free cutting wire, the preparation method of which is as follows: after coupling treatment of the surface-purified filler, mix it with a resin binder, then add a solvent and a curing agent, and mix evenly to obtain a slurry; then apply the slurry On the surface of the purified steel wire core wire, it is obtained after the diameter is limited and solidified, the details are as follows:

[0023] ①Steel wire purification treatment: A single stainless steel wire with a diameter of 0.1mm is degreased with 25wt% sodium hydroxide solution at 50~70°C. Sulfuric acid solution activated the surface for 5 minutes, washed with deionized water until neutral, and dried for later use.

[0024] ②Preparation of coating composite agent: The filler (the filler is composed of diamond micropowder, silicon carbide micropowder, aluminum oxide micropowder and copper powder) is treated with ultrasonic wave in acetone for 20 minutes (frequency 18 kHz) and then dried, followed b...

Embodiment 2

[0028] In this example, the difference from Example 1 is that the filler used is composed of diamond micropowder, copper powder, silicon carbide micropowder and aramid fiber chopped strands. The prepared slurry contains 2% diamond powder with a particle size of 0.5 microns, 8% silicon carbide powder with a diameter of 5 microns, 8% copper powder with a diameter of 2 microns and a volume content of 5% with a diameter of 5 microns. 1 mm aramid chopped strands.

[0029] The dicing wire produced had a diameter of 0.12 mm and a resin bond coating of about 10 microns.

Embodiment 3

[0031] In this embodiment, the difference from Embodiment 1 is that carbon steel wires are used instead of stainless steel wires.

[0032] The dicing wire produced had a diameter of 0.12 mm and a resin bond coating of about 10 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com