Ferrocenecarboxylic acid modified unsaturated polyester resin and synthesis method thereof

A technology of ferrocenecarboxylic acid and polyester resin, which is applied in the field of ferrocenecarboxylic acid modified unsaturated polyester resin and its synthesis, to achieve the effects of easy curing and molding control, high thermal strength, good cohesiveness and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] (1) Add 130 parts by weight of ethylene glycol, 232 parts by weight of fumaric acid, and 1.5 parts by weight of monobutyltin oxide catalyst into the reactor, start stirring and heat up to make the material react at 200 ° C, Control the temperature of the fractionation column not to exceed 102°C;

[0018] (2) When the amount of water distilled from the reaction system is close to or reaches the theoretical water output, cool down to 160°C, add 46 parts by weight of ferrocenecarboxylic acid, feed inert gas, heat up to make the material react at a temperature of 200°C, and Control the temperature of the fractionation column not to exceed 102°C;

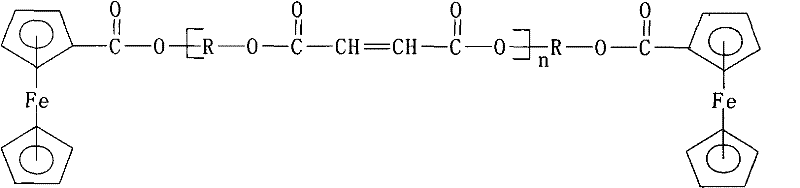

[0019] (3) After the acid value of the reaction material is less than 30mgKOH / g, close the inert gas valve, add 2 parts by weight of polymerization inhibitor hydroquinone, slowly open the vacuum system, and make the material continue to react under vacuum. When the acid value of the material is less than After 10mgKOH / g, the reac...

Embodiment 2

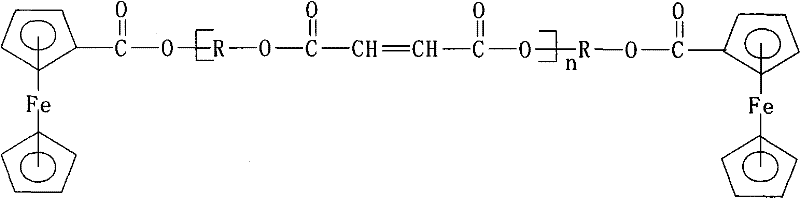

[0024] Embodiment 2: In Example 1, replace 130 parts by weight ethylene glycol with 160 parts by weight propylene glycol, the proportioning of all the other raw materials, the technology are unchanged, can obtain another kind of ferrocenecarboxylic acid modified unsaturated polysaccharide involved in the present invention. Ester resin, the structure is:

[0025]

[0026] Where: R=C 3 h 6 , n=20.

Embodiment 3

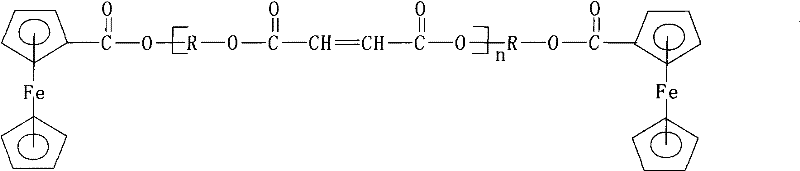

[0028] In Example 1, 130 parts by weight of ethylene glycol is replaced by 189 parts by weight of butanediol, and the proportioning and process of the remaining raw materials are unchanged, and another ferrocenecarboxylic acid modified unsaturated polyester resin related to the present invention can be obtained , with the structure:

[0029]

[0030] Where: R=C 4 h 8 , n=20.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Softening temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com