A semi-solid vibration assisted brazing equipment

A semi-solid, brazing technology, used in welding equipment, metal processing equipment, metal processing, etc., can solve the problems of easy gas involvement, difficult to achieve automation, difficult to control the connection process, etc., to achieve the effect of high-quality welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

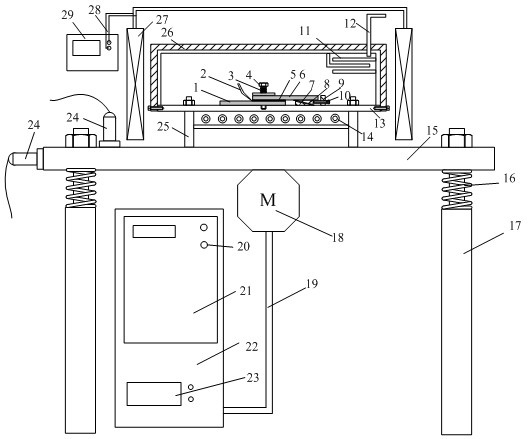

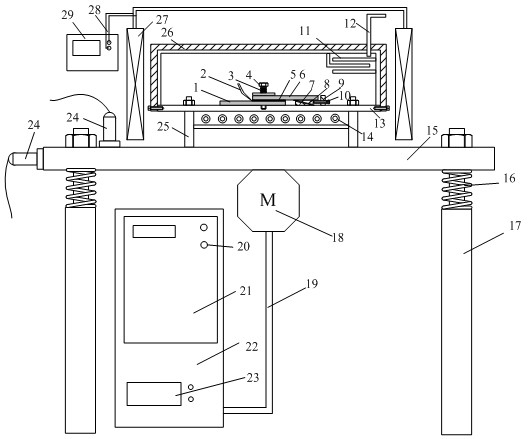

[0033] Below in conjunction with accompanying drawing, further illustrate the structure of the present invention namely mode of operation:

[0034] see figure 1 , The brazing equipment includes a welding part, a mechanical vibration part, an electromagnetic vibration part and a control part. in:

[0035] The welding part includes a welding platform 15, a shielding gas cover 26, a thermocouple 2, a heating pipe 14 and a ventilation pipe 12; Above, the thermocouple 2 is arranged in the protective gas cover 26, one end is connected with the upper weldment 6 or the lower weldment 1, and the other end is connected with the temperature control panel 23 of the control part; the protective gas cover 26 is connected with a ventilation pipe 12 . The shielding gas cover 17 is made up of two layers of materials, the outer layer is a thermal insulation material, and the inner layer is a heating element. A gas heat conduction plate 11 is installed in the heating element of the inner lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com