Porous inorganic material with insecticidal and mothproof function and preparation method thereof

An inorganic material and pest control technology, applied in botany equipment and methods, biocide, biocide, etc., can solve the problems of high contact toxicity and complicated preparation process, and achieve the effect of low cost, mature process and increased adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

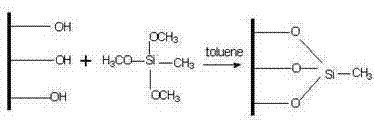

Method used

Image

Examples

Embodiment 1

[0029] Weigh 1g of montmorillonite into a 250ml three-necked flask, add 100ml of deionized water, adjust the pH to 4.0, and then add 0.1g of cationization reagent glycidyltrimethylammonium chloride to the montmorillonite suspension solution, the reaction was stirred at 20°C for 1 h, and then the filtered product was vacuum-dried at 50°C to constant weight. The vacuum-dried product was added to an organic solvent of a silane coupling agent, the silane coupling agent being 0.1 g of 3-aminopropyltrihexyloxysilane, and the organic solvent being 50 ml of methanol. React at a temperature of 80°C for 12 hours, filter the product and wash three times with methanol and acetone, and dry the washed product in vacuum at 50°C for 10 hours to obtain glycidyltrimethylammonium chloride cationized and Silane coupling agent alkylated montmorillonite.

[0030] Add 0.01g of the above product to 10ml of bifenthrin methanol solution with a concentration of 1g / l, shake and adsorb in a constant temp...

Embodiment 2

[0032] Weigh 5g of SBA-15 into a 250ml three-necked flask, add 100ml of deionized water, adjust the pH to 7.0, and then add 1g of cationization reagent glycidyltrimethylammonium chloride to the SBA-15 suspension , the reaction was stirred at 40°C for 2h, and then the filtered product was vacuum-dried at 50°C to constant weight. The vacuum-dried product was added to an organic solvent of a silane coupling agent, the silane coupling agent being 0.5 g of 3-chloropropyltrimethoxysilane, and the organic solvent being 100 ml of methanol. React at a temperature of 80°C for 14 hours. After the product is filtered, the filter cake is washed three times with methanol and acetone. The washed product is vacuum-dried at 50°C for 10 hours to obtain the glycidyltrimethylammonium chloride cation Alkylation and silane coupling agent SBA-15.

[0033] Add 0.5g of the above product to 10ml of fipronil methanol solution with a concentration of 10g / l, shake and adsorb in a constant temperature sha...

Embodiment 3

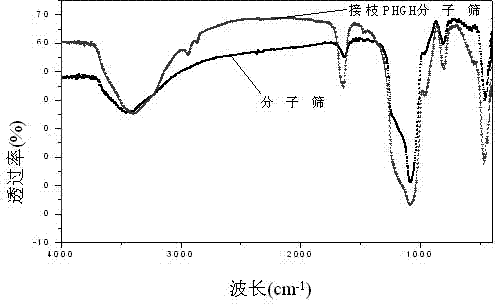

[0035] Weigh 1g of MCM-41 and add it to a 250ml three-necked flask, add 100ml deionized water, adjust the pH value to 9.0, then add 0.5g epichlorohydrin and 0.5g polyhexamethylene guanidine hydrochloride (PHGH) to In the MCM-41 suspension, the reaction was stirred at 70° C. for 2 h, and then the filtered product was vacuum-dried at 70° C. to constant weight. The vacuum-dried product was added into an organic solvent of a silane coupling agent, the silane coupling agent being 1 g of methyltrimethoxysilane, and the organic solvent being 50 ml of acetone. React at a temperature of 80°C for 24 hours, filter the product and wash it three times with acetone and absolute ethanol, and dry the washed product in a vacuum at 80°C for 10 hours to obtain a cationized and silane coupling agent-alkylated product. MCM-41.

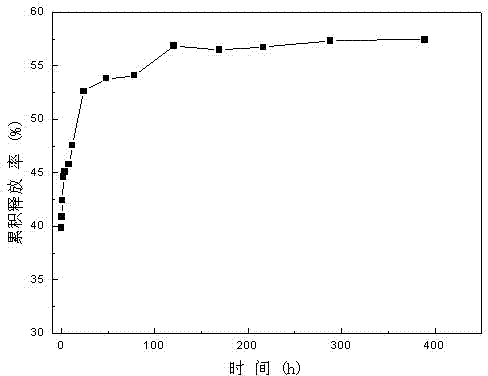

[0036] Add 0.1 g of the above product to 10 ml of imidacloprid acetone solution with a concentration of 8 g / l, shake and adsorb in a constant temperature shaker at 200 rp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com