A kind of unsaturated polyester fiberglass mat molded board and its production method

A technology of polyester glass fiber and glass fiber mat, which is applied in the field of unsaturated polyester fiber mat and its production, can solve the problems of mechanical properties, product thickness tolerance, dimensional stability, etc., and achieve excellent electrical insulation performance and corrosion resistance , avoid the entry of halogen, improve the effect of compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

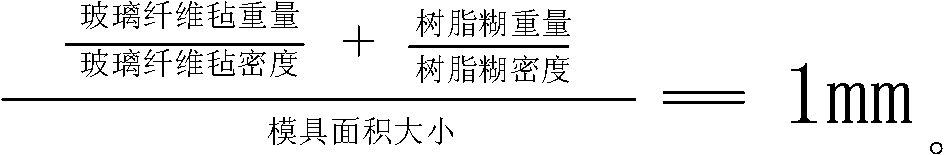

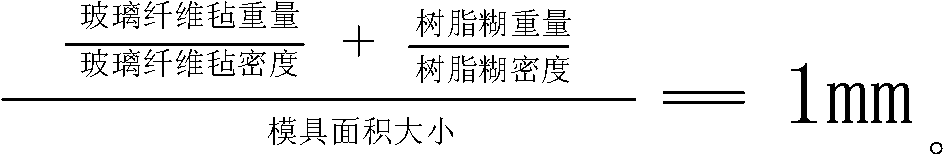

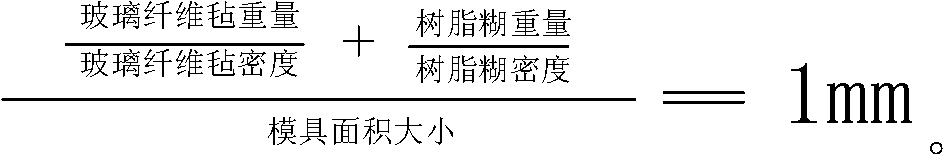

Method used

Image

Examples

Embodiment 1

[0044] Table 1

[0045] Unsaturated polyester resin

90KG

Low Shrinkage Additive

10KG

Polymerization inhibitor

1KG

4KG

thickener

1.6KG

color paste

5KG

crosslinking agent

0.5KG

Hardener

1KG

3KG

Auxiliary

2KG

filler

150KG

brightener

0KG

[0046] According to the formula in Table 1, according to the above production process, add 90 kg of o-phthalic unsaturated polyester resin in sequence and proportion, 10 kg of polyvinyl chloride low-shrinkage additive, stir the disperser at 500 rpm for 5 minutes, and add 1 kg of benzoquinone , 4 kg of zinc stearate, 0.5 kg of styrene, 1 kg of tert-butyl peroxybenzoate, 3 kg of BYK9010 viscosity reducer, 2 kg of BYK9065 additives, stirred at 1000 rpm for 5 minutes to stir evenly, and then added hydroxide 150 kilograms of aluminum, 5 kilograms of red color paste, speed is 1500 rev / mins, stirs...

Embodiment 2

[0055] table 3

[0056] Unsaturated polyester resin

70KG

Low Shrinkage Additive

30KG

Polymerization inhibitor

1KG

4KG

thickener

1.5KG

color paste

6KG

crosslinking agent

0.5KG

Hardener

1KG

4KG

Auxiliary

2.5KG

filler

200KG

brightener

0KG

[0057] According to the formula in Table 3, add 70 kg of o-phthalic unsaturated polyester resin in sequence and proportion according to the above production process, 30 kg of polyvinyl acetate low-shrinkage additive, stir at 500 rpm for 5 minutes with the disperser, and add 1 kg of benzoquinone , 4 kg of zinc stearate, 0.5 kg of styrene, 1 kg of tert-butyl peroxybenzoate, 4 kg of BYK9010 viscosity reducer, 2.5 kg of BYK9065 additives, stirred at 1000 rpm for 5 minutes to stir evenly, and then added hydroxide 150 kilograms of aluminum and 50 kilograms of kaolin, red color paste, speed is 1...

Embodiment 3

[0065] table 5

[0066] Unsaturated polyester resin

90KG

Low Shrinkage Additive

10KG

Polymerization inhibitor

1KG

4KG

thickener

1.6KG

color paste

5KG

crosslinking agent

0.5KG

Hardener

1KG

Viscosity reducer

3KG

Auxiliary

2KG

filler

150KG

brightener

0KG

[0067]According to the formula in Table 5, add 90 kg of o-phthalic unsaturated polyester resin in order and proportion according to the above production process, 10 kg of polymethyl methacrylate low-shrinkage additive, stir the disperser at 500 rpm for 5 minutes, add benzene 1 kg of quinone, 4 kg of zinc stearate, 0.5 kg of styrene, 1 kg of tert-butyl peroxybenzoate, 3 kg of BYK9010 viscosity reducer, 2 kg of BYK9065 auxiliary agent, stirred at 1000 rpm for 5 minutes, and then Add 150 kilograms of aluminum hydroxide, 5 kilograms of red color paste, the speed is 1500 rpm, stir for 5 minutes,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com