Preparation method of antibacterial dressing for promoting wound healing

A wound dressing, bacterial cellulose technology, applied in the fields of medical science, absorbent pads, bandages, etc., can solve the problems of easy degradation, unable to control drug release, etc., and achieve the effect of strong antibacterial ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

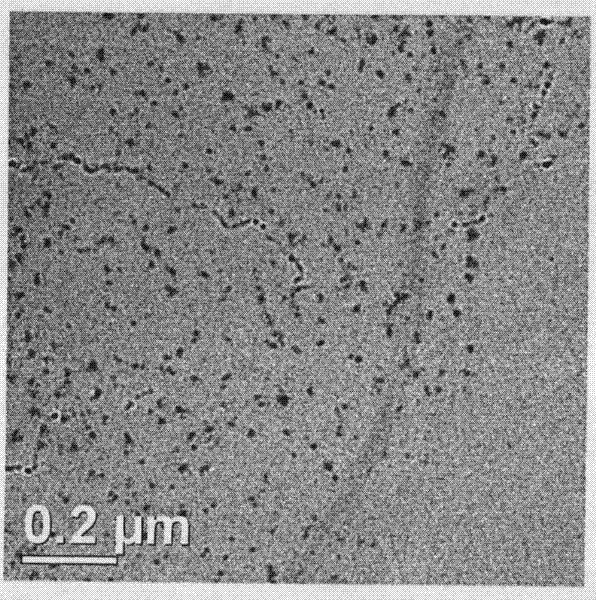

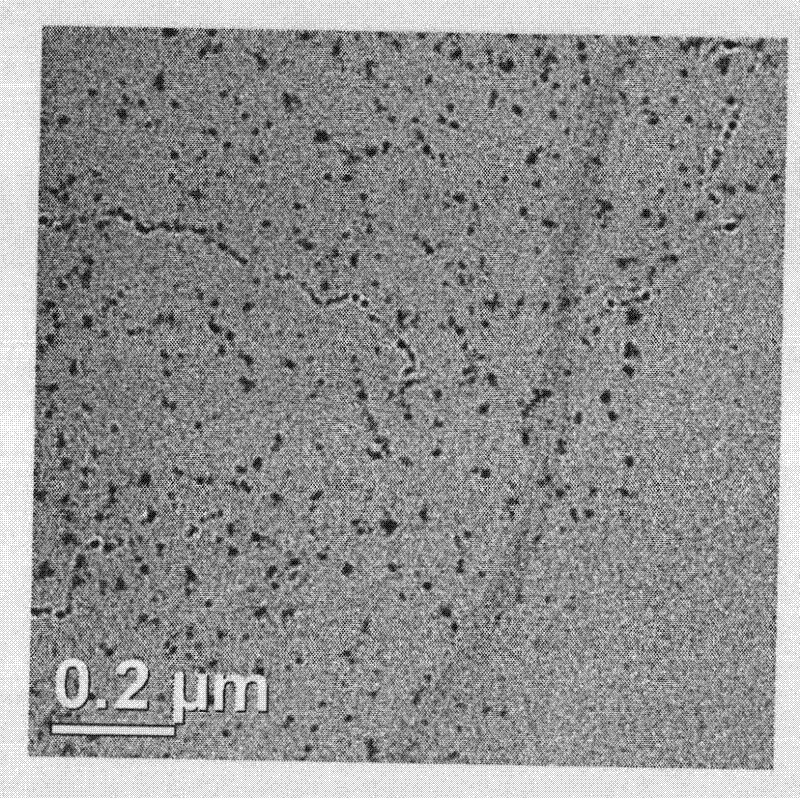

Image

Examples

preparation example Construction

[0015] The preparation method of the antibacterial and healing-promoting wound dressing of the present invention comprises the following steps:

[0016] In the first step, the wet flocculent bacterial cellulose is rinsed and then added to an alkali solution for heat treatment, then neutralized with an acid solution, and then washed with deionized water until neutral; the bacterial cellulose is prepared by a dynamic fermentation method, and the alkali The solution is a mixture of one or more of sodium hydroxide, potassium hydroxide and sodium carbonate, and the concentration of the alkali solution is 1%-4%.

[0017] In the second step, the product obtained in the first step is immersed in a silver salt solution, and then the solid is separated by filtration, and after washing with deionized water, a reducing agent is added and reacted under stirring conditions, and then the obtained product is rinsed and removed. Moisture removal; the silver salt is silver nitrate or silver 2-e...

Embodiment 1

[0024] The first step is to pretreat the wet flocculent bacterial cellulose, that is, add 1% sodium hydroxide alkali solution after rinsing and keep warm at 90°C for 3 hours, then neutralize with acetic acid solution, and then wash with deionized water until neutral;

[0025] In the second step, the product obtained in the first step is placed in 0.005mol / L AgNO3 silver salt solution and immersed, then filtered and separated to obtain a solid, then washed with deionized water, and then added ascorbic acid to reduce silver ions under mechanical stirring conditions, React at room temperature for 3 hours, rinse the product and remove 80% of the water in the system;

[0026] In the third step, soak the product obtained in the second step with 3% hyaluronic acid, remove 80% of the water in the system, add 2% carbodiimide cross-linking agent, and react at 30°C for 24 hours.

[0027] In the fourth step, the product of the third step is separated by filtration, washed three times with...

Embodiment 2

[0031] The first step is to pretreat the wet flocculent bacterial cellulose, that is, add 1% potassium hydroxide alkali solution at 90°C for 3 hours after rinsing, then neutralize with acetic acid solution, and then wash with deionized water until neutral;

[0032] In the second step, the product obtained in the first step is immersed in 0.008mol / L AgNO3 silver salt solution, then filtered to separate the solid, and after washing with deionized water, potassium borocyanide is added under mechanical stirring to reduce Silver ions, react at room temperature for 6 hours, rinse the product and remove 70% of the water in the system;

[0033] In the third step, after soaking the product obtained in the second step with 2.5% hyaluronic acid, remove 70% of the water in the system, and add 2% 1-(3-dimethylaminopropyl)-3-ethyl Based on carbodiimide crosslinking agent, react at 30°C for 24h.

[0034] In the fourth step, the product of the third step is separated by filtration, washed th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com