Method for preparing crosslinking hyaluronic acid gel

A technology of cross-linked hyaluronic acid and hyaluronic acid, which is applied in the field of pharmacy, can solve the problems of reduced viscoelasticity of cross-linked hyaluronic acid gel, unsatisfactory maintenance time, and unsatisfactory filling effect, etc., so as to broaden the use and application effect, high molecular weight, long retention time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

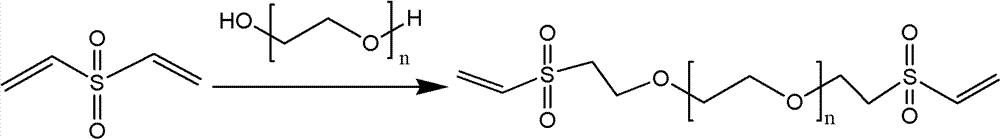

[0036] Add 0.22g of diethylene glycol to 4ml of 0.02M NaOH aqueous solution, heat to reflux for 0.5h to make a diethylene glycol alkali solution, and cool to room temperature;

[0037] Add 0.05g of divinyl sulfone into the polyethylene glycol alkali solution, then raise the temperature of the solution to 35°C to initiate the reaction, cool with an ice bath to keep the temperature at about 60°C, stop the heat release, and then heat to 80°C for 5 minutes , cooled to room temperature, to obtain a viscous product, add 10ml of water to dissolve;

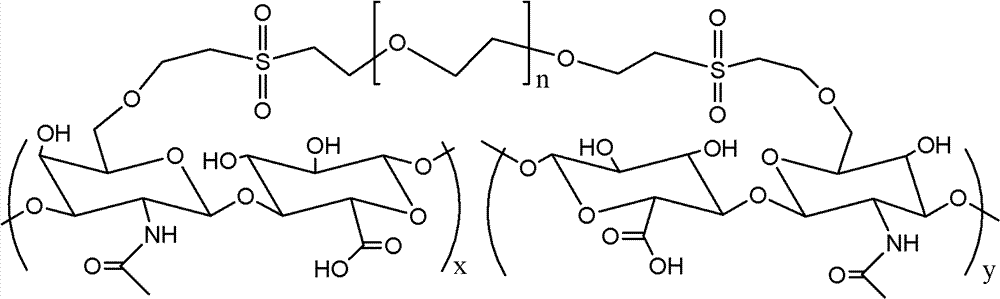

[0038] Add 1g of sodium hyaluronate dry powder with a molecular weight of 1 million to 25ml of 0.2M NaOH aqueous solution, stir to dissolve, add to the above product, stir at room temperature for 2 to 3 hours to form a cross-linked sodium hyaluronate gel;

[0039] Then add 160ml of PBS buffer solution (pH7.0) to swell for 24 or 48 hours, remove the buffer, rinse with normal saline and soak until the gel is transparent and homogeneous;

...

Embodiment 2

[0042] Add 1.64g polyethylene glycol 400 to 4ml 0.02M NaOH aqueous solution, heat to reflux for 0.5h to make polyethylene glycol alkali solution, and cool to room temperature;

[0043] Add 0.05g of divinyl sulfone into the polyethylene glycol alkali solution, then raise the temperature of the solution to 35°C to initiate the reaction, cool with an ice bath to keep the temperature at about 60°C, stop the heat release, and then heat to 80°C for 5 minutes , cooled to room temperature, to obtain a viscous product, add 20ml of water to dissolve;

[0044] Add 1g of sodium hyaluronate dry powder with a molecular weight of 1 million to 25ml of 0.2M NaOH aqueous solution, stir to dissolve, add to the above product, stir at room temperature for 2 to 3 hours to form a cross-linked sodium hyaluronate gel;

[0045] Then add 160ml of PBS buffer solution (pH7.0) to swell for 24 or 48 hours, remove the buffer, rinse with normal saline and soak until the gel is transparent and homogeneous;

...

Embodiment 3

[0048] Add 2.52g polyethylene glycol 600 into 4ml 0.02M NaOH aqueous solution, heat to reflux for 0.5h to make polyethylene glycol alkali solution, and cool to room temperature;

[0049] Add 0.05g of divinyl sulfone into the polyethylene glycol alkali solution, then raise the temperature of the solution to 35°C to initiate the reaction, cool with an ice bath to keep the temperature at about 60°C, stop the heat release, and then heat to 80°C for 5 minutes , cooled to room temperature, to obtain a viscous product, add 25ml of water to dissolve;

[0050] Add 1g of sodium hyaluronate dry powder with a molecular weight of 300,000 to 25ml of 0.2M NaOH aqueous solution, stir to dissolve, add to the above product, stir at room temperature for 2 to 3 hours to form a cross-linked sodium hyaluronate gel;

[0051] Then add 160ml of PBS buffer solution (pH7.0) to swell for 24 or 48 hours, remove the buffer, rinse with normal saline and soak until the gel is transparent and homogeneous;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com