Composite mesoporous film of PETP (polyethylene glycol terephthalate) as well as preparation method and application thereof

A technology of polyethylene terephthalate and ethylene glycol phthalate film, which is applied in the field of film materials, can solve the problems of high cost, poor film flexibility, easy cracking, etc., and achieve good acid and alkali resistance , good flexibility and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

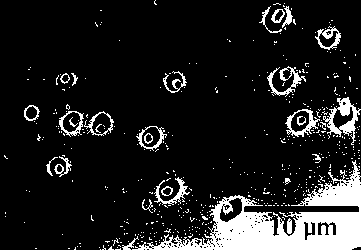

Image

Examples

Embodiment 1

[0049] Preparation of polyethylene terephthalate composite mesoporous membrane assembled with mesoporous materials with a pore diameter of 3.0 nm

[0050] Mix 7.68g of absolute ethanol, 11.57g of tetraethyl orthosilicate and 1ml of hydrochloric acid (2.8mmol / L), stir slowly, condense and reflux for 90min in a water bath at 60°C; then add 15g of absolute ethanol, 1.52 g hexadecyltrimethylammonium bromide (CTAB), 4ml hydrochloric acid (55mmol / L) mixed solution, stirred and reacted at room temperature 25°C for 30min, cooled to room temperature 25°C to obtain a precursor containing CTAB liquid. Using a suction filtration pump (manufactured by Shanghai Mosu Scientific Equipment Co., Ltd., HPD-25 oil-free filtration pump) and a standing suction filtration device in the laboratory (1000ml suction filtration bottle), divide 4ml of the precursor solution (containing CTAB) into two (2ml each time) filter through a polyethylene terephthalate membrane (produced by Shanghai Haoxia Nuclear...

Embodiment 2

[0059] 0.04 mg / ml rhodamine B aqueous solution and 0.04 mg / ml horseradish peroxidase aqueous solution were respectively placed in the molecular transfer device equipped with the polyethylene terephthalate composite mesoporous membrane of the present invention. The photo of molecular transfer of final rhodamine B aqueous solution and 0.04 mg / ml horseradish peroxidase aqueous solution is attached Figure 6 , as shown in 7. from Figure 6 , 7 It can be seen that the red rhodamine dye molecule can pass through the polyethylene terephthalate composite mesoporous membrane from one end to the other end, but the light brown horseradish peroxidase molecule cannot pass through from one end. The polyethylene terephthalate composite mesoporous membrane transmits to the other end.

[0060] Using UV-visible spectrophotometry (Carry100 UV-visible spectrophotometer, Varian Company, USA) to investigate the rhodamine B dye molecules (molecular size3.0nm) in the aqueous solution were assemble...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com