Synthetic method of royaljelly acid

A synthesis method and a royal jelly acid technology, applied in the field of medicine, can solve the problems of poor selectivity, difficult product purification, increased side reactions, etc., and achieve the effects of high stereoselectivity, serious environmental pollution, and improved stereoselectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

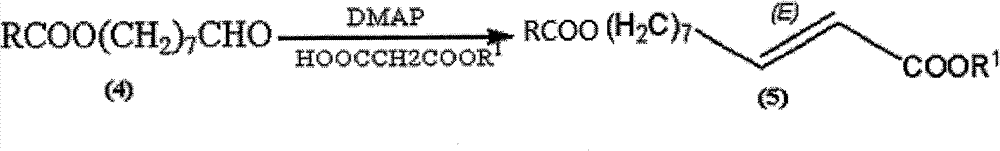

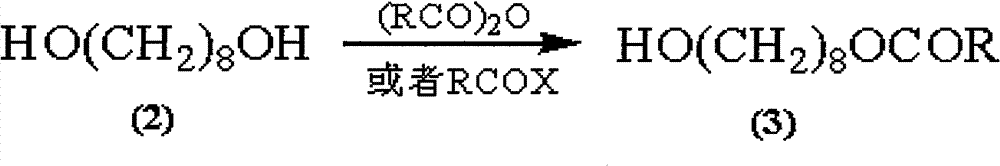

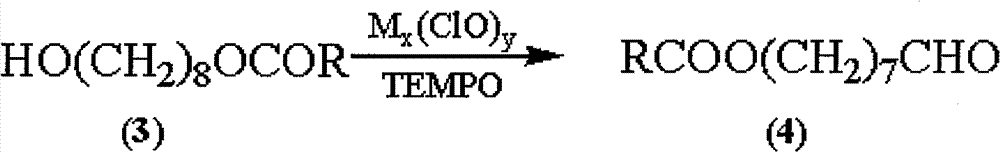

Method used

Image

Examples

Embodiment 1

[0043] Preparation of 8-acetoxy-1-octanol (3)

[0044] 1,8-octanediol (10.00 g, FW: 146.22; 68.40 mmol) was dissolved in 100 ml of ethyl acetate, then 100 g of silica (100 mesh) was added to the solution, stirred, and then the solvent was concentrated Removed to obtain 1,8-octanediol adsorbed on silica.

[0045] At the same time, in a 1000mL three-necked round-bottomed flask equipped with a mechanical stirrer, a thermometer, and a constant pressure dropping funnel, the above-mentioned adsorbate, 500ml of cyclohexane, and acetyl chloride (6.44g, FW: 78.50; 82.10mmol) were added to the system in sequence. middle. The reaction temperature was then raised to 60° C., at which stirring was continued for 2 hours. After the completion of the reaction, the temperature of the system was cooled to room temperature, and then the mixture was filtered, and the filter cake was fully washed with ethyl acetate until there was no product in the filter cake. A colorless filtrate was obtained,...

Embodiment 2

[0047] Preparation of 8-acetoxy-1-octanol (3)

[0048] 1,8-octanediol (10 g, FW: 146.22; 68.40 mmol) was dissolved in 100 ml of ether, then 50 g of silicon dioxide (100 mesh) was added to the solution, stirred, and then the solvent was concentrated and removed to obtain 1,8-octanediol is adsorbed on silica.

[0049] At the same time, in a 1000mL three-necked round-bottomed flask equipped with a mechanical stirrer, a thermometer, and a constant pressure dropping funnel, the above-mentioned adsorbate, 500ml of petroleum ether, and acetyl chloride (10.74g, FW: 78.50; 136.81mmol) were sequentially added to the system . The reaction was then stirred for 12 hours at 20°C. After the completion of the reaction, the temperature of the system was cooled to room temperature, and then the mixture was filtered, and the filter cake was fully washed with ethyl acetate until there was no product in the filter cake. A colorless filtrate was obtained, the organic phases were combined and the...

Embodiment 3

[0051] Preparation of 8-propionyloxy-1-octanol (3)

[0052] 1,8-octanediol (10g, FW: 146.22; 68.40mmol) was dissolved in 100 ml of ether, then 100 g of silicon dioxide (100 mesh) was added to the solution, stirred, and then the solvent was concentrated and removed to obtain 1 , 8-octanediol is adsorbed on silica.

[0053] At the same time, in a 1000mL three-neck round-bottomed flask equipped with mechanical stirring, a thermometer, and a constant pressure dropping funnel, the above-mentioned adsorbate, 500ml of petroleum ether, and propionyl chloride (12.66g, FW: 92.52; 136.81mmol) were added to the system in sequence. middle. The reaction was then stirred for 4 hours at 60°C. After the completion of the reaction, the temperature of the system was cooled to room temperature, and then the mixture was filtered, and the filter cake was fully washed with ethyl acetate until there was no product in the filter cake. A colorless filtrate was obtained, the organic phases were combi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com