Preparation method for graphene qxide

A graphene oxide and graphite oxide technology, which is applied to the preparation of graphene oxide with a thickness of a single atom or several atoms, and the field of graphene oxide preparation, which can solve the cumbersome method of graphene oxide and the inability to realize industrial production, etc. problem, to achieve the effect of good chemical activity, high yield and easy cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

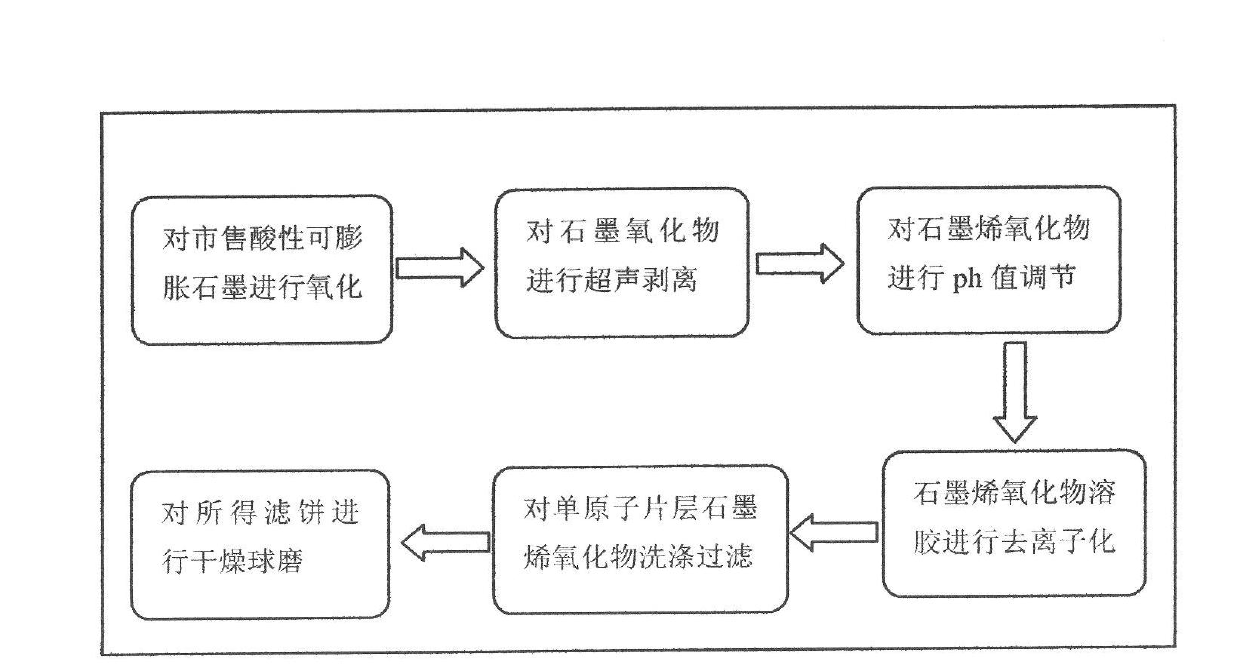

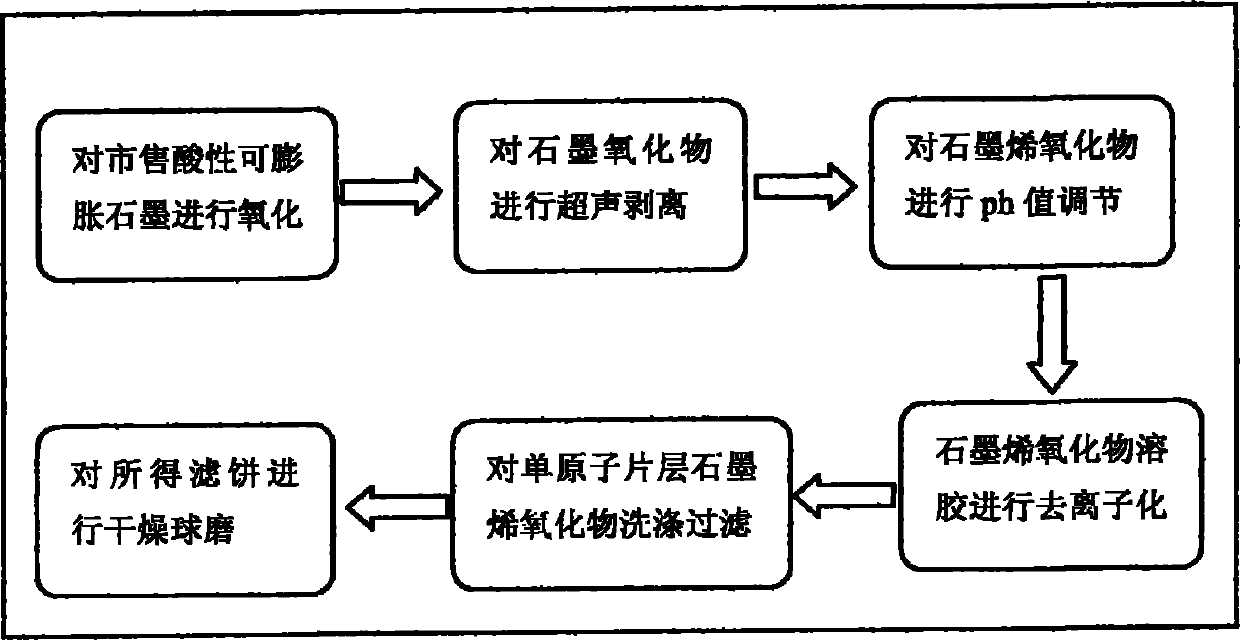

Method used

Image

Examples

Embodiment 1

[0036] Firstly, the commercially available acidic expandable graphite is oxidized by the following steps: 200ml of concentrated sulfuric acid and 2g of sodium nitrate are added to the flask with the magnetic rotor, and the flask is placed in an ice bath. The concentrated acid is stirred and then cooled in an ice bath for 15 minutes, and then 20 g of commercially available acidic expandable graphite is added to the concentrated acid and stirred evenly. Add 30g of potassium permanganate powder in 40min. The adding process needs to be slow. The adding speed should be controlled to avoid violent heating and keep the liquid temperature in the beaker not exceeding 5℃. After the potassium permanganate is added, the ice bath is removed. Slowly add 500ml of deionized water, and then heat the solution to raise the temperature of the solution to 100°C and keep it for 0.5-2h. The water bath was removed, the reaction was stirred, and the reaction was allowed to proceed at room temperature ...

Embodiment 2

[0043] Example 2 According to the method of Example 1, except that the strong acid is 180ml concentrated nitric acid, the same results as figure 2 As shown in the results, the yield can reach 179.5 %.

Embodiment 3

[0044] Example 3 According to the method of Example 1, except that the strong acid is 150ml perchloric acid, the same as figure 2 As shown in the results, the yield can reach 179.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com