Photonic quasicrystal graph sapphire substrate and manufacturing method thereof and light emitting diode and preparation method thereof

A sapphire substrate and light-emitting diode technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of increasing the thermal resistance of LED chips, demanding photolithography technology, and limiting LED optical power, etc., to improve leakage characteristics and Improvement of internal quantum efficiency and light extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

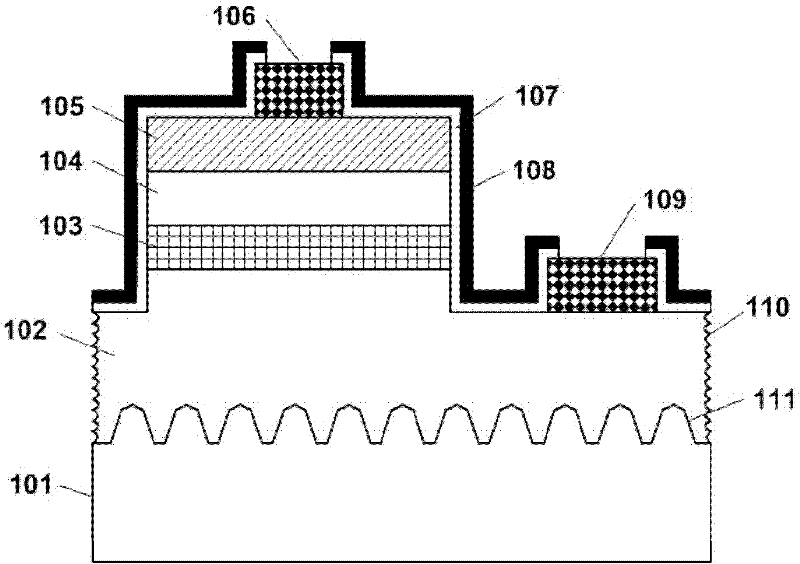

[0042] Such as figure 1 As shown, the light emitting diode structure provided in this embodiment includes: N-type GaN 102 is formed on a sapphire substrate 101; a multi-quantum well layer 103 is formed on N-type GaN 102; P-type GaN 104 is formed on On the multi-quantum well layer 103; the ITO transparent conductive layer 105 is formed on the P-type gallium nitride 104; the P electrode 106 is formed on the ITO transparent conductive layer 105; the N electrode 109 is formed on the N-type gallium nitride 102 The first passivation layer 107 of silicon nitride is formed on the mesa and sidewall of the light-emitting diode; the second passivation layer 108 of silicon nitride oxide is formed on the first passivation layer 107 of silicon nitride; the microstructure 110 of the sidewall is formed on On the sidewall of the N-type gallium nitride 102 ; the quasi-photonic crystal pattern structure 111 is formed on the single crystal sapphire substrate 101 .

[0043] A method of manufactu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Lattice constant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com