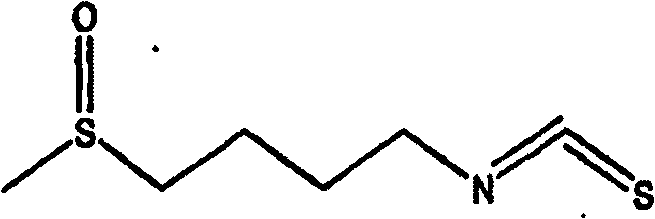

Method for preparing sulforaphane

A technology of radish and radish, applied in the direction of organic chemistry, etc., can solve the problems of complex and cumbersome process, difficult to realize industrialization, and easy destruction of radish, so as to achieve increased content and purity, high selectivity, and high degree of industrialization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Grind radish seeds, take 20kg, add to the extraction tank, add 40kg of hydrochloric acid aqueous solution (pH5), heat to 50°C for 60 minutes, heat up to 80°C quickly, after 30 minutes, add 120kg of water, stir and extract for 2 hours, and filter out the liquid , add 100kg of water to extract, combine the two liquids, filter and add AB-8 macroporous resin for adsorption, wash neutral with water, take 6 times the amount of 50% ethanol solution to elute, collect the eluate, add hollow cellulose with a molecular weight cut-off of 400 Membrane nanofiltration, add appropriate amount of water for dialysis, collect the passing liquid and then add it to the reverse osmosis membrane to concentrate, collect the concentrated liquid and add an equal volume of dichloromethane to extract, extract 4 times, collect the extract to recover the reagent under reduced pressure, 9g oily rapatin, after The content detected by HPLC is 75.6%.

Embodiment 2

[0025] Grind radish seeds, take 20kg, add to the extraction tank, add 60kg of sulfuric acid aqueous solution (pH4), heat to 45°C for 60 minutes, then rapidly heat up to 80°C, after 30 minutes, add 100kg of water, stir and extract for 2 hours, and filter out the liquid , add 100kg of water to extract, combine the two liquids, filter and add D101 macroporous resin for adsorption, wash neutral with water, take 5 times the amount of 70% ethanol solution for elution, collect the eluate, add hollow cellulose membrane with a molecular weight cut-off of 500 Filtrate, add appropriate amount of water for dialysis, collect the passing liquid, add reverse osmosis membrane to concentrate, collect the concentrated liquid and add 2 times the volume of dichloromethane for extraction, extract 3 times, collect the extract and recover the reagent under reduced pressure, 11g oily rapatin, after high-efficiency The liquid detection content was 70.1%.

Embodiment 3

[0027] Grind radish seeds, take 20kg, add to the extraction tank, add 60kg of sulfuric acid aqueous solution (pH4), heat to 45°C for 60 minutes, heat up to 80°C quickly, after 30 minutes, add 100kg of water, stir and extract for 2 hours, and filter out the liquid , add 100kg of water to extract, combine the two liquids, filter and add HPD100 macroporous resin for adsorption, wash neutral with water, take 5 times the amount of 60% ethanol solution for elution, collect the eluate, add hollow cellulose membrane with a molecular weight cut-off of 400 Filtrate, add appropriate amount of water for dialysis, collect the passing liquid, add reverse osmosis membrane to concentrate, collect the concentrated liquid and add 2 times the volume of dichloromethane for extraction, extract 3 times, collect the extract and recover the reagent under reduced pressure, 6g oily rapatin, after high-efficiency The liquid detection content was 71.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com