Preparation method of stable-state chlorine dioxide solution of food additive

A technology for food additives and chlorine dioxide, applied in food preparation, chlorine oxide, food preservation, etc., can solve the problems of long process flow, uneconomical and difficult control, etc., achieve reasonable design of process flow, reduce bumping Spray and reduce the effect of methanol volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

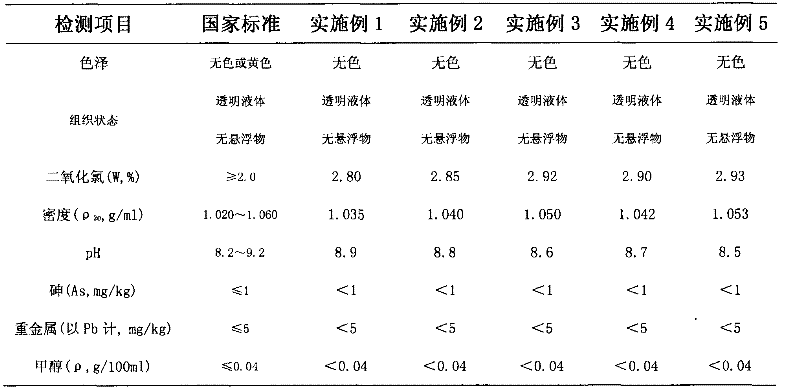

Examples

Embodiment 1

[0016] (1) 3.5kg of sodium chlorate aqueous solution of preparation mass concentration 30% is pumped into the reactor that establishs open pipe by water injection vacuum system, starts jacket heating device and is heated to 55 ℃;

[0017] (2) Dilute the concentrated sulfuric acid to a mass concentration of 60%. The obtained dilute sulfuric acid solution requires clear, transparent and free of suspended matter, and then mix it with methanol at a mass ratio of 1:0.05 to prepare 3.8kg of sulfuric acid methanol solution, which passes through the rotor from the high position tank The flow meter measures and controls the addition speed, and is continuously added to the reactor of step (1) for reaction;

[0018] (3) A water jet vacuum system is used to provide power, and the chlorine dioxide gas generated by the reaction in step (2) is cooled by a water cooler, and then enters the gas-liquid separator to separate the liquid foam and pickle for further purification;

[0019] (4) add w...

Embodiment 2

[0022] (1) Prepare 2.1kg of sodium chlorate aqueous solution with a mass concentration of 50%, add 0.1% sodium chloride (i.e. 2.1g) and mix evenly, and then pump it into the reaction kettle with open pipe through the water jet vacuum system, and enable jacket heating The device is heated to 50°C;

[0023] (2) Dilute the concentrated sulfuric acid to a mass concentration of 55%. The obtained dilute sulfuric acid solution requires clearness without suspended matter, and then mix it with methanol at a mass ratio of 1:0.08 to prepare 3.8kg of sulfuric acid methanol solution, which is passed through the rotor from the high position tank The flow meter measures and controls the addition speed, and is continuously added to the reactor of step (1) for reaction;

[0024] (3) A water jet vacuum system is used to provide power, and the chlorine dioxide gas generated by the reaction in step (2) is cooled by a water cooler, and then enters the gas-liquid separator to separate the liquid fo...

Embodiment 3

[0028] (1) 2.6kg of sodium chlorate aqueous solution of preparation mass concentration 40%, is pumped into the reactor that establishs open pipe by water injection vacuum system, enables jacket heating device to be heated to 60 ℃;

[0029] (2) Dilute the concentrated sulfuric acid to a mass concentration of 50%. The obtained dilute sulfuric acid solution requires clearness without suspended matter, and then mix it with methanol at a mass ratio of 1:0.10 to prepare 3.8kg of sulfuric acid methanol solution, which is passed through the rotor by the high position tank The flow meter measures and controls the addition speed, and is continuously added to the reactor of step (1) for reaction;

[0030] (3) A water jet vacuum system is used to provide power, and the chlorine dioxide gas generated by the reaction in step (2) is cooled by a water cooler, and then enters the gas-liquid separator to separate the liquid foam and pickle for further purification;

[0031] (4) add water to pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com