Benzimidazole ionic liquid aid used in rubber processing and preparation method thereof

A technology of benzimidazole and ionic liquid, applied in the field of rubber processing aids, can solve the problems of easy leaving mold scale and traces, uncommon release agent, mold corrosion, etc., and achieves low price, low production cost, and increased mechanical performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

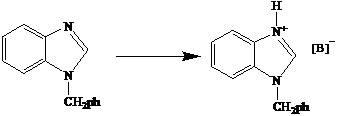

[0021] Preparation of 1-benzylbenzimidazolium bromide ionic liquid

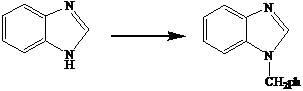

[0022] 1, the preparation of 1-benzylbenzimidazole

[0023] Add 2g benzimidazole, 20mL 40% NaOH and 0.2g (C 4 h 9 ) 4 NBr was heated to 55°C, and 2.4 mL of benzyl chloride was added under stirring. After reacting for 1 hour, a white solid precipitated out. The reaction mixture was poured into 50 mL of water and filtered. The filtered precipitate was dissolved in chloroform, washed 3 times with distilled water, and the organic phase was washed with anhydrous Na 2 SO 4 After drying, the solvent was evaporated under reduced pressure and recrystallized from benzene to obtain 1-benzylbenzimidazole.

[0024] 2. Preparation of 1-benzylbenzimidazolium bromate ionic liquid

[0025] Add 2.00 g of 1-benzylbenzimidazole and 30 mL of ethanol into the three-necked flask, and slowly add 2.00 mL of 6.93 mol / L HBr dropwise with stirring at room temperature. The reaction was stirred at room temperature for 2 hours. Et...

Embodiment 2

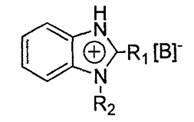

[0027] Preparation of 1-benzylbenzimidazole tetrafluoroborate ionic liquid

[0028] 1, the preparation of 1-benzylbenzimidazole

[0029] Add 2g benzimidazole, 30mL 40% NaOH aqueous solution and 0.3g (C 4 h 9 ) 4 NBr was heated to 55°C, and 3.5 mL of benzyl chloride was added under stirring. After 1.5 hours of reaction, a white solid precipitated. The reaction mixture was poured into 50 mL of water and filtered. The solid was dissolved in chloroform, washed three times with distilled water, and anhydrous Na 2 SO 4 dry. The solvent was distilled off under reduced pressure, and 1-benzylbenzimidazole was obtained by recrystallization from benzene.

[0030] 2. Preparation of 1-benzylbenzimidazole tetrafluoroborate ionic liquid

[0031] Weigh 2.45g of 1-benzylbenzimidazole, place it in a 100mL three-neck flask, add 30mL of acetone as a solvent, and stir at room temperature to completely dissolve the solid. Add 4mL 8mol / L HBF 4 aqueous solution, stirred at room temperature ...

Embodiment 3

[0033] Preparation of Ionic Liquid of 1-Benzylbenzimidazole Hexafluorophosphate

[0034] Weigh 2g of 1-benzylbenzimidazole obtained in Example 1, place it in a 250mL bottom flask, add 50ml of distilled water, then add 2mL of 10mol / L KPF 6 aqueous solution, stirred at room temperature for 1.5 hours, and evaporated the solvent under reduced pressure to obtain a crude product. The crude product was washed three times with ether, recrystallized from ethanol-ether (V / V, 1:1), and dried under vacuum at 70°C for 12 hours to obtain 1-benzylbenzimidazole hexafluorophosphate ionic liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com