Method for preparing PDLC (Polymer Dispersed Liquid Crystal) by epoxy resin ultraviolet photoinduced cationic polymerization

A cationic polymerization, epoxy resin technology, applied in liquid crystal materials, chemical instruments and methods, optics, etc., can solve the problems of long polymerization temperature and polymerization time, insufficient adhesion, increase product cost, etc., and achieve good chemical corrosion resistance. , The effect of improving optoelectronic properties and improving thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

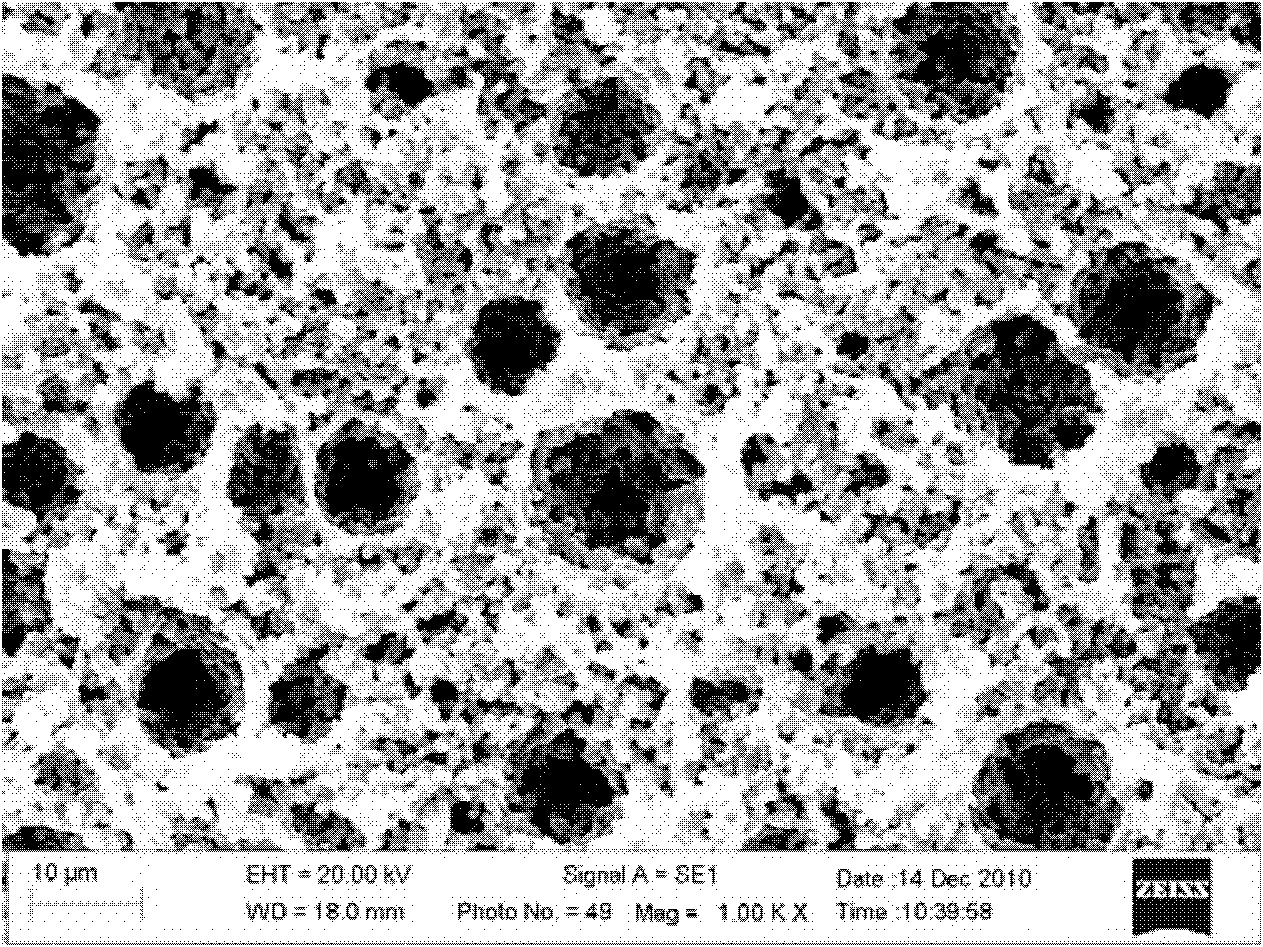

Embodiment 1

[0024] The ultraviolet light polymerizable epoxy monomer selected is polyethylene glycol diglycidyl ether (EGDE, =3 and 10), two monomers with different chain lengths were mixed uniformly at a mass ratio of 10:1 to form a polymerized monomer system, and the selected nematic liquid crystal was SLC1717 (T NI =365.2K, n o =1.519, n e =1.720), and the mass ratio of the mixed monomer system used and the nematic liquid crystal is 1:1, and the isotropic liquid is formed at room temperature (20°C). A cationic photoinitiator (UVI-6976) was added at 1.0% of the total mass, and glass beads with a diameter of 5 μm were added to control the thickness of the PDLC film. The content of glass beads was 0.5% of the total mass of the mixed system. After mixing liquid crystal, ultraviolet light polymerizable epoxy monomer, cationic photoinitiator and glass microspheres evenly, it is coated in the middle of two plastic films coated with indium tin oxide (ITO) transparent conductive film, and is...

Embodiment 2

[0028] The UV-polymerizable epoxy monomer selected is (a) polyethylene glycol diglycidyl ether (EGDE, =3); (b) bisphenol F epoxy resin (DGEBF), the two monomers are mixed uniformly at a mass ratio of 10:1 to form a polymerized monomer system, and the nematic liquid crystal selected is SLC1717 (T NI =365.2K, n o =1.519, n e=1.720), and the mass ratio of the mixed monomer system used and the liquid crystal is 1:1, and the isotropic liquid is formed at room temperature (20°C). Add cationic photoinitiator (UVI-6976) to 5.0% of the total mass, and add glass beads with a diameter of 12 μm to control the thickness of the PDLC film. The content of glass beads is 10% of the total mass of the mixed system. After mixing liquid crystal, ultraviolet light polymerizable epoxy monomer, cationic photoinitiator and glass microspheres evenly, it is coated in the middle of two plastic films coated with indium tin oxide (ITO) transparent conductive film, and is formed by rolling. film. The f...

Embodiment 3

[0031] The UV-polymerizable epoxy monomer selected is (a) polyethylene glycol diglycidyl ether (EGDE, =3); (b) Trimethylolpropane Triglycidyl Ether (TMPTTE) (c) Pentaerythritol Glycidyl Ether (PTTE) The above monomers were mixed uniformly at a mass ratio of 20:1:1 to form a polymerized monomer system. The nematic liquid crystal is selected as SLC1717 (T NI =365.2K, n o =1.519, n e =1.720), and the mass ratio of the mixed monomer system used and the liquid crystal is 1:1, and the isotropic liquid is formed at room temperature (20°C). Add cationic photoinitiator (UVI-6976) to 10% of the total mass, and add glass beads with a diameter of 20 μm to control the thickness of the PDLC film. The content of glass beads is 5.5% of the total mass of the mixed system. After mixing liquid crystal, ultraviolet light polymerizable epoxy monomer, cationic photoinitiator and glass microspheres evenly, it is coated in the middle of two plastic films coated with indium tin oxide (ITO) transpa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com