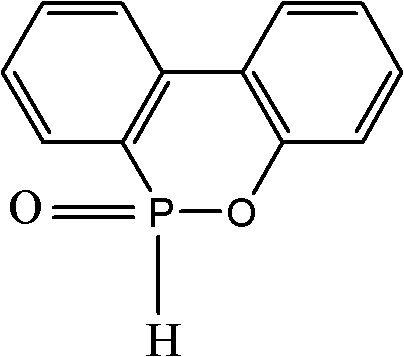

Synthesis and purification process for DOPO

A process, the technology of phosphorus trichloride, applied in the field of flame retardants, can solve the problems of high impurity content, high reaction temperature, and difficulty in industrialization, and achieve the effects of short cyclization time, high purity, and reduced difficulty in process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

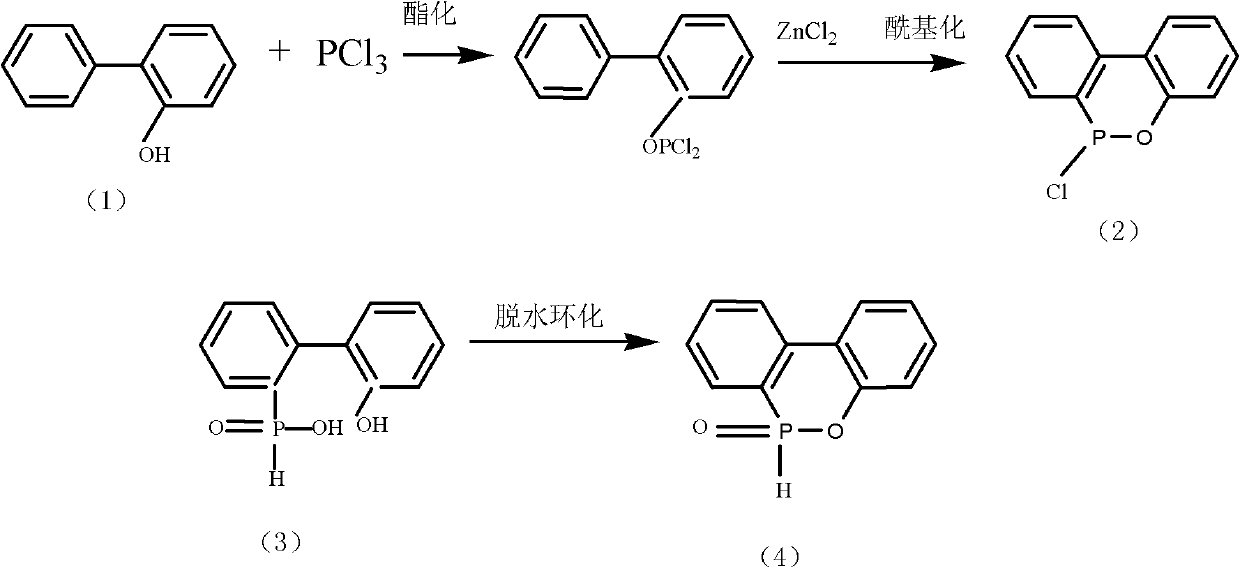

Method used

Image

Examples

Embodiment 1

[0025] Step 1, the synthesis of 6-chloro-(6 hydrogen)-diphenyl(c,e)[1,2]-phosphaphenanthrene: using anhydrous zinc chloride as a catalyst, using o-phenylphenol and phosphorus trichloride As raw materials, o-phenylphenol, anhydrous zinc chloride and phosphorus trichloride were sequentially added to the reactor, heated to 175°C at a heating rate of 3°C / min and reacted for 4 hours to generate 6-chloro-(6 hydrogen) -diphenyl (c, e) [1,2]-phosphaphenanthrene liquid; the mol ratio of the phosphorus trichloride and o-phenylphenol is 1.2:1, and the consumption of anhydrous zinc chloride is o-phenylphenol 0.5% of the mass; among them, phosphorus trichloride is added in the reactor three times, first add 70% of the total amount of phosphorus trichloride at room temperature, and then add 70% of the total amount of phosphorus trichloride when the reaction solution is heated to 105°C 20%, and then add the remaining phosphorus trichloride when the reaction solution is heated to 155°C;

[0...

Embodiment 2

[0031] This example is the same as Example 1, except that the alcoholic organic solvent used is methanol or isopropanol, the aromatic organic solvent used is benzene, toluene, chlorobenzene or dichlorobenzene, and the metal salt catalyst used is Magnesium sulfate, aluminum sulfate, iron sulfate, zinc sulfate, chromium sulfate or manganese sulfate, or magnesium chloride, aluminum trichloride, zinc chloride, chromium chloride or manganese chloride, the aliphatic hydrocarbon organic solvent used is hexane, n-pentane or isopentane.

[0032] In this embodiment, phosphorus trichloride is added in three times, the heating rate is fast, the reaction temperature is low, and the occurrence of side reactions is effectively reduced. phenyl-2-phosphinic acid) for dehydration and cyclization, the cyclization time is short, the operation is simple, and the production efficiency is improved. The prepared DOPO has a purity of ≥99%, a yield of ≥88%, and a melting point of 117.2°C to 118.6°C. E...

Embodiment 3

[0034]Step 1, the synthesis of 6-chloro-(6 hydrogen)-diphenyl(c,e)[1,2]-phosphaphenanthrene: using anhydrous zinc chloride as a catalyst, using o-phenylphenol and phosphorus trichloride As raw materials, o-phenylphenol, anhydrous zinc chloride and phosphorus trichloride were added to the reactor in sequence, heated to 158°C at a heating rate of 0.25°C / min and reacted for 8 hours to generate 6-chloro-(6 hydrogen) -diphenyl (c, e) [1,2]-phosphaphenanthrene liquid; the mol ratio of the phosphorus trichloride and o-phenylphenol is 1.5:1, and the consumption of anhydrous zinc chloride is o-phenylphenol 2.0% of the mass; wherein, phosphorus trichloride is added into the reactor in three times, first adding 85% of the total amount of phosphorus trichloride at room temperature, and then adding 85% of the total amount of phosphorus trichloride when the reaction solution is heated to 130°C 10%, and then add the remaining phosphorus trichloride when the reaction solution is heated to 140...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com