A kind of method of olefin hydroformylation reaction in ionic liquid solvent

An ionic liquid solvent and ionic liquid technology, applied in carbon monoxide reaction preparation, chemical instruments and methods, organic chemistry, etc., to achieve high yield, low dosage and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

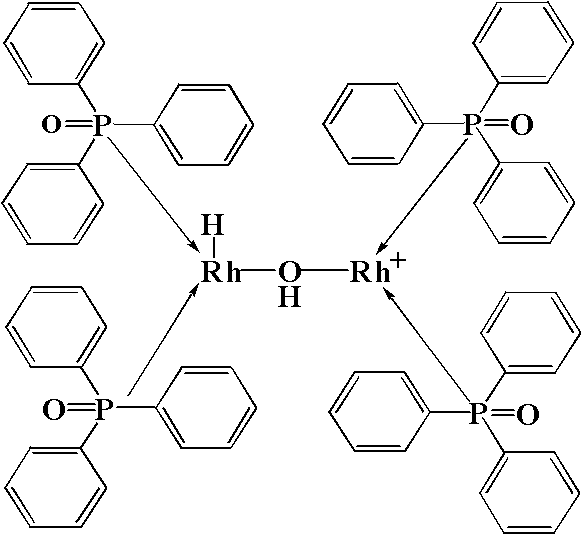

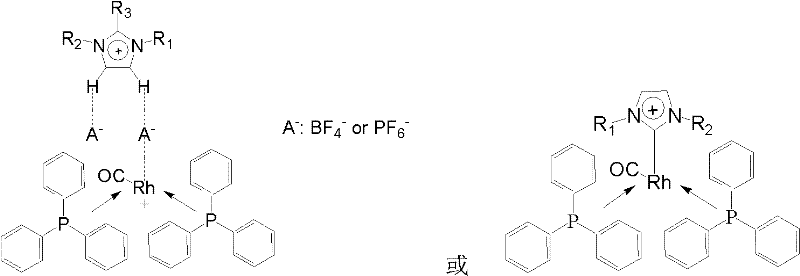

Method used

Image

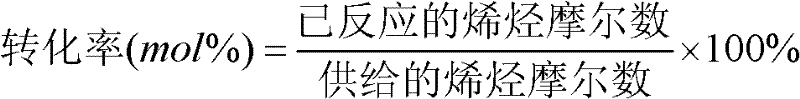

Examples

Embodiment 1

[0026] 0.0078g (about 0.03mmol) Rh(CO) 2 acac catalyst, 0.0786g (about 0.3mmol) triphenylphosphine, 10mL of degassed toluene, added to a self-made 200mL stainless steel reactor with a polytetrafluoroethylene liner, nitrogen replacement 3 times at room temperature, filled with mole than C 2 h 4 :CO:H 2 1:1:1 to 2.0MPa. React at 100°C for 2 hours, cool to room temperature and release unreacted gas, the prepared propionaldehyde and other by-products are analyzed by gas chromatography, the experimental results are shown in Table 1.

Embodiment 2

[0036] HRh(CO)(PPh 3 ) 3 Catalyst preparation

[0037] Place 0.527g (2mmol) of triphenylphosphine in a 50ml three-necked flask equipped with a condenser, vacuumize and fill with nitrogen three times to make it an inert and oxygen-free environment. Use a pipette needle to add 20ml of absolute ethanol to it, stir and heat to reflux (70°C), add a solution of 0.0527g (0.2mmol) RhCl 3 · 3H2O in 4ml ethanol solution, stirred rapidly for 15 seconds, turned into (deep red solution). Add 2ml of 40% formaldehyde solution, the dark red solution becomes lighter. Then heat 4ml of absolute ethanol dissolved with 0.16g KOH until it is about to boil, then use a pipette needle to add to the reaction solution, within 3 minutes the deep red solution gradually turns yellow, reflux for 10 minutes, cool to room temperature, and yellow precipitates powdery solid. Use a pipette needle to remove the liquid-phase solvent, wash the solid product with 10ml of absolute ethanol and 10ml of distilled w...

Embodiment 3

[0046] Catalyst, raw material, ionic liquid and reaction condition identical with comparative example 6, just use ionic liquid [Bmim] [BF 4 ] replaced with [Bmmim][BF 4 ] to prepare propionaldehyde, the experimental results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com