A kind of high-performance foamed polyethylene sheet and preparation method thereof

A foamed polyethylene, high-performance technology, applied in the field of high-performance foamed polyethylene sheet and its preparation, can solve the problem of inability to meet the protection requirements of high-end electrical appliances and precision instruments, low density and surface hardness, and easy to be pierced by sharp objects Wear and other problems, to achieve the effect of long sustainable use time, excellent heat resistance and low temperature resistance, good resilience and shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

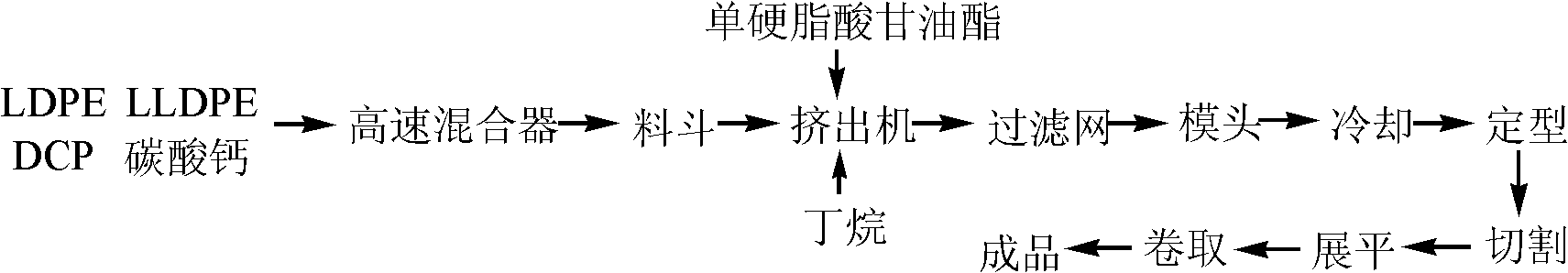

Method used

Image

Examples

Embodiment 1

[0029] 1) 40kgLDPE, 10kgLLDPE, 0.01kgDCP and 0.3kg talc powder are sucked into the hopper of the extruder through a vacuum feeder, and then fall into the barrel of the extruder, and then enter the homogenization section after being transported and melted.

[0030] 2) Add 100ml of butane and 24g of glyceryl monostearate (melted) before the homogenization section with a high-pressure metering pump, and the various materials are fully contacted and mixed in the homogenization section, so that the additives and butane are evenly dispersed in the melt.

[0031] 3) Extrude through the filter, foam, cool, shape, flatten, pull, and roll to obtain the product.

[0032] 4) Density measurement: cut the foamed polyethylene sheet, measure its length (l), width (w), height (h), and then measure its weight (m), then the density ρ=m / (l*w*h)

[0033] Surface hardness measurement: measured by Shore hardness tester.

[0034] The experimental results are shown in the table.

[0035] Table 1

...

Embodiment 2

[0038] As described in Example 1, step 1) is changed to: 45kgLDPE, 5kgLLDPE, 0.01kgDCP and 0.5kg talcum powder are sucked into the hopper of the extruder through a vacuum feeder, so that they fall into the barrel of the extruder, and after conveying, The melt enters the homogenization section. The experimental results are shown in Table 2:

[0039] Table 2

[0040] Density (g / m 3 )

Embodiment 3

[0042] As described in Example 1, step 1) is changed to: 30kgLDPE, 20kgLLDPE, 0.015kgDCP and 0.6kg light calcium carbonate are sucked into the hopper of the extruder through a vacuum feeder to make it fall into the barrel of the extruder. Conveying and melting into the homogenization section. The experimental results are shown in Table 3:

[0043] table 3

[0044] Density (g / m 3 )

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com