Method for preparing ZnIn2S4 visible-light activated photocatalyst at low temperature

A znin2s4, visible light technology, applied in chemical instruments and methods, physical/chemical process catalysts, general water supply conservation, etc., can solve the problems of high carcinogenicity, etc., and achieve the effect of easy implementation, simple equipment and process, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

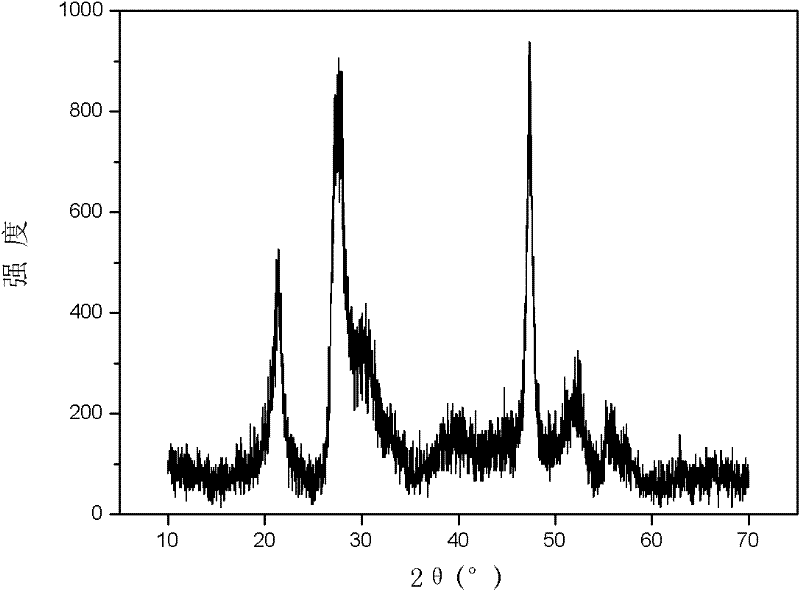

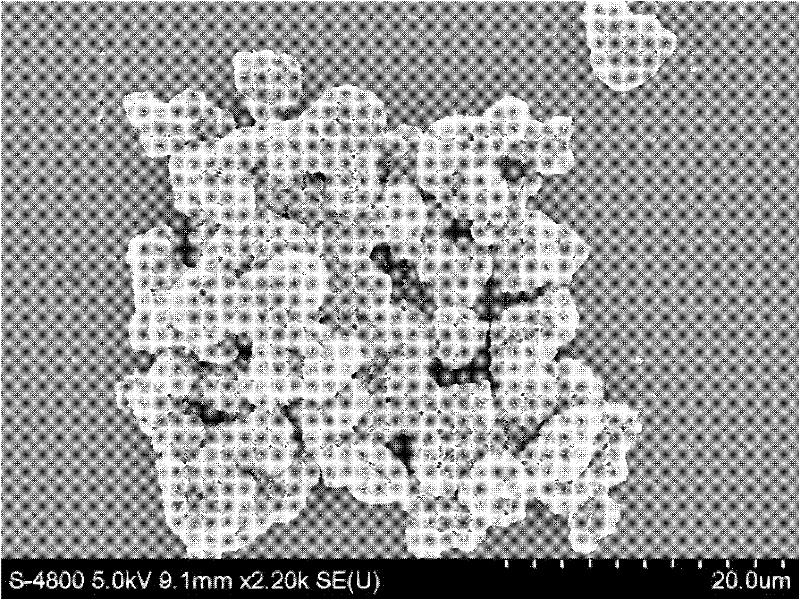

[0025] Accurately weigh 0.25mmol Zn(NO 3 ) 2 ·6H 2 O, 0.5mmol In(NO 3 ) 3 ·4.5H 2 Put O and 1.5mmol of thioacetamide into a 50mL PTFE liner, use a pipette to accurately pipette 15mL of deionized water as a solvent, and magnetically stir for 40 minutes to obtain a colorless and clear solution. Seal the stainless steel reactor. React at 70°C for 16h. After cooling, it was washed three times with absolute ethanol and deionized water, and dried overnight at room temperature to obtain a yellow powder. The yellow powder was X-ray powder diffraction (attached figure 1 )Identified as hexagonal ZnIn 2 S 4 , And there are no impurities in the product. The morphology was characterized by scanning electron microscopy (attached figure 2 ) Is a microsphere or irregular shape, with a particle size of 20um-100um.

[0026] Accurately pipette 250mL methyl orange dye wastewater into a glass reactor with a volume of 250mL. Add 0.1g ZnIn 2 S 4 For particle powder, the reaction system is placed in...

Embodiment 2

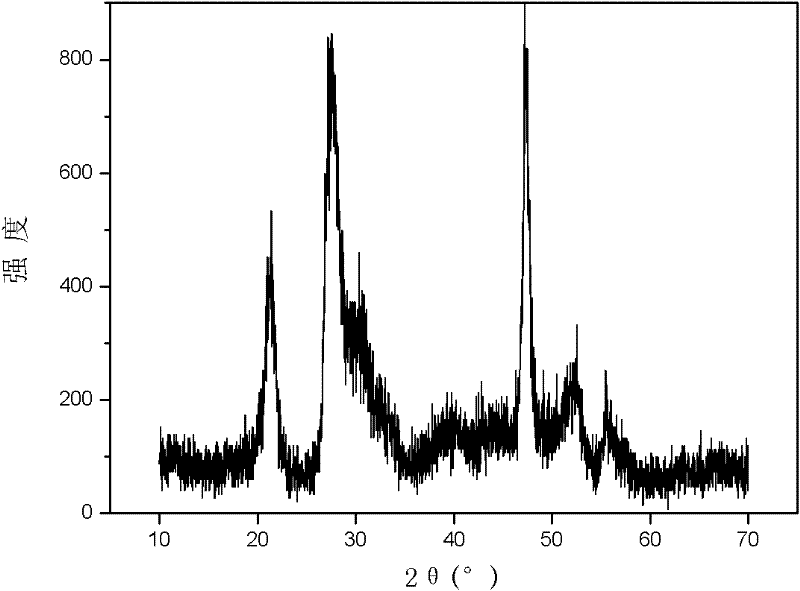

[0028] Repeat Example 1, with other conditions unchanged, and change the reaction time to 8h. The resulting product was X-ray powder diffraction (attached image 3 )Identified as hexagonal ZnIn 2 S 4 . The reaction results of the degradation of methyl orange wastewater were: after 1h of light, the degradation rate of methyl orange was 43.1%; after 2h of light, the degradation rate was 79.8%; after 2.5h of light, the degradation rate was 93.5%; after 3h of light, it was completely degraded.

Embodiment 3

[0030] Repeat Example 1, with other conditions unchanged, and change the reaction temperature to 55°C. The resulting product was X-ray powder diffraction (attached Figure 4 )Identified as hexagonal ZnIn 2 S 4 , Morphology by scanning electron microscope (attached Figure 5 ) Is characterized by microspheres or irregularities. The reaction results of the degradation of methyl orange wastewater were: after 0.5h of light, the degradation rate of methyl orange was 51.3%; after 1h of light, the degradation rate was 83.5%; after 1.5h of light, it was completely degraded.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com