Method for preparing environment barrier coating at low temperature

An environmental barrier coating, low temperature technology, applied in the field of low temperature preparation of environmental barrier coatings, can solve problems such as damage, and achieve the effects of easy diffusion, no equipment, and good performance guaranteed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1. Add 40wt% BSAS powder to the polysiloxane precursor, and then mix 5wt% boric acid as a sintering aid. Ball mill for 30 minutes using a vibrating ball mill.

[0030] 2. Brush the mixed slurry onto the surface of the C / SiC sample and cure at 120°C for 10 minutes.

[0031] 3. Pass argon as a protective gas in a vacuum tube furnace, and heat-treat at 1200°C for 2 hours. A dense BSAS coating can be obtained.

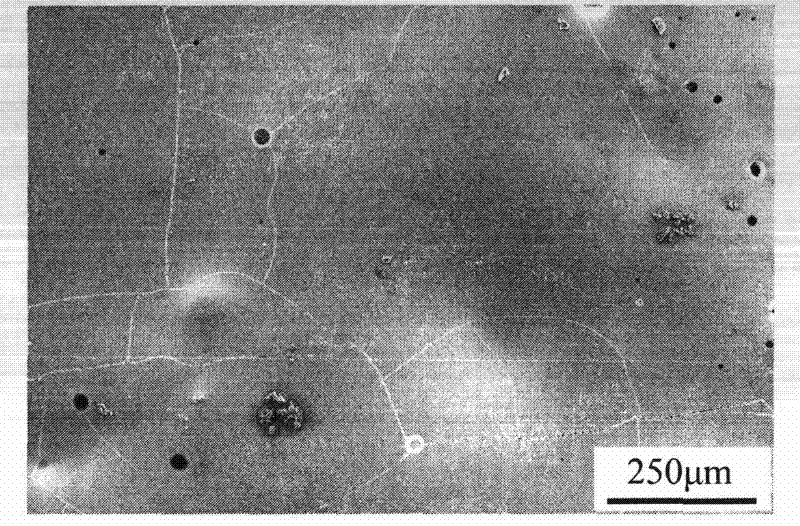

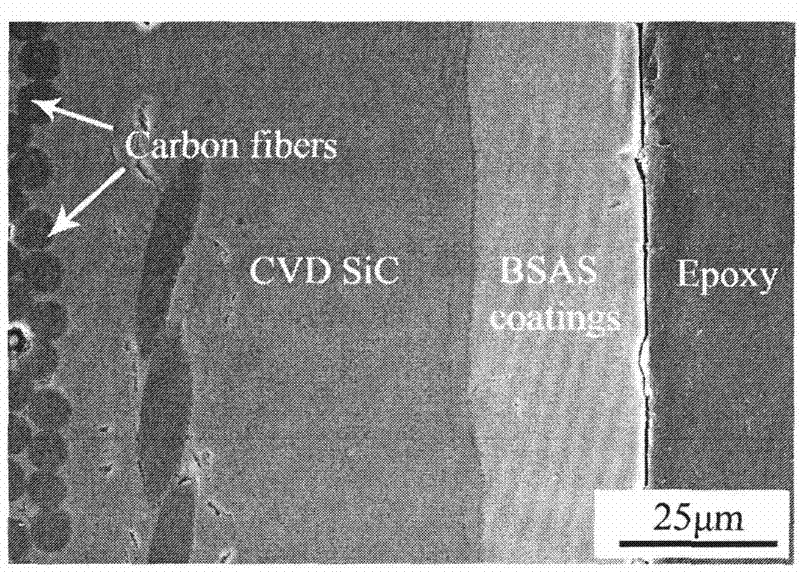

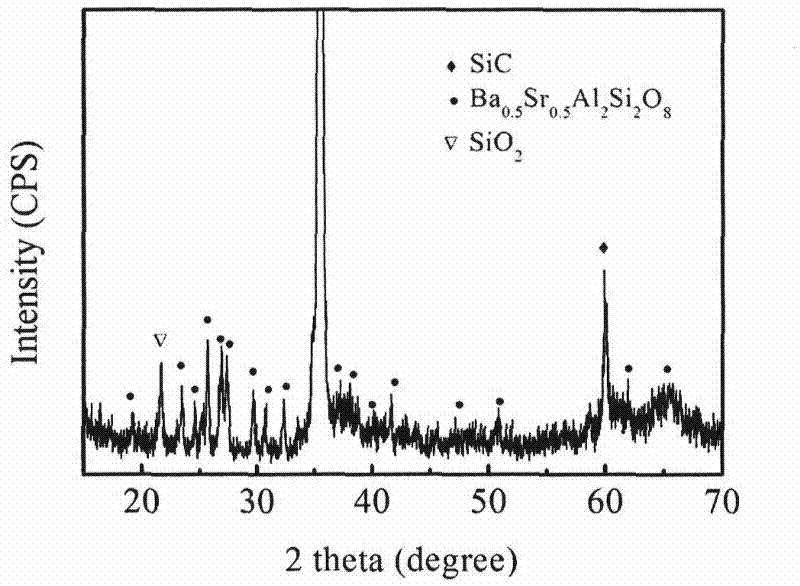

[0032] 4. The performance assessment of the coating is carried out in the water-oxygen corrosion device. The conditions of the whole water-oxygen corrosion experiment are as follows: the temperature in the furnace is 1250 ° C, the atmosphere is 50% H 2 O-50%O 2 , the gas flow rate is 8.5×10 -4 m / s (the flow rate is an estimated value at room temperature), the pressure is 1 atm, and the entire water-oxygen corrosion time is 200 hours. From the cross-section of the sample after water and oxygen corrosion, it can be seen that the coated sample, the C fibers in th...

Embodiment 2

[0035] Example 2: Mixing Sc with polyazide silane as a precursor 2 Si 2 o 7 Powder preparation slurry, using Li 2 CO 3 Preparation of Sc at 1250°C as a sintering aid 2 Si 2 o 7 Environmental barrier coatings.

[0036]1. Add 70wt% Sc 2 Si 2 o 7 The powder was added to the precursor of polyazide silane, and then mixed with 5wt% Li 2 CO 3 As a sintering aid, add an appropriate amount of alcohol to reduce the viscosity of the slurry. Ball mill for 30 minutes using a vibrating ball mill.

[0037] 2. Brush the mixed slurry onto the surface of the C / SiC sample, and cure it at 120°C for 8 hours.

[0038] 3. Pass argon as a protective gas in a vacuum tube furnace, and heat-treat at 1250°C for 2 hours. can get dense Sc 2 Si 2 o 7 coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com