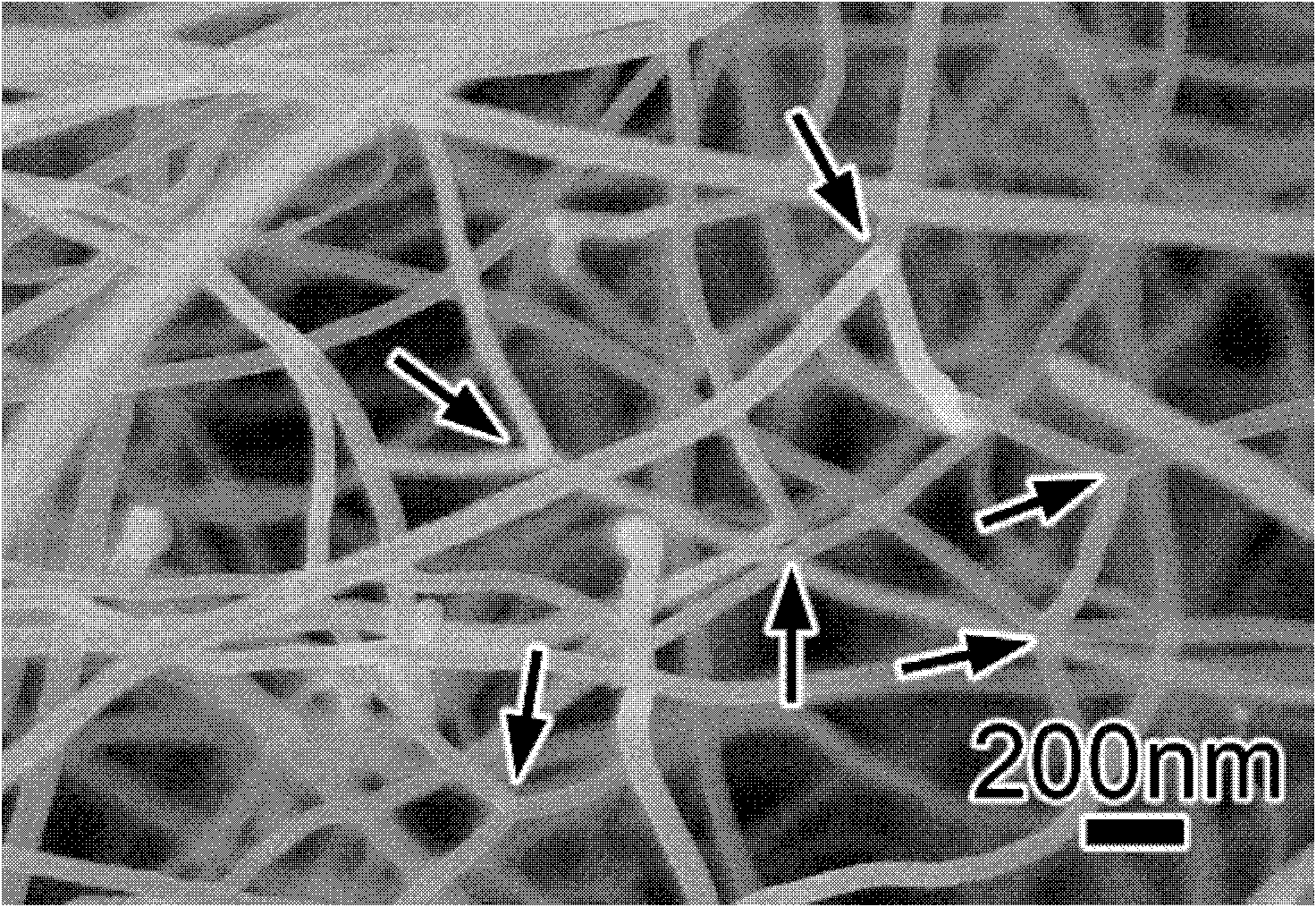

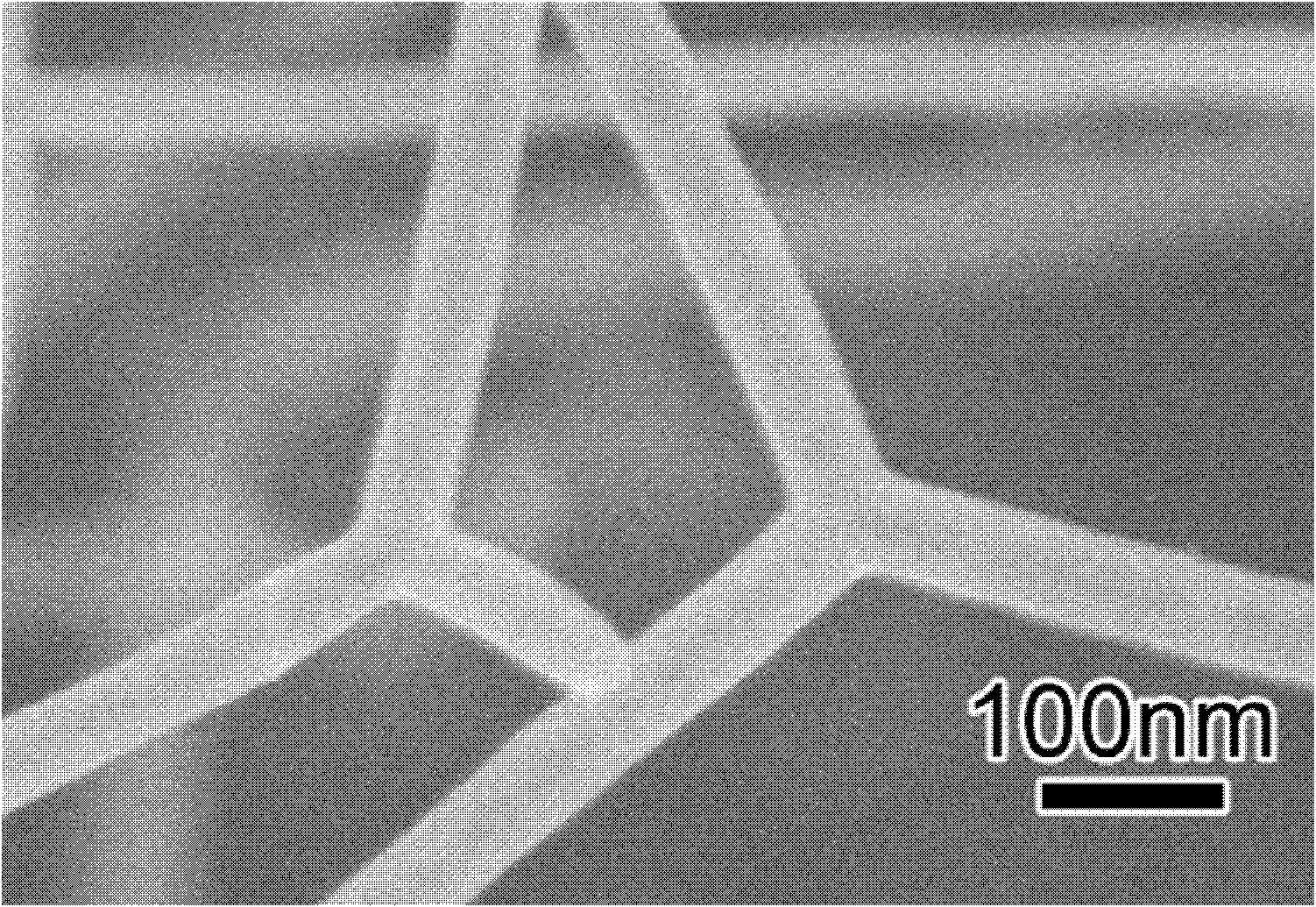

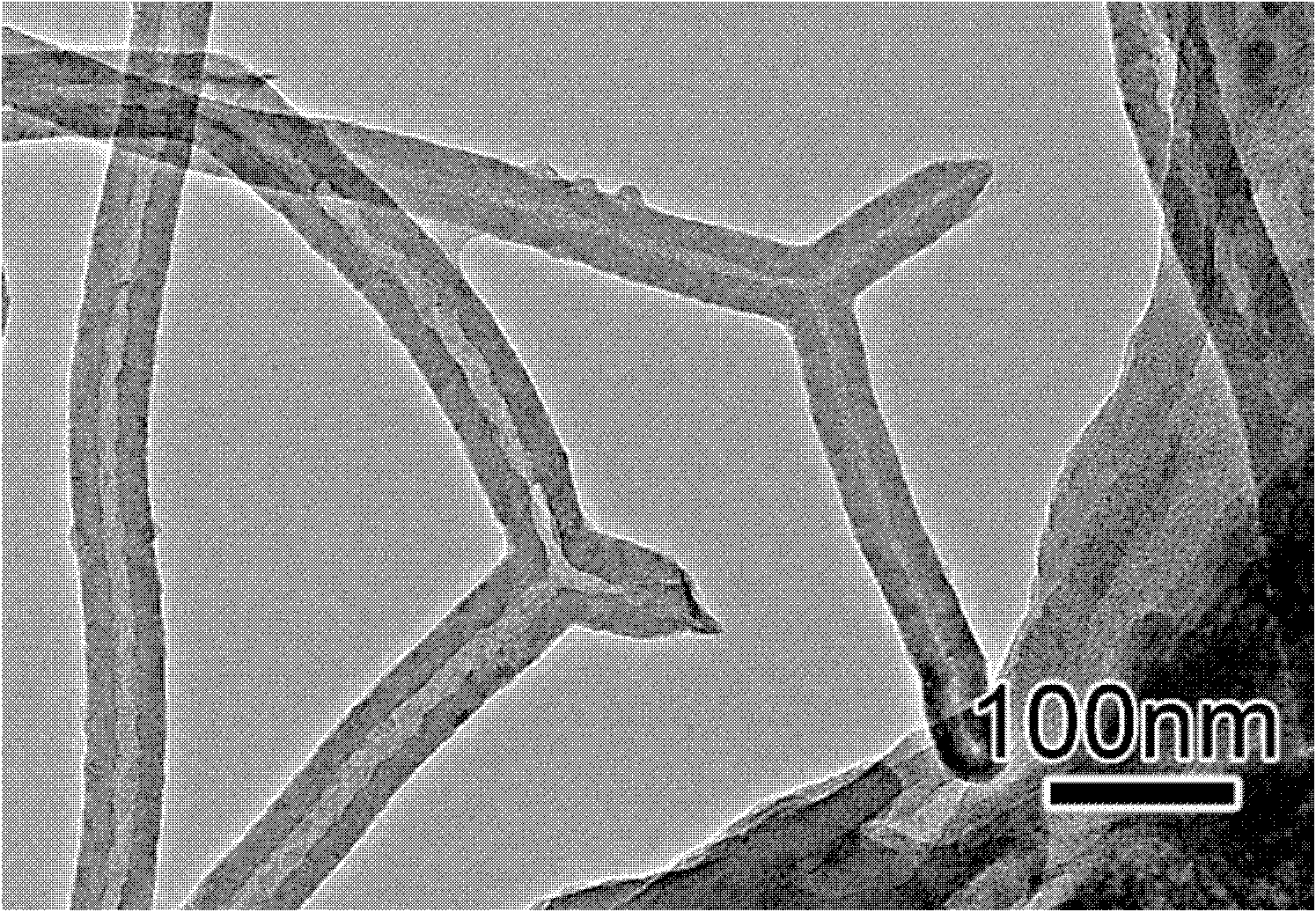

Method for preparing branched carbon nano tube by using dimethyl sulphide as carbon source

A carbon nanotube and dimethyl sulfide technology, applied in nanotechnology and other directions, can solve the problems of low yield of branched carbon nanotubes, long preparation process, complicated equipment, etc., and achieve high yield, high purity, and equipment. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for preparing branched carbon nanotubes using dimethyl sulfide as a carbon source is as follows:

[0031] (1) Dissolving ferrocene powder in dimethyl sulfide to prepare a mixed solution, wherein the mass percentage of ferrocene and dimethyl sulfide is 2.4%;

[0032] (2) Put the mixed solution obtained in step (1) into an Erlenmeyer flask with an air inlet pipe and an air outlet pipe, wherein the air outlet of the air inlet pipe in the Erlenmeyer flask is located at the liquid level of the mixed solution in the Erlenmeyer flask Below, the gas outlet of the gas outlet pipe in the conical flask is above the liquid level of the mixed solution in the conical flask;

[0033] (3) The hydrogen enters the container from the inlet pipe of the conical flask, and the hydrogen and the vapor of the mixed solution in the conical flask are output from the outlet pipe;

[0034] (4) The hydrogen and the vapor of the mixed solution output from the conical flask in step (3) are input into...

Embodiment 2

[0036] A method for preparing branched carbon nanotubes using dimethyl sulfide as a carbon source is as follows:

[0037] (1) Dissolving ferrocene powder in dimethyl sulfide to prepare a mixed solution, wherein the mass percentage of ferrocene and dimethyl sulfide is 4.8%;

[0038] (2) Put the mixed solution obtained in step (1) into an Erlenmeyer flask with an air inlet pipe and an air outlet pipe, wherein the air outlet of the air inlet pipe in the Erlenmeyer flask is located at the liquid level of the mixed solution in the Erlenmeyer flask Below, the gas outlet of the gas outlet pipe in the conical flask is above the liquid level of the mixed solution in the conical flask;

[0039] (3) The hydrogen enters the container from the inlet pipe of the conical flask, and the hydrogen and the vapor of the mixed solution in the conical flask are output from the outlet pipe;

[0040] (4) The hydrogen and the vapor of the mixed solution output from the conical flask in step (3) are input into...

Embodiment 3

[0042] A method for preparing branched carbon nanotubes using dimethyl sulfide as a carbon source is as follows:

[0043] (1) Dissolving ferrocene powder in dimethyl sulfide to prepare a mixed solution, wherein the mass percentage of ferrocene and dimethyl sulfide is 2.9%;

[0044] (2) Put the mixed solution obtained in step (1) into an Erlenmeyer flask with an air inlet pipe and an air outlet pipe, wherein the air outlet of the air inlet pipe in the Erlenmeyer flask is located at the liquid level of the mixed solution in the Erlenmeyer flask Below, the gas outlet of the gas outlet pipe in the conical flask is above the liquid level of the mixed solution in the conical flask;

[0045] (3) The hydrogen enters the container from the inlet pipe of the conical flask, and the hydrogen and the vapor of the mixed solution in the conical flask are output from the outlet pipe;

[0046] (4) The hydrogen and the vapor of the mixed solution output from the conical flask in step (3) are input into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com