Method for preparing back incident silicon-based tellurium, cadmium and mercury focal plane anti-reflection film by femto-second laser

A femtosecond laser, mercury cadmium telluride technology, applied in the direction of final product manufacturing, sustainable manufacturing/processing, electrical components, etc., can solve the problems of poor reliability of anti-reflection coating, complicated operation process, etc., achieve small thermal effect, simplify preparation steps , the effect of low damage threshold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing, the specific embodiment of the present invention is described in further detail:

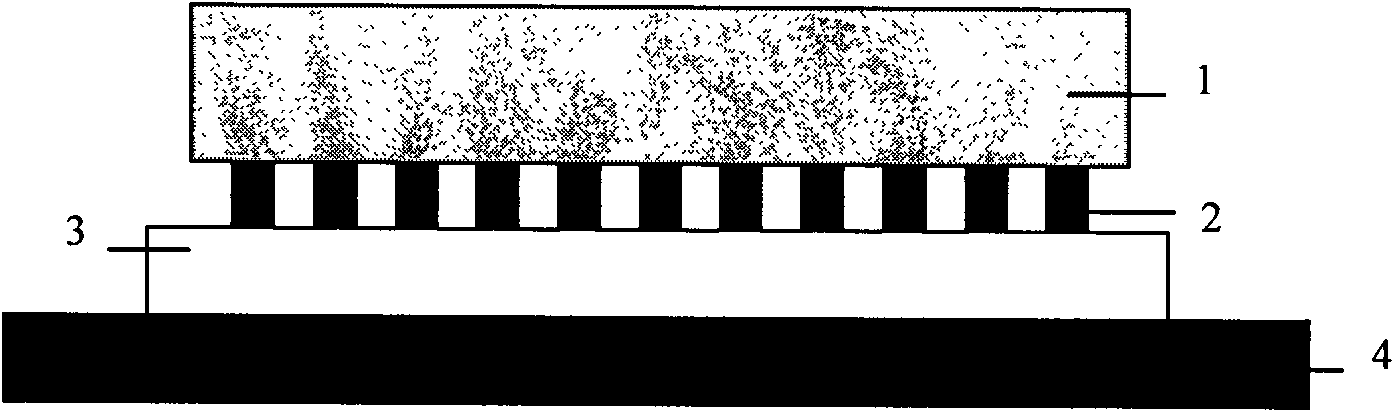

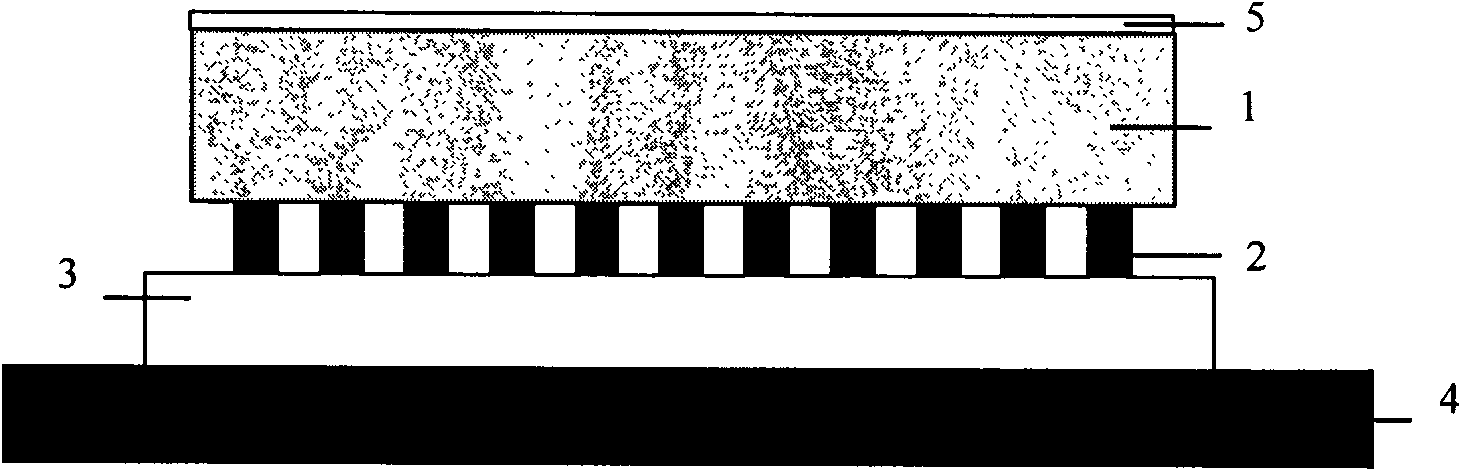

[0023] (1) The silicon-based mercury cadmium telluride infrared detector chip 1 is manufactured by using the conventional mercury cadmium telluride photovoltaic detector manufacturing process, and the chip and the silicon readout circuit 3 are interconnected by the indium column 2 through the cold pressure welding technology and pasted on the gemstone substrate 4 , and finally the prepared focal plane module ( figure 1 ) The chip substrate is placed on the three-dimensional mobile platform facing up.

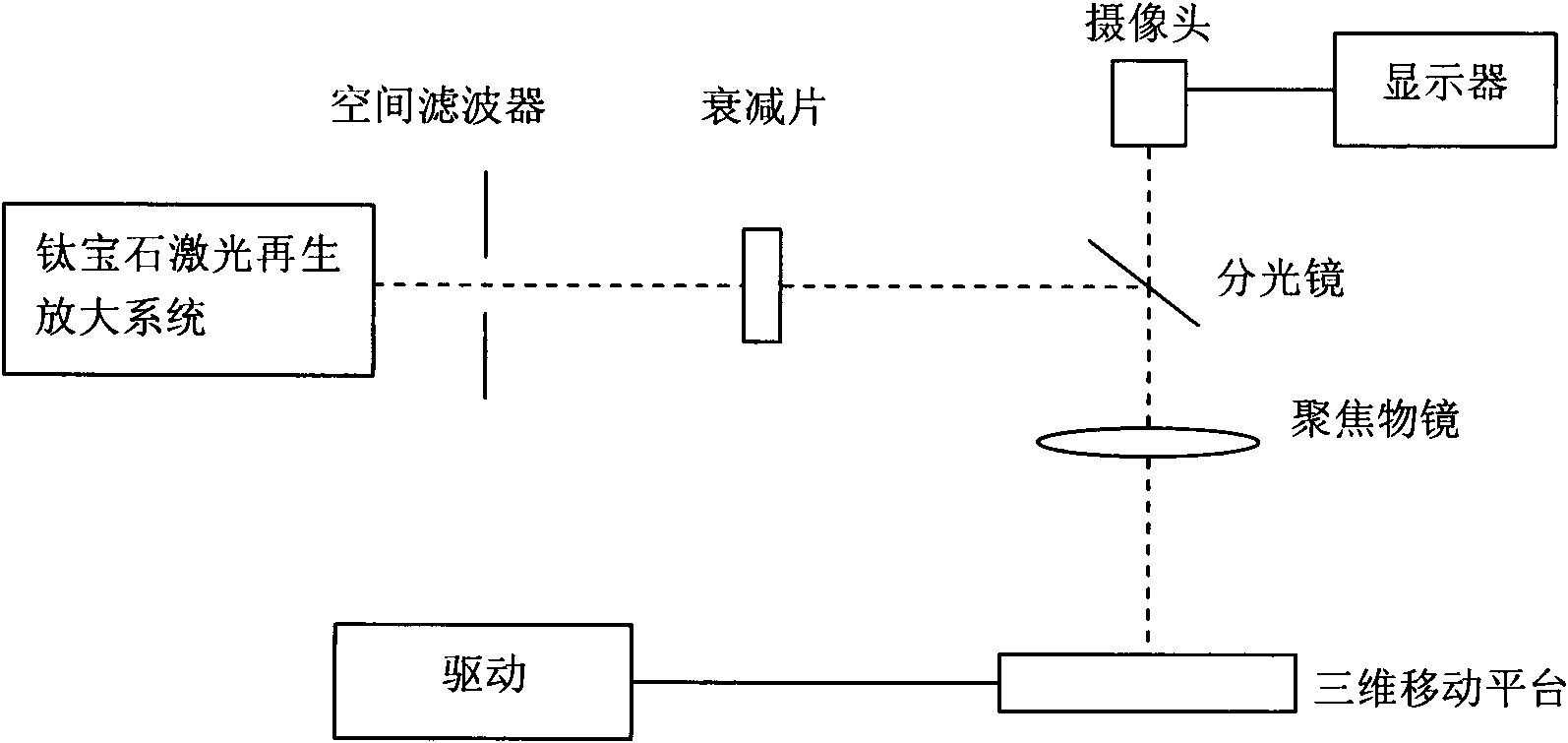

[0024] (2) Using a femtosecond laser to prepare an anti-reflection coating on the chip substrate at the focal plane of HgCdTe, the experimental device is as follows image 3 shown. The titanium sapphire laser regeneration amplification system is used as a light source, outputting laser pulses with a wavelength of 800nm, a pulse width of 60fs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com