Method for high-efficiency floatation and separation of molybdenum and nickel and recovery of molybdenum and nickel from high carbon nickel-molybdenum ore to obtain molybdenum concentrate and nickel-molybdenum bulk concentrate

A high-carbon molybdenum-nickel ore and mixed concentrate technology, applied in flotation, solid separation, etc., can solve the problems of no comprehensive recovery of metals, low recovery rate of nickel and molybdenum, and high production costs, so as to improve smelting recovery rate and product quality. Quality, reduce metallurgical cost, reduce the effect of production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

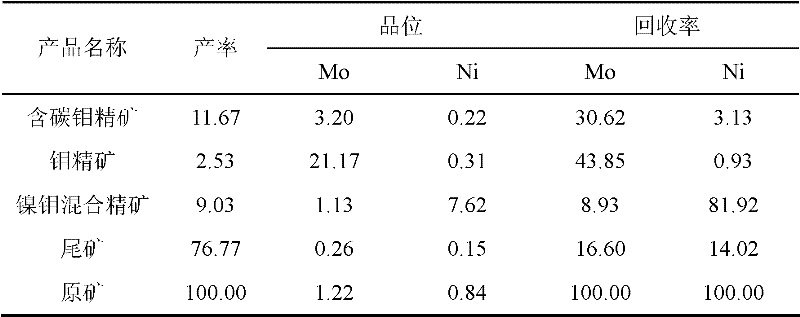

[0018] Example 1: A method for efficiently flotation-separating molybdenum-nickel from high-carbon molybdenum-nickel ore to recover molybdenum-nickel to obtain molybdenum concentrate and nickel-molybdenum mixed concentrate. The raw ore contains 1.22% molybdenum, 0.84% nickel, and a carbon content of up to 18%. Around, the oxidation rate of nickel and molybdenum is greater than 30%; the molybdenum part is adsorbed on the carbon particles in the form of ions, and mainly occurs in the carbonaceous shale on the broken zone between the rock layers, and part of the molybdenum exists in the colloidal pyrite and inside various nodules; nickel minerals mainly exist in the form of disulfide nickel ore, arsenite, pyrite nickel ore, goethite and nickel huabi alum, and some nickel and colloid pyrite are closely symbiotic .

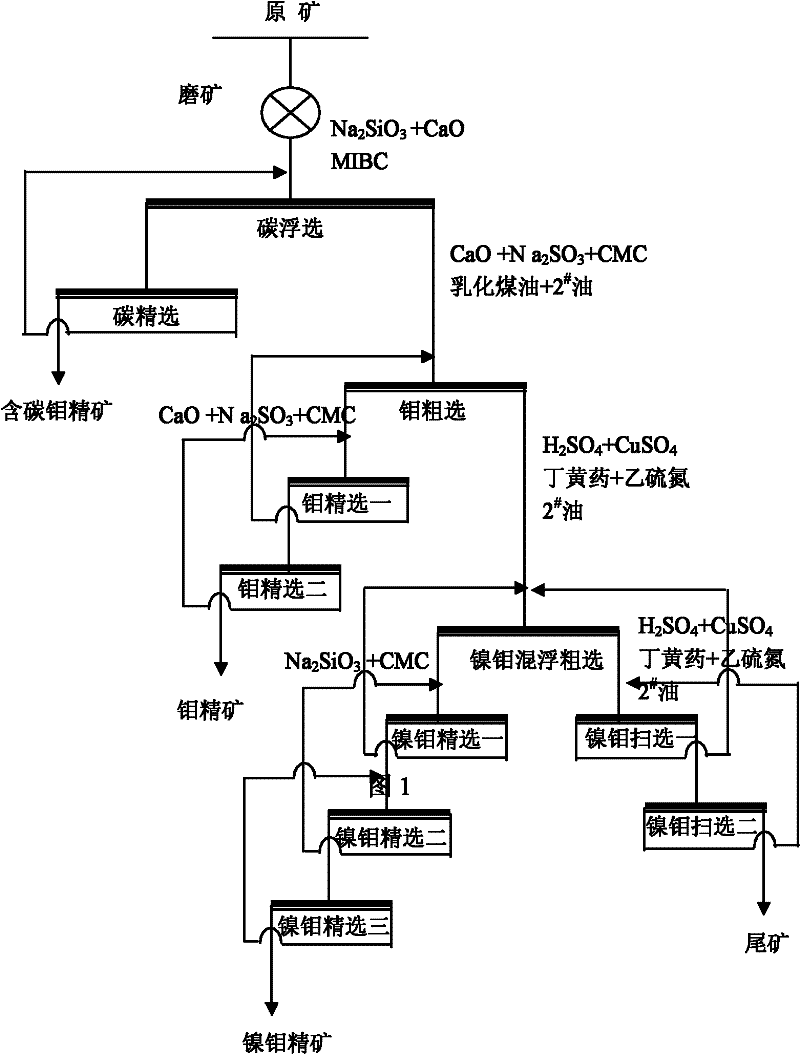

[0019] The process consists of raw ore selection, ore grinding, flotation decarburization, nickel-molybdenum separation flotation, and nickel-molybdenum mixed flotat...

Embodiment 2

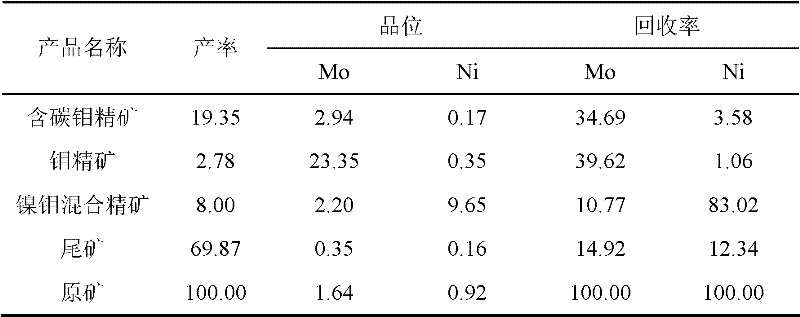

[0025] Example 2: A method for efficiently flotation-separating molybdenum-nickel from high-carbon molybdenum-nickel ore to recover molybdenum-nickel to obtain molybdenum concentrate and nickel-molybdenum mixed concentrate. The raw ore contains 1.64% molybdenum, 0.92% nickel, and a carbon content of up to 23%. about.

[0026] The process consists of raw ore selection, ore grinding, flotation decarburization, nickel-molybdenum separation flotation, and nickel-molybdenum mixed flotation; the raw ore is ground by a ball mill, and the grinding fineness is 75%-200 mesh. High-carbon molybdenum-nickel ore contains high carbon content, and it is decarburized by flotation. Add 65g / ton of water glass and 680g / ton of lime as dispersant and pH adjuster in flotation decarbonization operation, 40g / ton of MIBC as foaming agent and collector, after stirring, enter the flotation machine for decarburization carbon flotation. The decarbonization operation obtains flotation carbon-containing mo...

Embodiment 3

[0031] Embodiment 3: The high-carbon molybdenum-nickel ore high-efficiency flotation separation of molybdenum and nickel reclaims molybdenum and nickel to obtain molybdenum concentrate and nickel-molybdenum mixed concentrate. The method includes the following steps:

[0032] (1) After the raw ore is ground, the fineness of the mineral material is such that the mineral material with a particle size of less than 0.074mm accounts for 68%-73% of the total grinding material, and then flotation is carried out; the flotation is first carried out by decarbonization flotation beneficiation operation to obtain carbon-containing molybdenum concentrate and decarbonized tailings;

[0033] (2) The obtained decarburized tailings are subjected to preferential flotation of molybdenum to obtain molybdenum roughing concentrate and molybdenum roughing tailings; the molybdenum roughing concentrate is then subjected to two beneficiation operations to obtain the final molybdenum concentrate product; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com