Method for producing food ingredient rich in nitrite and flavonoid by use of celery leaves

A technology of nitrite and food ingredients, applied in the field of deep processing of vegetables, can solve the problems of affecting the economic interests of vegetable farmers, environmental pollution, increasing garbage removal and disposal costs, etc., and achieve the effect of improving comprehensive utilization capacity, no environmental pollution, and reducing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

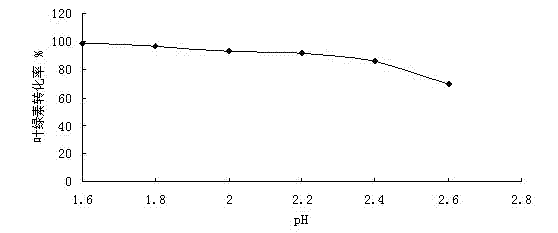

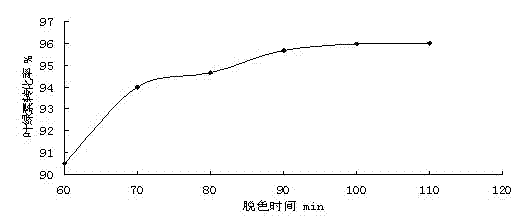

[0026] Embodiment 1 decolorization condition optimization

[0027] In the production process of celery powder, in order to add celery powder to meat products without affecting the color of meat products, the green color of celery must be removed. Taking the chlorophyll conversion rate combined with the sensory evaluation as the investigation index, the optimal process parameters of color treatment were obtained through the optimization of single factor and orthogonal experiments. The single factor experiment of decolorization temperature, decolorization time, pH and soaking time is as follows:

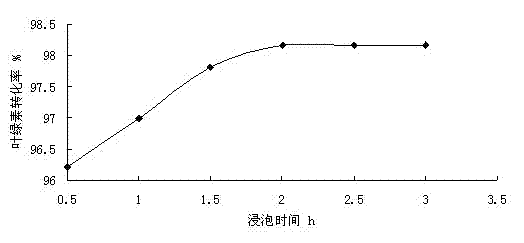

[0028] (1) Influence of soaking time of citric acid solution on decolorization effect

[0029] Soak the washed celery leaves in a citric acid solution with a pH of 1.8 at a material-to-liquid ratio of 1:5, and place the raw materials soaked in the citric acid solution in an incubator with a temperature of 80°C and a humidity of ≥90% for 100 minutes, and observe Effect of soaking time...

Embodiment 2

[0045] The determination of embodiment 2 microbial transformation conditions

[0046] According to the optimal growth temperature of Staphylococcus carnosus and Staphylococcus xylosus, combined with the optimal conditions for the production of nitrate reductase by these two bacteria, the optimal temperature for microbial transformation was determined to be 38°C. Staphylococcus carnosus and Staphylococcus xylosus were inoculated in the slurry at a ratio of 1:1, and the inoculum volume of the two strains was 2×10 7 cfu / g slurry, incubate at 38°C for 6 hours to convert nitrate into nitrite. The conversion rate of nitrate in this process can reach 95%, and the process conditions have no obvious influence on flavonoids.

[0047] Staphylococcus meatus ( Staphylococcus camosus ), Staphylococcus xylosus ( Staphylococcus xylosus ) are commonly used strains, see China Microorganism Strains Network (http: / / www.mum800.com / ) for details, and any of the strains listed on the Internet c...

Embodiment 3

[0048] Embodiment 3 Determination of drying conditions

[0049] Spread the celery pulp transformed by microorganisms on the material tray, the thickness of the stacked tray is ≤1cm, and dry at 100°C, hot air at normal pressure, and vacuum drying at a vacuum degree of -0.1Mpa, and a temperature of 80°C, and dry until the moisture content is ≤5% , with drying time and the loss rate of flavonoids and nitrous acid as the main indicators to evaluate the drying effect, the research found that the drying time of hot air drying and vacuum drying was 4h and 5.5h respectively, and the average loss of flavonoids was 8.2% and 7.5%, Nitrite loss was not obvious. By contrast, choose 100 ℃ normal pressure hot air drying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com