Silicon nanowire grating resonant enhanced photoelectric detector and manufacturing method thereof

A photodetector and silicon nanowire technology, applied in circuits, electrical components, semiconductor devices, etc., to achieve the effects of improving quantum efficiency, enhancing light field, and reducing source-drain bias voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

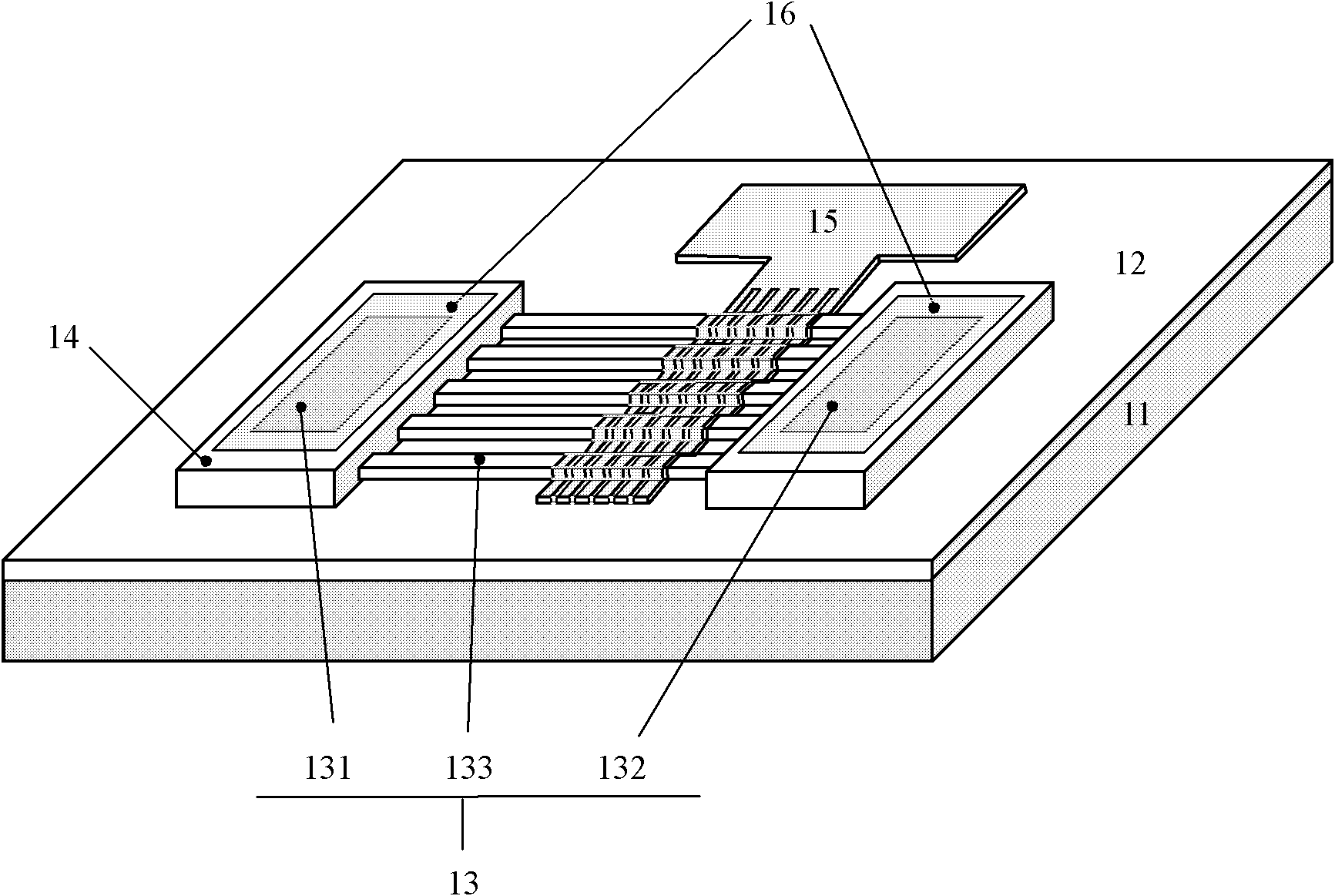

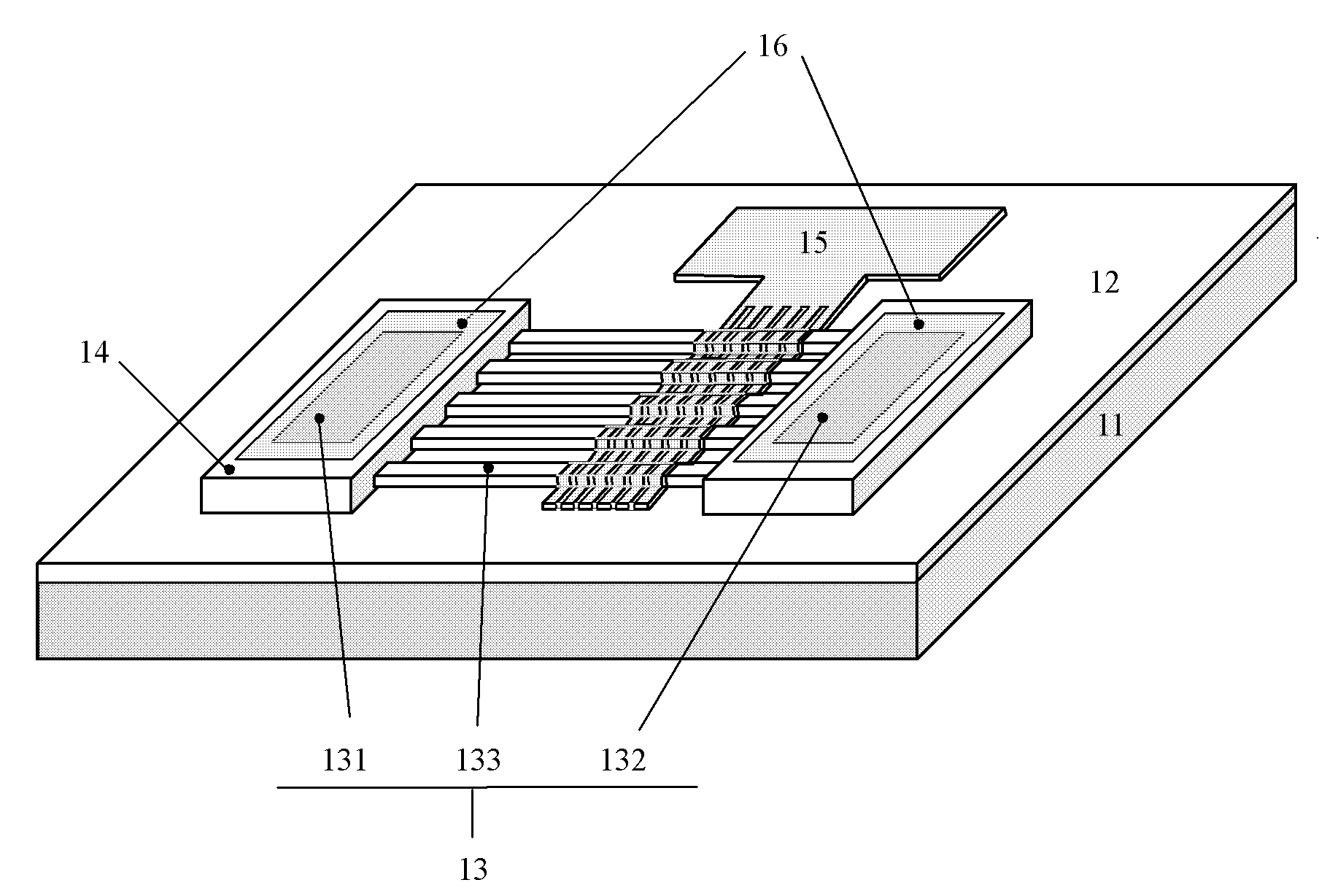

[0052] Please refer to figure 1 According to the invention, a silicon nanowire grating resonance enhanced photodetector can be fully compatible with CMOS technology, and is suitable for the application of optoelectronic hybrid integrated circuit (OEIC).

[0053] First, select a silicon substrate 11 (400 μm)-silicon oxide layer 12 (300nm)-an SOI (or SIMOX) sheet with a thin intrinsic top silicon layer (200nm) structure; thermally oxidize the 200nm-thick top-layer silicon at 900°C to obtain a 30nm-thick Thermal silicon oxide layer; cover the sample with 1 μm thick photoresist AZ6130, and then photo-etch the mask pattern of the I-shaped mesa 13 after pre-baking. After the silicon oxide is etched by ICP, the top silicon thin layer is etched by ICP. The silicon thin layer forms the I-shaped mesa 13 . Next, cover the sample with a 200nm thick photoresist PMMA950K, and dry it on a hot plate at 180°C for 90 seconds; use an electron beam exposure sleeve to carve out the mask layer of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com