Attapulgite-based carbon composite ceramsite, its preparation method and use

A technology of attapulgite clay and attapulgite, applied in ceramic products, other household utensils, applications, etc., can solve the problems of inability to achieve energy saving and environmental protection, poor filtration characteristics, and inability to perform adsorption, and achieve excellent environmental adaptability, raw materials The effect of wide source and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] In the present embodiment, the raw materials of attapulgite-based carbon composite ceramsite are constituted by mass percentage: attapulgite clay 75%, leaves 15%, industrial water glass 10%;

[0032] In this example, the attapulgite-based carbon composite ceramsite is prepared according to the following steps:

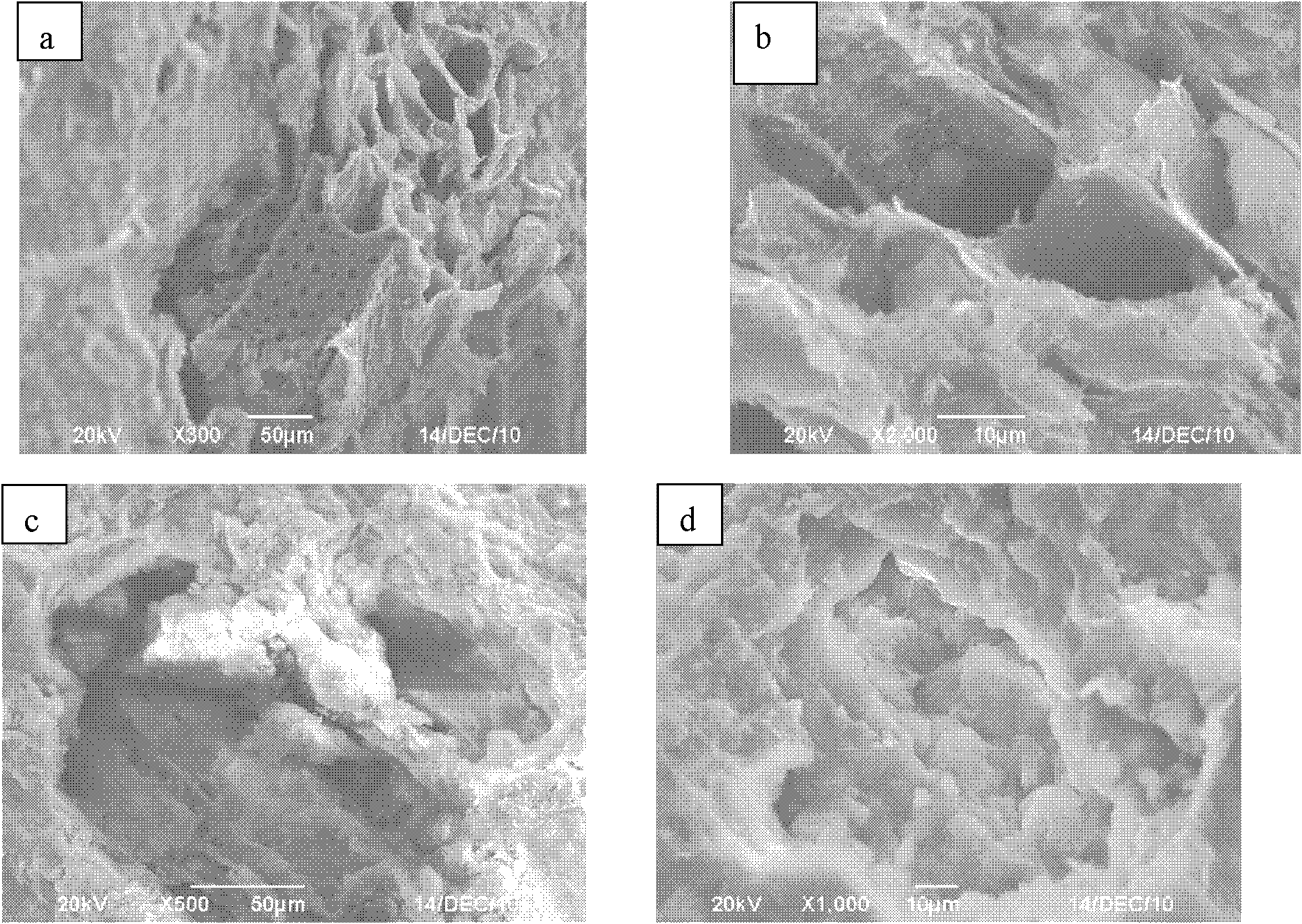

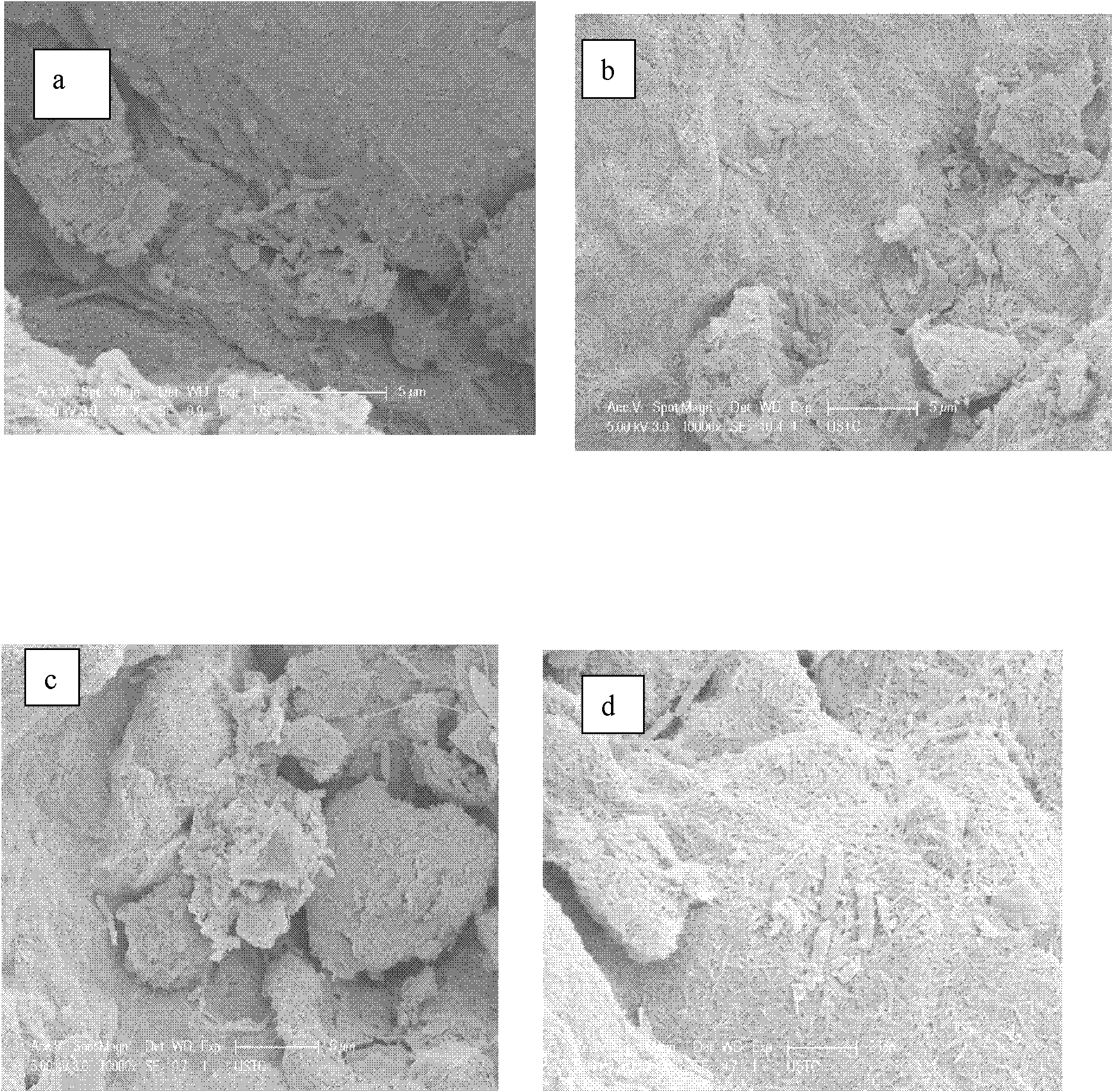

[0033] a, drying and pulverizing the attapulgite clay ore and passing through a 200-mesh sieve to obtain attapulgite powder;

[0034] B, the leaves are pulverized through a 200 mesh sieve, mixed with industrial water glass and the attapulgite powder obtained in step a to obtain a mixed powder;

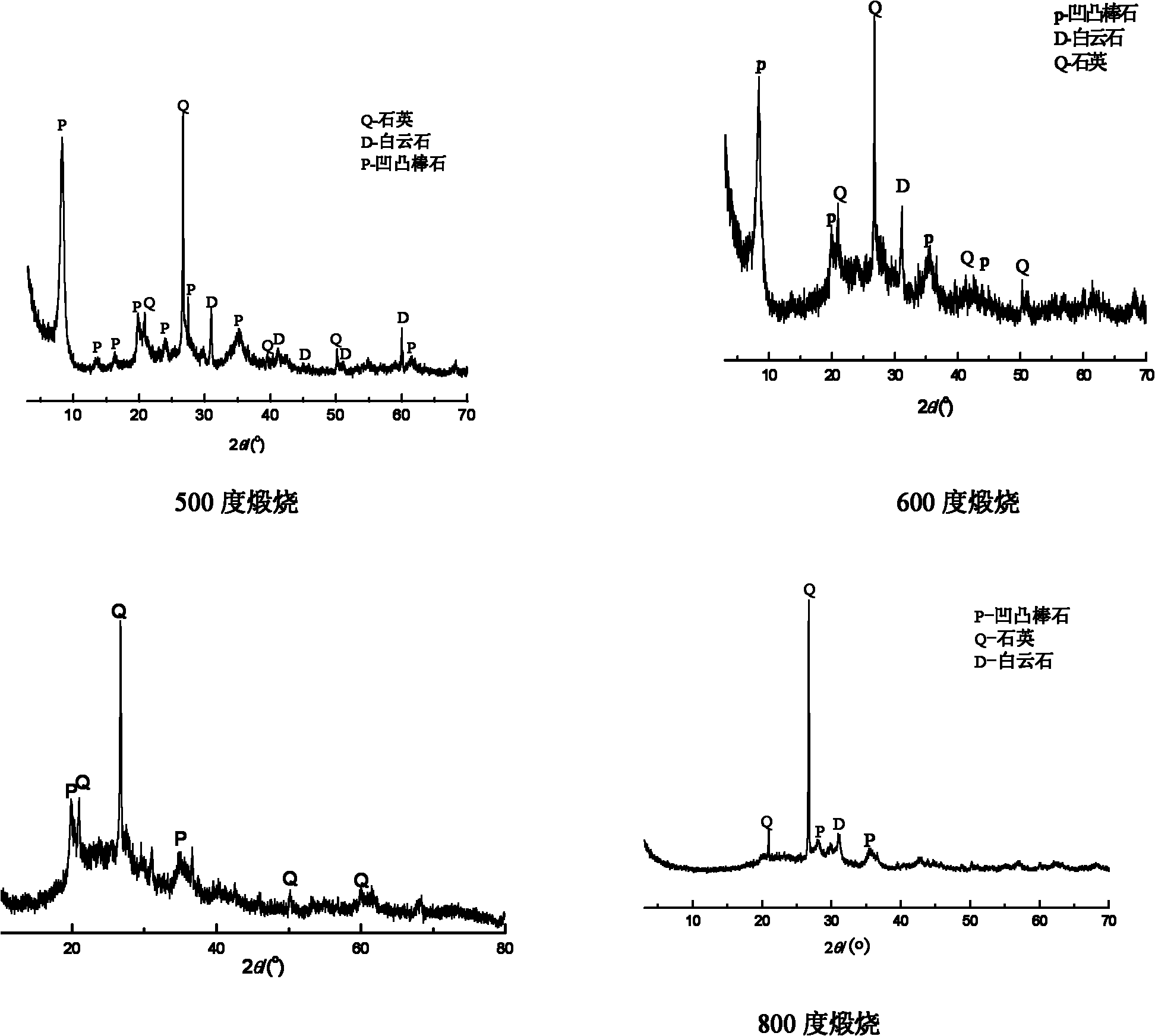

[0035] c. Add water to the mixed powder and stir evenly, the amount of water added is 30% of the mass of the mixed powder, granulate and shape, control the particle size at 5-7mm, then dry naturally, and then calcined at 600°C under nitrogen atmosphere Attapulgite-based carbon composite ceramsite was obtained in 3 hours.

[0036] Using the attapulgite-based carbon comp...

Embodiment 2

[0041] In this embodiment, the raw materials of attapulgite-based carbon composite ceramsite are constituted by mass percentage: attapulgite clay 85%, sawdust 10%, industrial water glass 5%;

[0042] In this example, the attapulgite-based carbon composite ceramsite is prepared according to the following steps:

[0043] a, drying and pulverizing the attapulgite clay ore and passing through a 200-mesh sieve to obtain attapulgite powder;

[0044] B, the sawdust is pulverized through a 200 mesh sieve, mixed with industrial water glass and the attapulgite powder obtained in step a to obtain a mixed powder;

[0045] c. Add water to the mixed powder and stir evenly, the amount of water added is 50% of the mass of the mixed powder, granulate and shape, control the particle size at 5-7mm, then dry naturally, and then store at 500 ° C under an argon atmosphere Calcined for 1 hour to obtain attapulgite-based carbon composite ceramsite.

[0046] The attapulgite-based carbon composite ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com