Environment-friendly preparation method for high-ester catechin tea polyphenol

A technology of tea polyphenols and catechins, which is applied in the field of green preparation of high-ester-type catechin-tea polyphenols, can solve the problem of low content of ester-type catechins, and achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

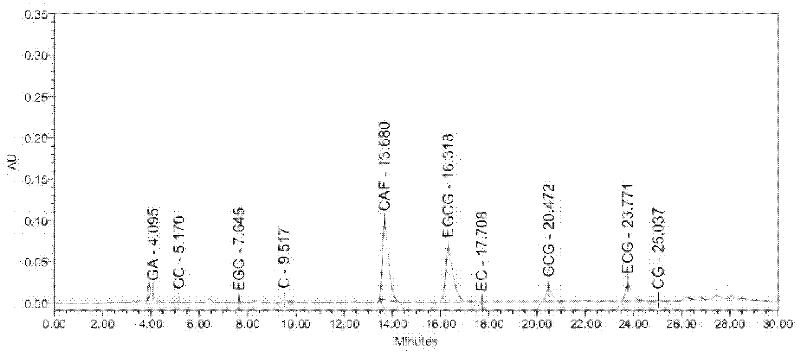

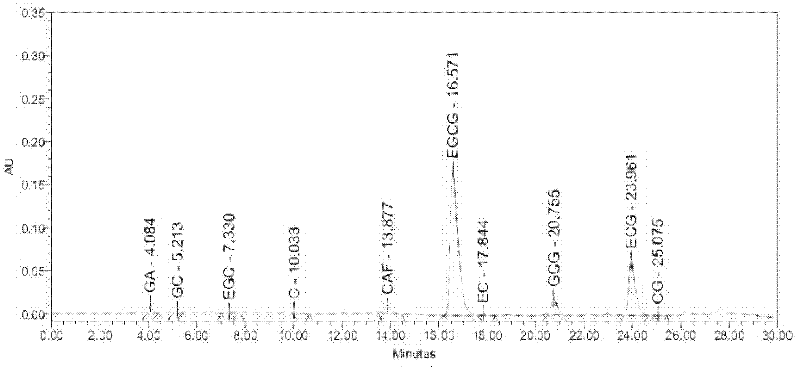

Image

Examples

Embodiment 1

[0015] Weigh 50g of tea leaves, add 500ml of deionized water (80°C) to extract for 45 minutes, take out the extract, then add an equal volume of deionized water (80°C) to extract for 45 minutes, combine the extracts, pass through 200 mesh -400 Purpose Suction filtration with filter cloth, treatment with 0.2um ceramic membrane to obtain tea polyphenol microfiltrate, and then concentrated by RO membrane to obtain tea polyphenol membrane concentrate.

[0016] Fill the styrene-type medium polar resin with a diameter of 16mm and a length of In a 600mm chromatography column, the volume of the packed column bed is 80ml, and the resin is rinsed with 95% ethanol and water in sequence until the column bed is balanced. At room temperature, load the tea polyphenol film concentrate onto the resin column, rinse with 1.5BV of deionized water, 2BV of food grade ethanol: deionized water = 8:2 elution solvent, and the rinsing speed is 2BV / h, collect and combine the eluate, vacuum evaporation, ...

Embodiment 2

[0019] Weigh 50g of tea leaves, add 500ml of deionized water (80°C) to extract for 45 minutes, take out the extract, then add an equal volume of deionized water (80°C) to extract for 45 minutes, combine the extracts, pass through 200 mesh -400 Purpose Suction filtration with filter cloth, treatment with 0.2um ceramic membrane to obtain tea polyphenol microfiltrate, and then concentrated by RO membrane to obtain tea polyphenol membrane concentrate.

[0020] Fill the styrene-type medium-polarity resin with a diameter of 16 mm, In a chromatographic column with a length of 600 mm, the volume of the packed column bed is 80 ml, and the resin is sequentially washed with 95% ethanol and water until the column bed is balanced. At room temperature, load the tea polyphenol film concentrate onto the resin column, rinse with 1BV of deionized water, 2BV of food grade ethanol: deionized water = 8:2 mixed elution solvent, and the washing speed is 2BV / h, collect and combine the eluate, vacuum...

Embodiment 3

[0023] Weigh 250g of tea leaves, add 2000ml deionized water (90°C) to extract for 35min, take out the extract, then add an equal volume of deionized water (90°C) to extract for 35min, combine the extracts, pass through 200 mesh -400 Purpose Suction filtration with filter cloth, treatment with 0.2um ceramic membrane to obtain tea polyphenol microfiltrate, and then concentrated by RO membrane to obtain tea polyphenol membrane concentrate.

[0024] Fill the styrene-type medium-polarity resin with a diameter of 36mm and a length of In a 1000mm chromatographic column, the volume of the packed column bed is 700ml, and the resin is sequentially washed with 95% ethanol and water until the column bed is balanced. At room temperature, load the tea polyphenol film concentrate onto the resin column, rinse with 1.5BV of deionized water, 2BV of food grade ethanol: deionized water = 8:2 elution solvent, and the rinsing speed is 2BV / h, collect and combine the eluate, vacuum evaporation, conc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Membrane pore size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com