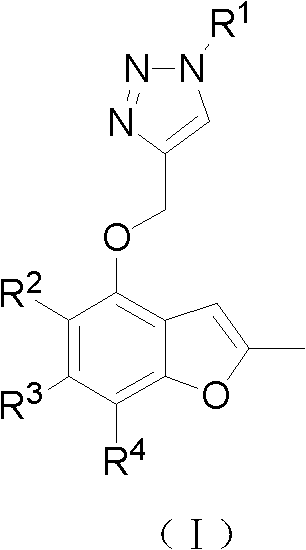

Triazole heterocycle-containing 2-methyl benzofuran compound, and preparation and application thereof

A compound, the technology of methylbenzene, applied in the field of 2-methylbenzofuran compounds, can solve the problems of impossibility and time-consuming, and achieve the effect of improving efficiency, increasing reaction yield, and convenient operation of synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1: the preparation of selenium resin load (IV-1)

[0043] The reaction formula is as follows:

[0044]

[0045] Under a nitrogen atmosphere, 0.8 grams of 1.25mmol / g (1.00mmol) polystyrene-loaded selenium bromide resin (II) in 30mL CHCl 3 Soak in the middle for 12 hours, then add 1.79g (5.0mmol) compound shown in formula (III-1), 0.580g (5.0mmol) tetramethylethylenediamine, stir and react at 60°C for 4.0 hours, filter the reaction solution, filter The cake was successively filled with 20mL of water, 20mL of tetrahydrofuran, 20mL of tetrahydrofuran and water mixture (volume ratio of 1:1), 20mL of tetrahydrofuran, 20mL of tetrahydrofuran and water mixture (volume ratio of 1:1), 20mL of tetrahydrofuran, 20mL of chloroform, 20mL Washed with dichloromethane, dried under vacuum at 45° C. for 6 hours to obtain 1.076 g of the selenium resin supported substance represented by formula (IV-1).

Embodiment 2

[0046] Embodiment 2: Preparation of selenium resin load (V-1)

[0047] The reaction formula is as follows:

[0048]

[0049] Under a nitrogen atmosphere, 1.076 g of the selenium resin load (IV-1) obtained in Example 1 (the amount of the material loaded with selenium is 1.0 mmol) was soaked in 30 mL of chloroform for 5 hours, and 0.75 mL (8.0 mmol) of alkyne was added thereto. Propyl bromide, 1.12g (8.0mmol) potassium carbonate, reacted at 60°C for 8.0 hours, filtered the reaction solution, and washed the filter cake with 30mL of water, 30mL of tetrahydrofuran, 30mL of tetrahydrofuran and water mixture (volume ratio: 1:1), Wash with 30mL tetrahydrofuran, 30mL tetrahydrofuran and water mixture (1:1 volume ratio), 30mL tetrahydrofuran, 30mL chloroform, and 30mL dichloromethane, and vacuum-dry at 40°C for 6 hours to obtain the selenium resin-loaded solution shown in formula (V-1). Material 1.110g.

Embodiment 3

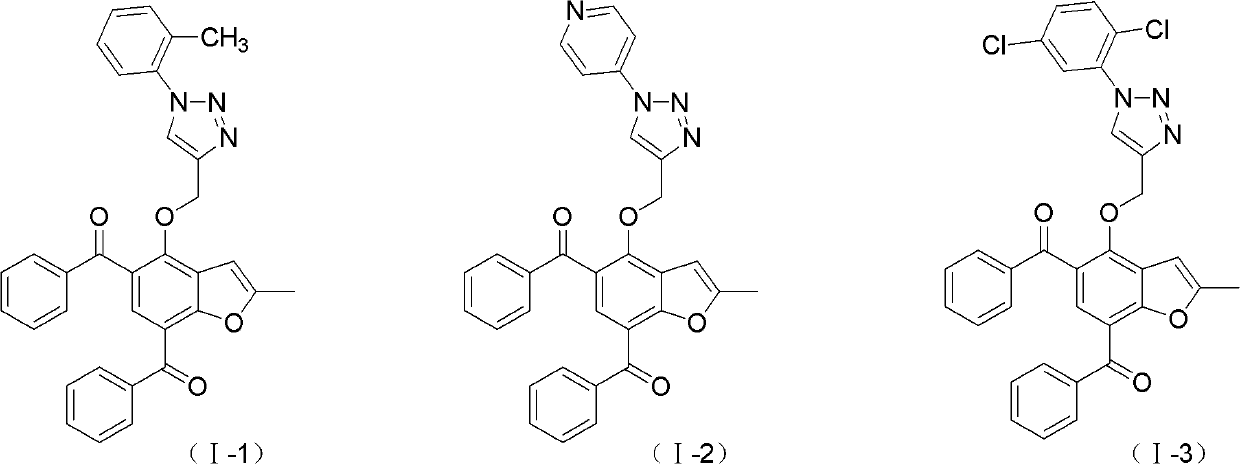

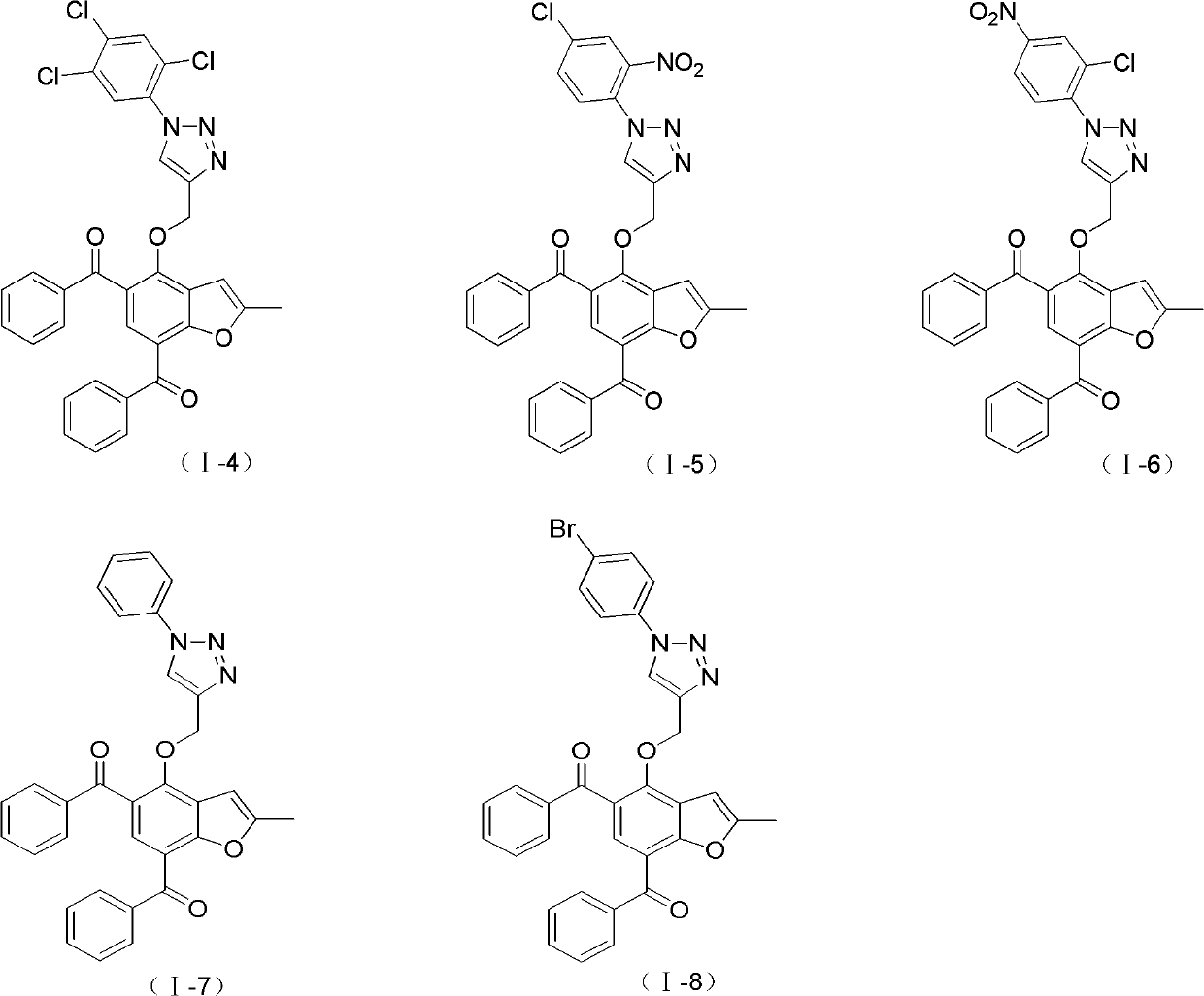

[0050] Embodiment 3: The preparation reaction formula of the 2-methylbenzofuran compound (I-1) containing triazole heterocycle is as follows:

[0051]

[0052]

[0053] (1) Under a nitrogen atmosphere, 0.4g (3.0mmol) 2-methylphenyl azide (VI-1) was added to the selenium resin load prepared by the method of Example 2 soaked in 30mL dimethyl sulfoxide for 5 hours in advance (V-1) 1.110g (the amount of selenium-loaded substance is 1.0mmol), then add 5mL water, finally add 0.2g (0.8mmol) copper sulfate pentahydrate and 0.8g vitamin C, stir, and react at 35°C for 10 hours , to end the reaction, the reaction solution was filtered, and the filter cake was successively washed with 40mL of water, 40mL tetrahydrofuran, 40mL tetrahydrofuran and water mixed solution (volume ratio is 1: 1), 40mL tetrahydrofuran, 40mL tetrahydrofuran and water mixed solution (volume ratio is 1: 1) ), 40mL tetrahydrofuran, 40mL chloroform, 40mL dichloromethane, and vacuum-dried at 40° C. for 6 hours to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com