Microbial flue gas desulfurizer

A desulfurizer and microorganism technology, applied in the field of microbial flue gas desulfurizer, can solve the problems of unsatisfactory, secondary pollution desulfurization rate, inability to implement industrialization promotion, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] 2. Preparation of desulfurizer

[0020] SO in existing pyrolusite 2 During the removal process, a high concentration of manganese ions (0.75% to 7.5%) will be produced. In order to enable the flora to perform its physiological functions normally in a high-concentration manganese ion environment, you can choose to adapt the flora to manganese ions. sexual domestication.

[0021] (1) The domesticated flora adapts to different concentrations of manganese ions:

[0022] Alicyclobacillus BM and acidophilic bacteria using reduced sulfur as an energy source were inoculated into Leatheren or 9K medium with a pH value of 4-5, respectively. Then culture at 30°C, 180rpm to OD 600 =0.5~0.6, then according to the ratio of Alicyclobacillus BM and acidophilic bacteria using reduced sulfur as the energy source, the ratio of 1:2 to 3 is mixed to make a mixed solution, and then the mixed solution is mixed with a ratio of 1:10 Add the ratio to the new Leatheren or 9K medium, and culti...

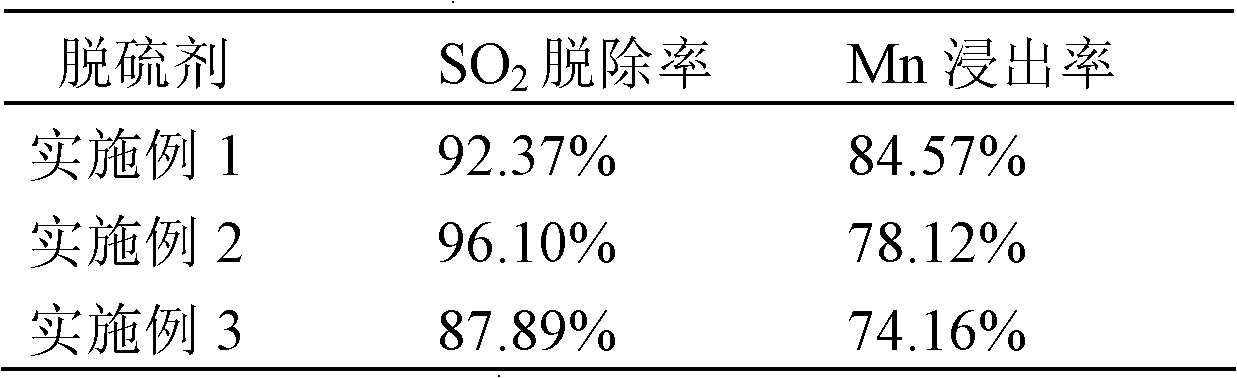

Embodiment 1

[0027] Alicyclobacillus BM and Thiobacillus thiooxidans were respectively cultured in leathern medium, and mixed according to the ratio of the number of bacteria to 1:3 to prepare 100L of desulfurizer, in which the concentration of viable bacteria was 1.5×10 9 CFU / ml. Add 10% pyrolusite powder in the desulfurizer, that is, 10 kg of pyrolusite powder (containing 15% manganese) is contained in 100L desulfurizer

Embodiment 2

[0029] After Alicyclobacillus BM, Thiobacillus thiooxidans and Thiobacillus ferrooxidans were cultured in 9K medium respectively, they were mixed according to the number of bacteria in a ratio of 1:2:2 to make a desulfurizer, and the concentration of viable bacteria was 2.9× 10 9 CFU / ml. Add 10 kg of pyrolusite (containing 15% manganese) into 100 L of desulfurizer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com