Preparation method of binary gradiently doped barium strontium titanate (BST) film

A gradient doping and binary doping technology, which is applied in the field of functional materials, can solve the problem that the comprehensive dielectric properties of BST films are difficult to improve, and achieve the effects of meeting the needs of microwave applications, small dielectric loss, and widening the Curie temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

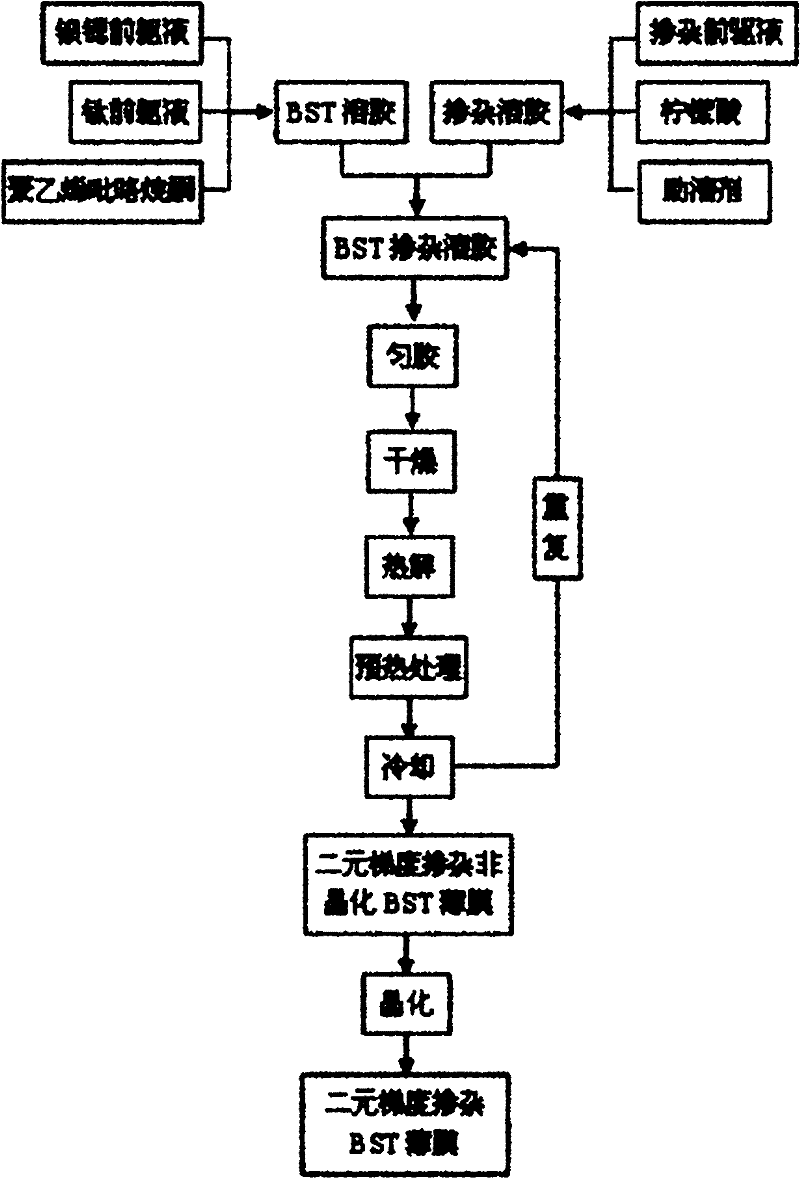

Method used

Image

Examples

Embodiment 1

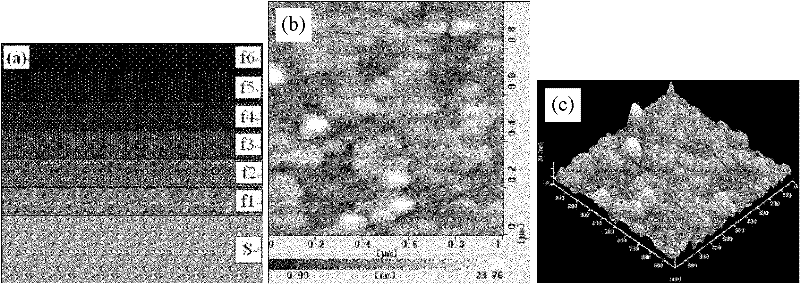

[0048] Embodiment 1: Gradient doping on yttrium and manganese (Ba 0.6 Sr 0.4 ) 0.8 TiO 3 Film preparation. Conditions: 6 layers, (Ba+Sr) / Ti=0.8, the doping concentration of the first film yttrium and manganese is 0.5% molar ratio, the doping concentration gradient is 0.1% molar ratio, the sixth layer film yttrium and manganese The doping concentration is 1% molar ratio. Its structural diagram is as figure 2 (a) shown.

[0049] Its preparation steps are as follows:

[0050] (1) Press (Ba 0.6 Sr 0.4 ) 0.8 TiO 3 The molar ratio of Ba, Sr, and Ti is 0.48:0.32:1 to prepare barium acetate, strontium acetate, and butyl titanate. Dissolve barium acetate and strontium acetate in hot glacial acetic acid to form a barium strontium precursor solution, and dissolve butyl titanate in Acetylacetone forms a titanium precursor solution; mix the two precursor solutions with 0.75% molar ratio of PVP to prepare a strontium barium titanate precursor solution, adjust the pH value to 3-4...

Embodiment 2

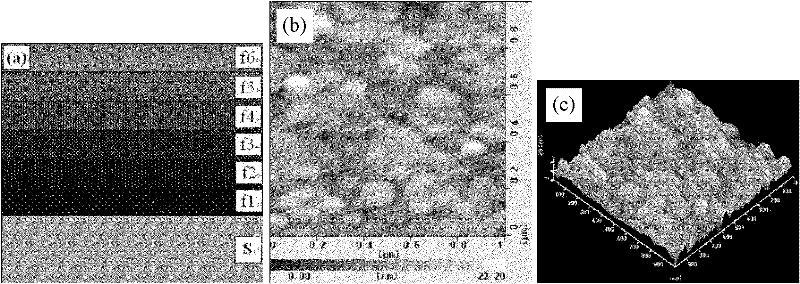

[0056] Embodiment 2: Gradient doping under yttrium and manganese (Ba 0.6 Sr 0.4 ) 0.8 TiO 3Film preparation. Conditions: 6 layers, (Ba+Sr) / Ti=0.8, the doping concentration of the first film yttrium and manganese is 1% molar ratio, the doping gradient is 0.1% molar ratio, the doping concentration of the sixth film yttrium and manganese The impurity concentration is 0.5% molar ratio. Its structural diagram is as image 3 (a) shown.

[0057] The preparation steps are as follows:

[0058] Steps (1)~(3) are identical with embodiment 1, just:

[0059] (4) Evenly drip BST sol with Mn and Y doping concentration of 1% molar ratio on the substrate, use CKF-411 type purification glue applicator to uniform glue at 3000~3500 rpm for 5~8 seconds, and then use Apply glue at 4500-5000 rpm for 25-30 seconds to form the first layer of wet film. The wet film is dried at 100-120°C for 5-10 minutes, pyrolyzed at 250-350°C for 10-15 minutes, preheated at 500-600°C for 10-15 minutes, and na...

Embodiment 3

[0062] Embodiment 3: Gradient doping on yttrium and manganese (Ba 0.6 Sr 0.4 ) 0.8 TiO 3 Film preparation. Conditions: 12 layers, (Ba+Sr) / Ti=0.8, the doping concentrations of Y and Mn in the first and second layers are both 0.5% molar ratio, and the doping concentrations in the third and fourth layers are both 0.6% Molar ratio, and so on, the doping gradient of two adjacent odd-numbered layers or even-numbered layers is 0.1% molar ratio, and the doping concentration of the eleventh and twelfth film is 1% molar ratio. Its structural diagram is as Figure 4 (a) shown.

[0063] The preparation steps are as follows:

[0064] Steps (1)~(3) are identical with embodiment 1, just:

[0065] (4) Evenly drip BST sol with Mn and Y doping concentration of 0.5% molar ratio on the substrate, use CKF-411 type purification glue applicator to uniform glue at 3000~3500 rpm for 5~8 seconds, and then use Apply glue at 4500-5000 rpm for 25-30 seconds to form the first layer of wet film. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com