Flame-retardant polysulfide sealant and preparation method thereof

A polysulfide sealant, flame-retardant technology, applied in chemical instruments and methods, adhesives, other chemical processes, etc., can solve the problem of poor flame retardancy of two-component polysulfide sealant, achieve good flame-retardant effect, add Small amount, avoiding the effect of flammability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

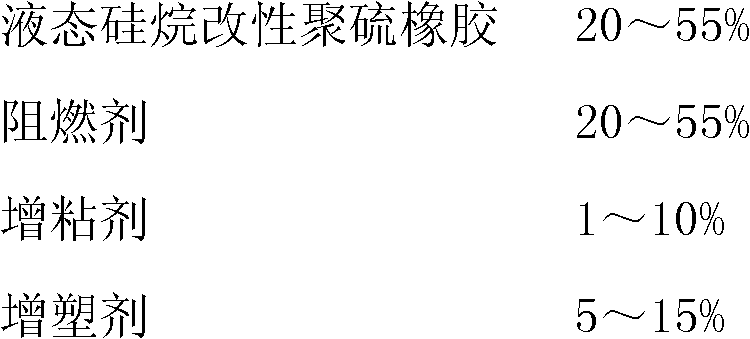

preparation example Construction

[0036] The preparation method of the above-mentioned flame-retardant polysulfide sealant is as follows:

[0037] Dry the filler and flame retardant at 60-80°C for 1 hour; put the dried filler, flame retardant, liquid silane-modified polysulfide rubber, tackifier, and plasticizer into the kneader and mix evenly. The paste is ground by a colloid mill, and then dehydrated in a reactor under vacuum to obtain the one-component flame-retardant polysulfide sealant.

[0038] In the polysulfide sealant in the embodiment of the present invention, the flame retardant formed by compounding flame-retardant graphite and antimony trioxide is used as a flame-retardant system, and the amount of addition is small, so that the density of the sealant is small and the consumption per unit volume is small; The sealant has good flame retardant effect, the oxygen index is greater than 34%, and meets the FV-0 standard, and the sealant does not contain volatile components, and will not corrode glass, s...

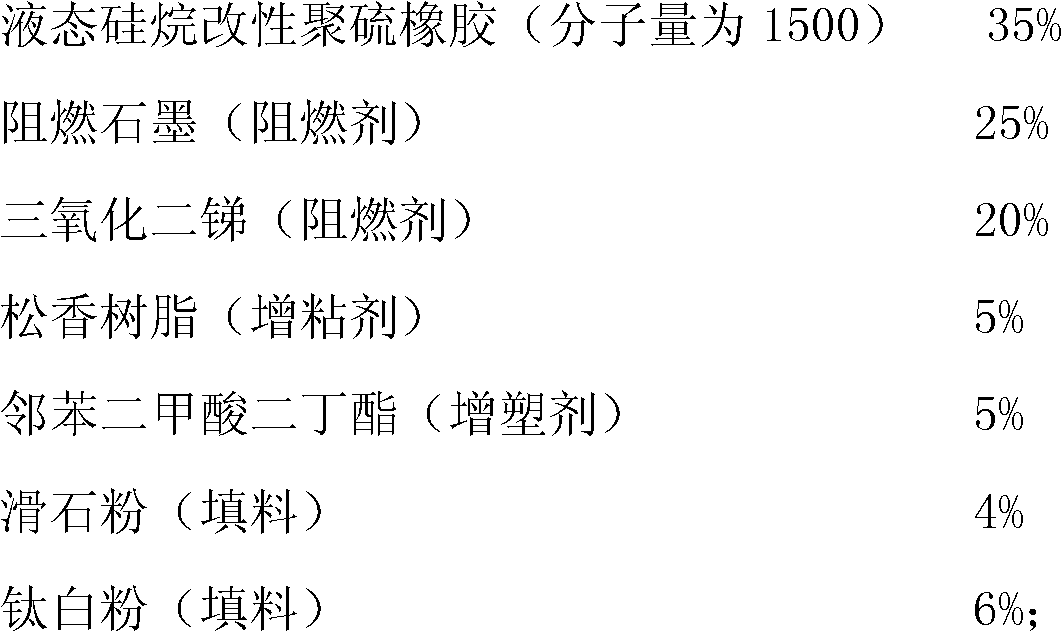

Embodiment 1

[0041] This embodiment provides a flame-retardant polysulfide sealant, which is a single-component polysulfide sealant. The amount of each raw material (by mass percentage) of the sealant is:

[0042]

[0043] The preparation method of the above-mentioned sealant is as follows: dry flame-retardant graphite, antimony trioxide, barium titanate, and calcium carbonate at 60-80°C for 1 hour; dry liquid silane-modified polysulfide rubber, dibutyl phthalate , rosin resin, dried filler and flame retardant are put into a kneader and mixed evenly. The mixed paste is ground by a colloid mill, and then dehydrated in a reactor under vacuum to obtain a one-component flame-retardant polymer. Sulfur sealant.

Embodiment 2

[0045] This embodiment provides a flame-retardant polysulfide sealant, which is a single-component polysulfide sealant. The amount of each raw material (by mass percentage) of the sealant is:

[0046]

[0047] The preparation method of above-mentioned sealant is as follows:

[0048] Dry flame-retardant graphite, antimony trioxide, kaolin, and carbon black at 60-80°C for one hour; dry liquid silane-modified polysulfide rubber, dioctyl phthalate, terpene resin, and dried filler 1. The flame retardant is put into a kneader and mixed evenly. The mixed paste is ground by a colloid mill, and then dehydrated in a reactor under vacuum to obtain a one-component flame-retardant polysulfide sealant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com