Industrial method for producing bio-fertilizer inoculant by utilizing decayed cow dung as raw material

A technology of decomposed cow dung and bio-fertilizer, applied in the preparation of organic fertilizers, organic fertilizers, fertilizer mixtures, etc., can solve difficult problems and achieve the effects of increasing output and quality, low price, and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

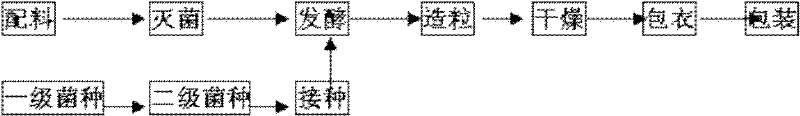

Method used

Image

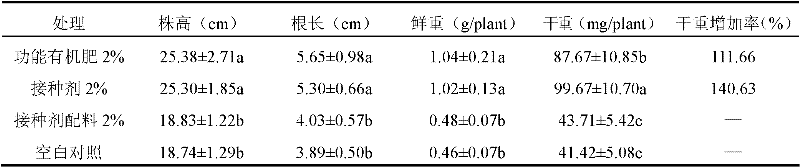

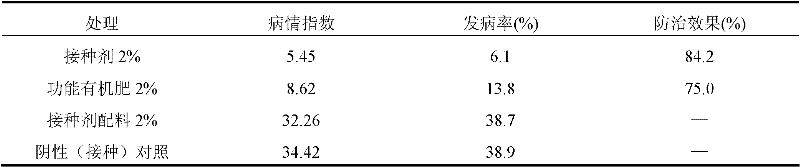

Examples

Embodiment 1

[0030] The production of embodiment 1 Bacillus subtilis disease prevention growth-promoting inoculant

[0031] (1) Take the purified and rejuvenated Bacillus subtilis (Bacillus subtilis; purchased from China Agricultural Culture Collection Center ACCC10167) slant strains, inoculate them into triangular flasks at 31°C, rotate at 50r / min, and ferment for 48 hours to make seed liquid , is a first-class strain; the first-class strain is inoculated into a liquid fermenter (two types of conventional heat-retaining liquid fermenter 70L and 250L) and fermented for 48h, and is a second-class strain. The seed liquid fermentation formula is: beef extract 0.3%, peptone 1.0%, sodium chloride 0.5%, natural pH value.

[0032] (2) 70 parts by weight of decomposed cow dung, 20 parts by weight of field soil, 2 parts by weight of rice bran, 8 parts by weight of soybean meal, the pH value of the mixing material with quicklime is 6.5, add water equivalent to 40% of the total mass of the aforementi...

Embodiment 2

[0052] The production of embodiment 2 phosphorus solubilizing microorganism inoculants

[0053] (1) Take the purified and rejuvenated Bacillus megaterium (Bacillus megaterium; source from China Agricultural Culture Collection Center ACCC10010) slant strains, respectively inoculate them into triangular flasks at 31°C, rotate at 50r / min, and ferment for 48h to make seed liquid. It is a first-class strain; the first-class strain is inoculated into a fermenter and fermented for 48 hours, and it is a second-class strain. The seed liquid fermentation formula is: beef extract 0.3%, peptone 1.0%, sodium chloride 0.5%, natural pH value.

[0054] (2) 65 parts by weight of decomposed cow dung, 25 parts by weight of field soil, 2 parts by weight of rice bran, 8 parts by weight of soybean meal, the pH value of the mixing material with quicklime is 6.0, add water equivalent to 40% of the total mass of the aforementioned raw materials, and mix well , pass steam above 100°C, and sterilize fo...

Embodiment 3

[0062] The production of embodiment 3 silicate microbial inoculants

[0063] (1) Take the purified and rejuvenated bacillus mucilaginosus (Bacillus mucilaginosus; source from China Agricultural Culture Collection Center ACCC10013) slant strains, inoculate them into triangular flasks and ferment for 48 hours at 31°C to make seed liquid, which is a first-class strain ; The primary bacterial strain is inoculated into the fermenter and fermented for 48 hours, which is a secondary bacterial strain. The seed liquid fermentation formula is: beef extract 0.3%, peptone 1.0%, sodium chloride 0.5%, calcium carbonate 0.1%, natural pH value.

[0064] (2) 60 parts by weight of decomposed cow dung, 25 parts by weight of field soil, 5 parts by weight of rice bran, 8 parts by weight of soybean meal, 2 parts by weight of talcum powder. % water, stir evenly, pass steam above 100°C, and sterilize for 2 hours.

[0065] (3) Insert the secondary bacterial species in (1) into the sterilized solid m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com