Titanium dioxide polyaniline composite nanometer tube array and preparation method thereof

A nanotube array, titanium dioxide technology, applied in nanostructure manufacturing, nanotechnology, nanotechnology and other directions, can solve the problems of unique properties of unfavorable composite materials, limited application fields, weak force and other problems, and achieves simple and easy follow-up operations. , Improve the electron conductivity, the effect of uniform diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The concrete steps of preparation are:

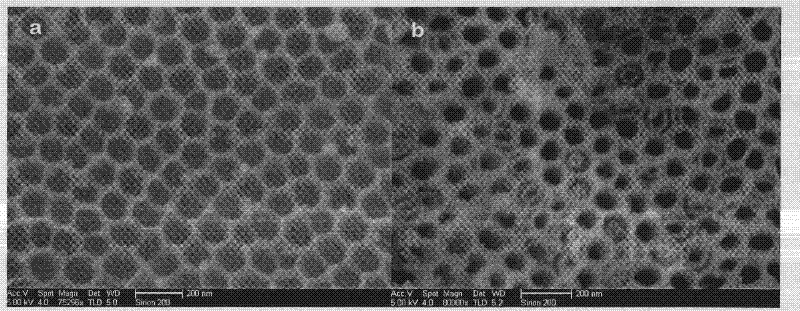

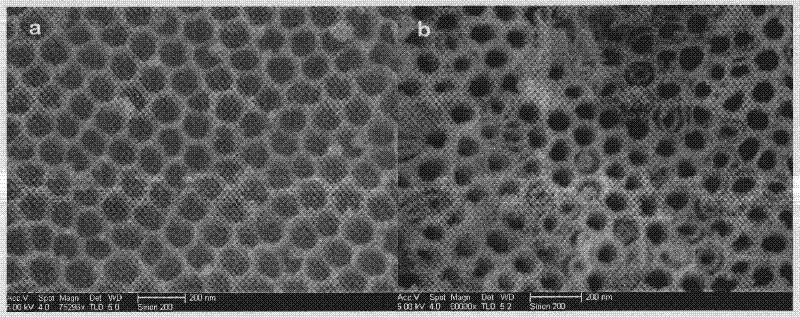

[0023] Step 1, first put the metal titanium sheet as the anode and the graphite sheet as the cathode in the electrolyte, and anodize at a DC voltage of 50V for 2.5 hours; wherein, the purity of the metal titanium sheet is 99.9%, and the electrolyte is composed of 0.2wt% It is formed by mixing ammonium fluoride, 1.6wt% of water and the balance of ethylene glycol. Then place it in deionized water or distilled water and ultrasonically clean it for 3 minutes and then dry it. Next, the anodized side is subjected to anodic oxidation for the second time under the same process conditions for 2.5 hours, and then it is washed and dried; wherein, the washing and drying process is performed after cleaning with ethanol. Drying at 50°C yields approximately figure 1 a TiO2 nanotube array with an inner diameter of 90 nm and a tube length of 30 μm shown in a.

[0024] In step 2, the titanium dioxide nanotube array is first heat-treated in wate...

Embodiment 2

[0027] The concrete steps of preparation are:

[0028] Step 1, first put the metal titanium sheet as the anode and the graphite sheet as the cathode in the electrolyte, and anodize at a DC voltage of 55V for 2.3 hours; wherein, the purity of the metal titanium sheet is 99.99%, and the electrolyte is composed of 0.25wt% It is formed by mixing ammonium fluoride, 1.7wt% water and the balance being ethylene glycol. Then place it in deionized water or distilled water and ultrasonically clean it for 3.5 minutes and then dry it. Then, the anodized side is first anodized for the second time under the same process conditions for 2.3 hours, and then it is washed and dried; wherein, the washing and drying process is cleaned with ethanol Drying at 50°C yields approximately figure 1 a TiO2 nanotube array with an inner diameter of 95 nm and a tube length of 25 μm.

[0029] Step 2, heat-treating the titanium dioxide nanotube array in water vapor at a temperature of 103°C for 28 minutes, a...

Embodiment 3

[0032] The concrete steps of preparation are:

[0033] Step 1, first put the metal titanium sheet as the anode and the graphite sheet as the cathode in the electrolyte, and anodize it at a DC voltage of 60V for 2 hours; wherein, the purity of the metal titanium sheet is 99.9%, and the electrolyte is composed of 0.3wt% fluorine It is formed by mixing ammonium chloride, 1.8wt% water and the balance being ethylene glycol. Then place it in deionized water or distilled water and ultrasonically clean it for 4 minutes and then dry it. Then, the anodized side was first anodized for the second time under the same process conditions for 2 hours, and then it was washed and dried; wherein, the washing and drying were cleaned with ethanol at 50 and dried at ℃ to obtain figure 1 a TiO2 nanotube array with an inner diameter of 100 nm and a tube length of 20 μm shown in a.

[0034] In step 2, the titanium dioxide nanotube array is first heat-treated in water vapor at a temperature of 105°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Tube chief | aaaaa | aaaaa |

| Tube wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com