Multi-channel active noise control system for power transformer

A control system and multi-channel technology, applied in the field of multi-channel active control systems, can solve the problems of large amount of calculation, limited installation space, and inability to increase the volume of equipment, etc., to achieve good channel expansion, good control effect, and favorable The effect of ventilation and heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] Embodiment: Measure the noise of the power transformer to be controlled. If the noise spectrum has obvious line spectrum components around 100Hz, 200Hz, and 300Hz, the present invention can be used.

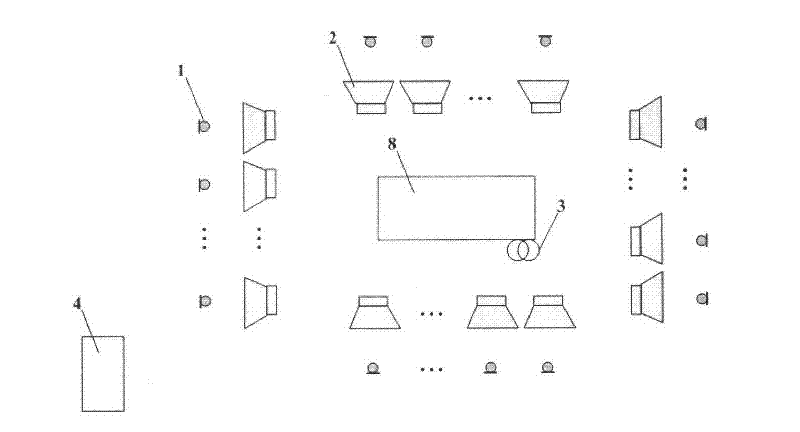

[0027] First, measure the sound field distribution of the power transformer noise line spectrum around 100Hz, 200Hz, and 300Hz and determine the amount of noise reduction that needs to be achieved. Then, according to the measured data and the number of control sources to be implemented, the position and number of the microphone and control sources are determined. Number is optimized. The optimization method used can be found in existing publications (translated by Yi Chuijie, Active Control of Noise and Vibration, Science Press, 2002; Chen Kean, Ma Yuanliang, Adaptive Active Noise Control-Principle, Algorithm and Implementation, published by Northwestern Polytechnical University Society, 1993).

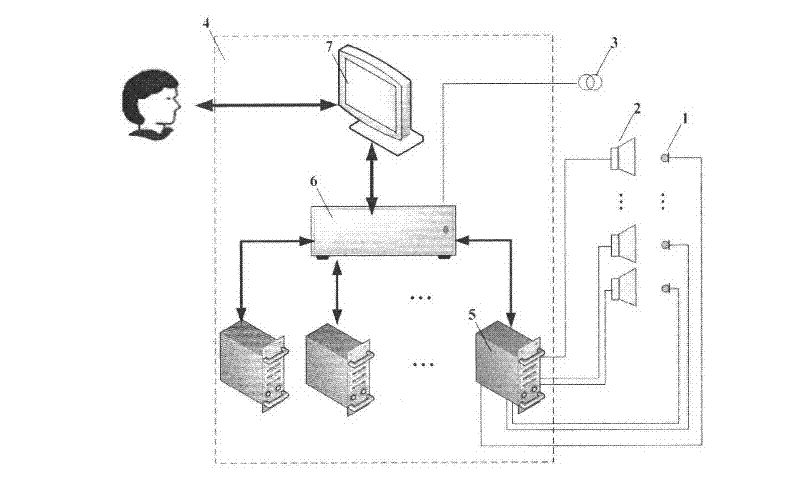

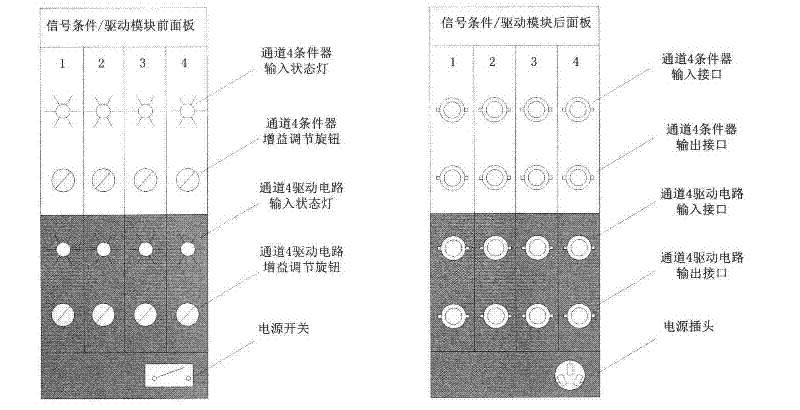

[0028] Such as Figure 5 As shown, the power transformer active noise contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com